Woven fabric for non-metallic soles for safety footwear, and resulting sole

A non-metal, safety shoe technology, applied in the field of warp and weft fabrics, to achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The single layer composite fabric of the present invention is characterized in that it provides a very compact structure such that the greater the number of warp and weft yarns contained therein, the higher will be the manufacturing and material costs, but it will provide greater mechanical strength.

[0033] In all the embodiments shown, the fabric of the invention consists of several strands joined along their entire extension and obtained during the actual warp and weft weaving without having to be subsequently assembled.

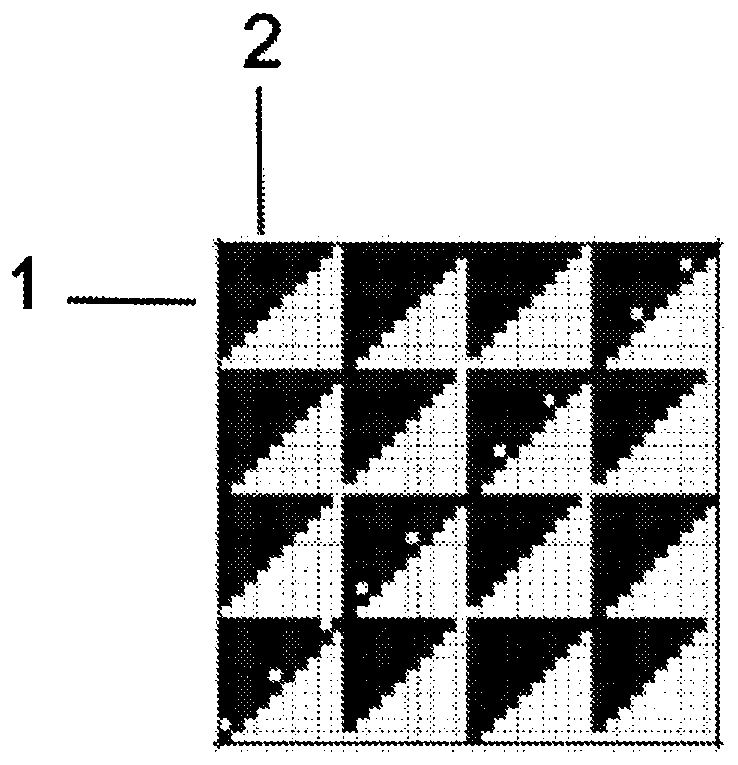

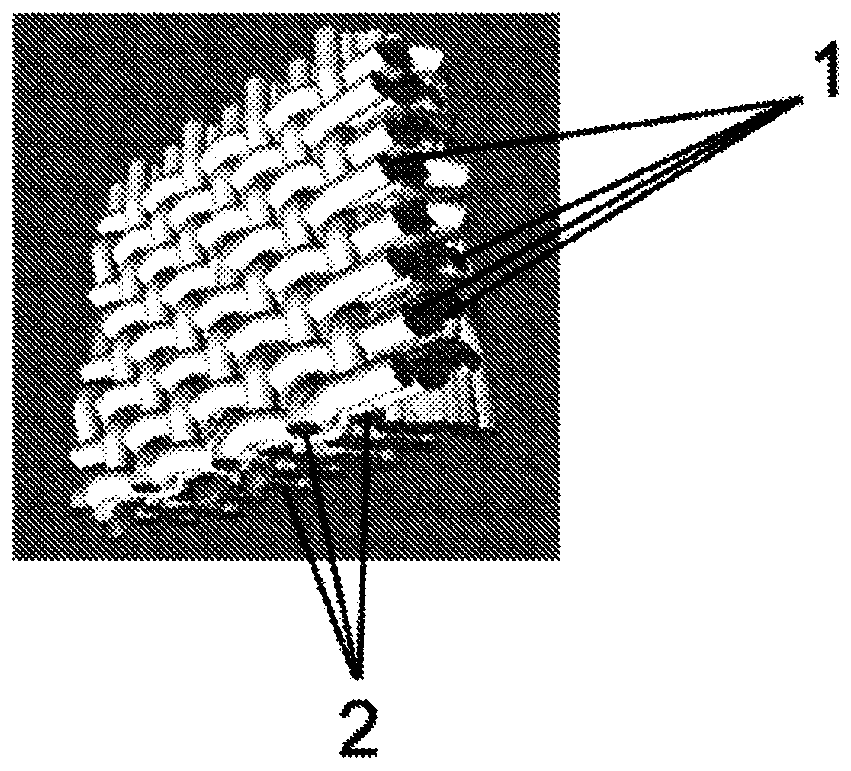

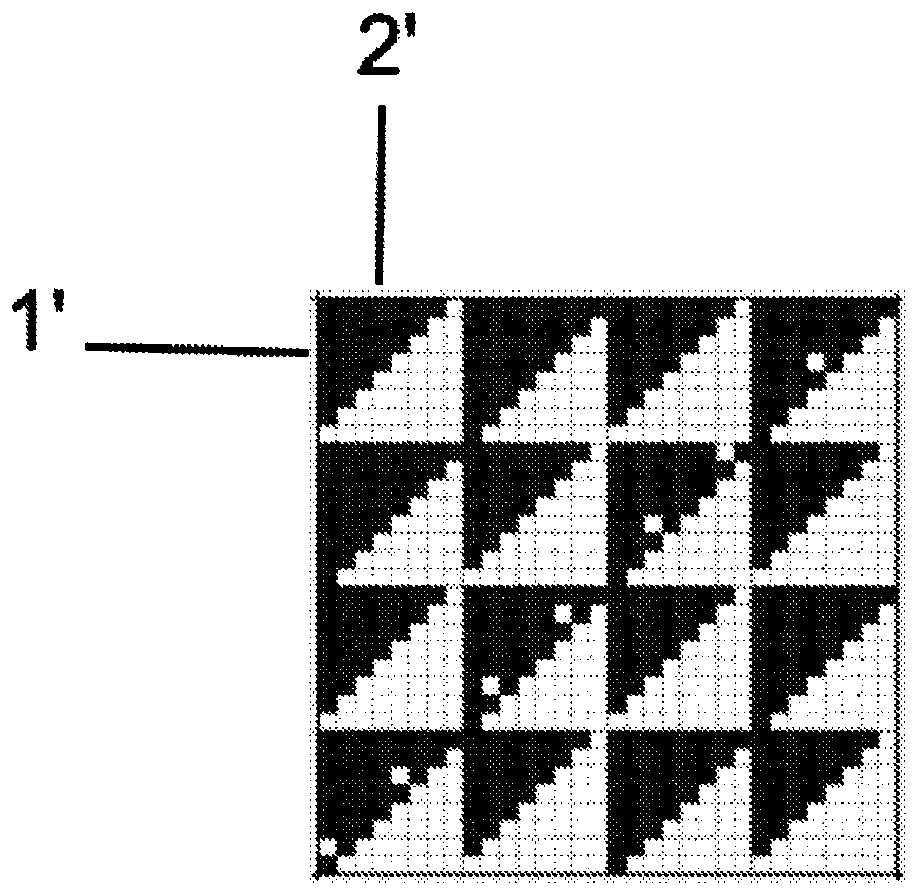

[0034] therefore, figure 1 depicts the fabric structure of the present invention with up to ten strands, while figure 2 depicts figure 1 3D simulation of tissue.

[0035] therefore, figure 2 Depicted are 10 weft woven yarns (1 ) and 10 warp woven yarns (2) for fabrics with up to ten plies. It is true, however, that in the simulations obtained for this particular embodiment it was not possible to clearly identify each of the 10 yarns forming ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com