Scrap iron removal equipment

A technology for cleaning equipment and iron filings, which is applied in the direction of metal processing equipment, metal processing machinery parts, maintenance and safety accessories, etc., and can solve problems such as laborious cleaning of debris, inability to clean debris quickly, large and long debris, etc. , to achieve the effects of convenient operation, reduced impact, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

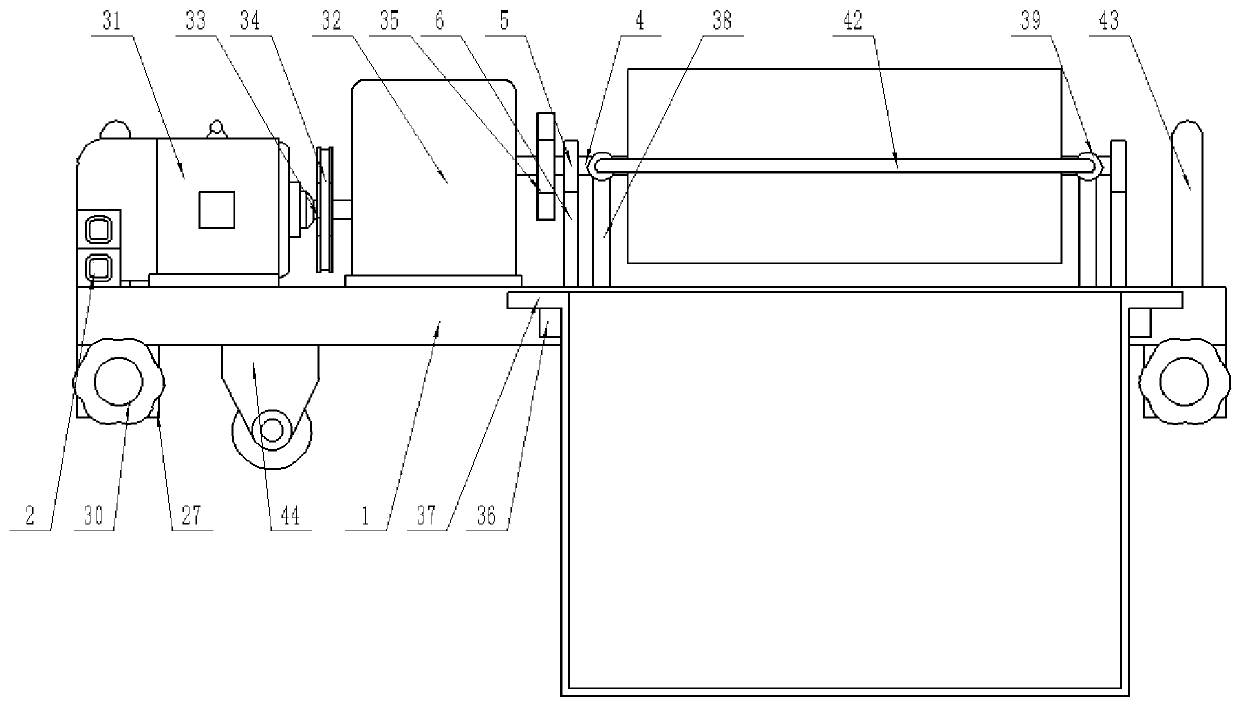

[0024] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-6 As shown, in this implementation:

[0025] In this device, the device is powered by connecting with an external power supply, and the external power supply is electrically connected with the drive motor 31 for power supply. 31 is electrically connected, so as to control the operation of the device.

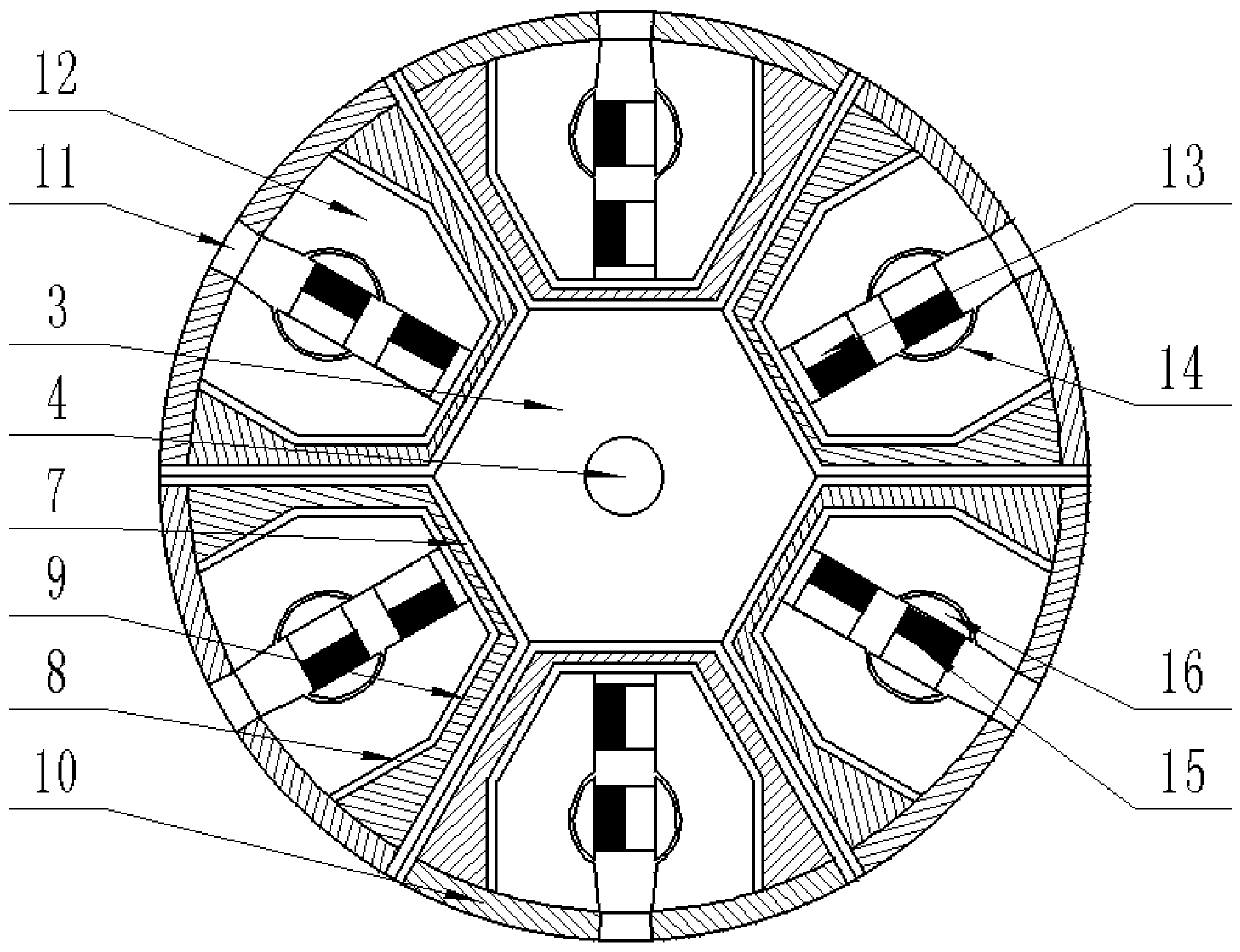

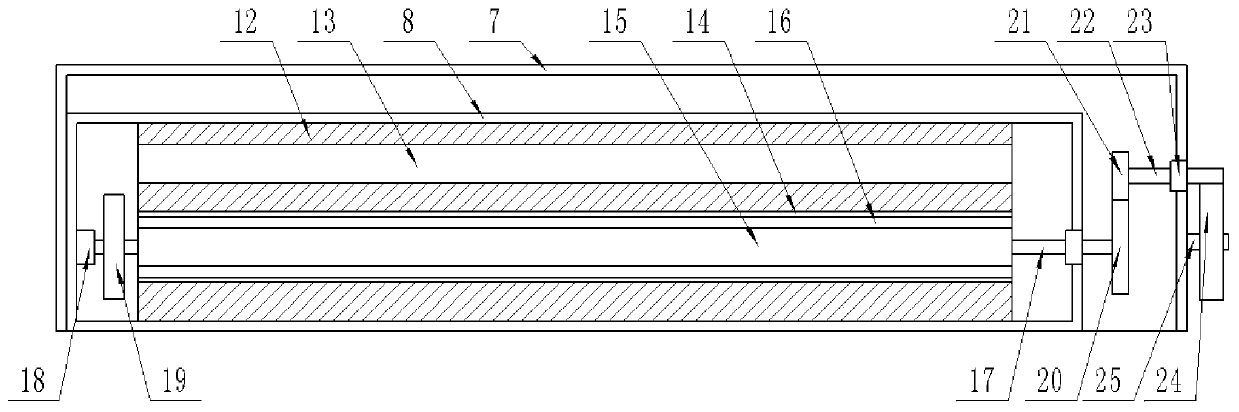

[0026] The invention of the present application lies in the structural design of the rotating chip cleaning device, combined with the attached figure 1 , attached figure 2 , attached image 3 And attached Figure 4 , the rotating chip cleaning device includes a regular hexagonal drum 3 at one end above the base 1, a rotating shaft 4 is installed in the regular hexagonal drum 3, two rotating bearings 5 are installed at both ends of the rotating shaft 4, and the rotating bearing 5 is connected to the base 1 is connected by a rotating bearing seat 6, a trapezo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com