Comprehensive kitchen waste separator

A waste and separator technology, applied in the field of meal waste comprehensive separator, can solve the problem of no successful cases, and achieve the effect of beautiful appearance, compact structure, reducing equipment investment and planning land use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

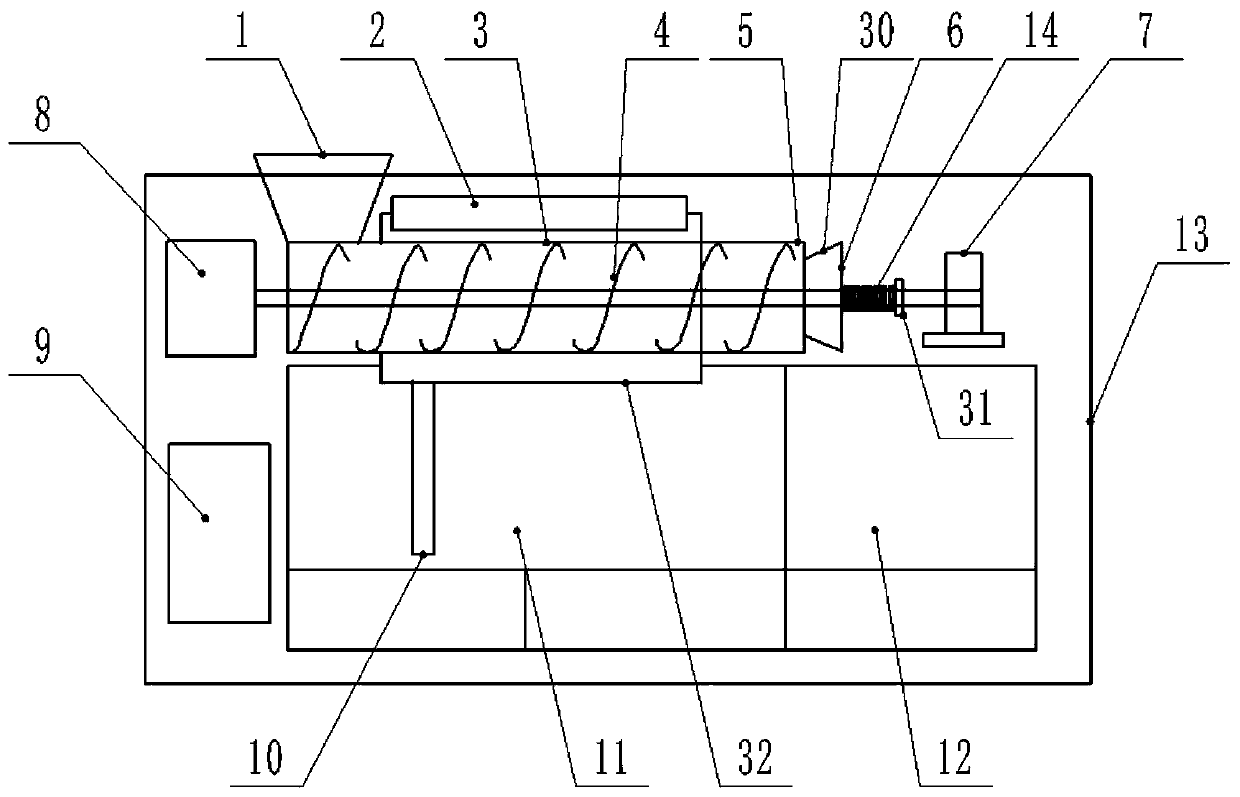

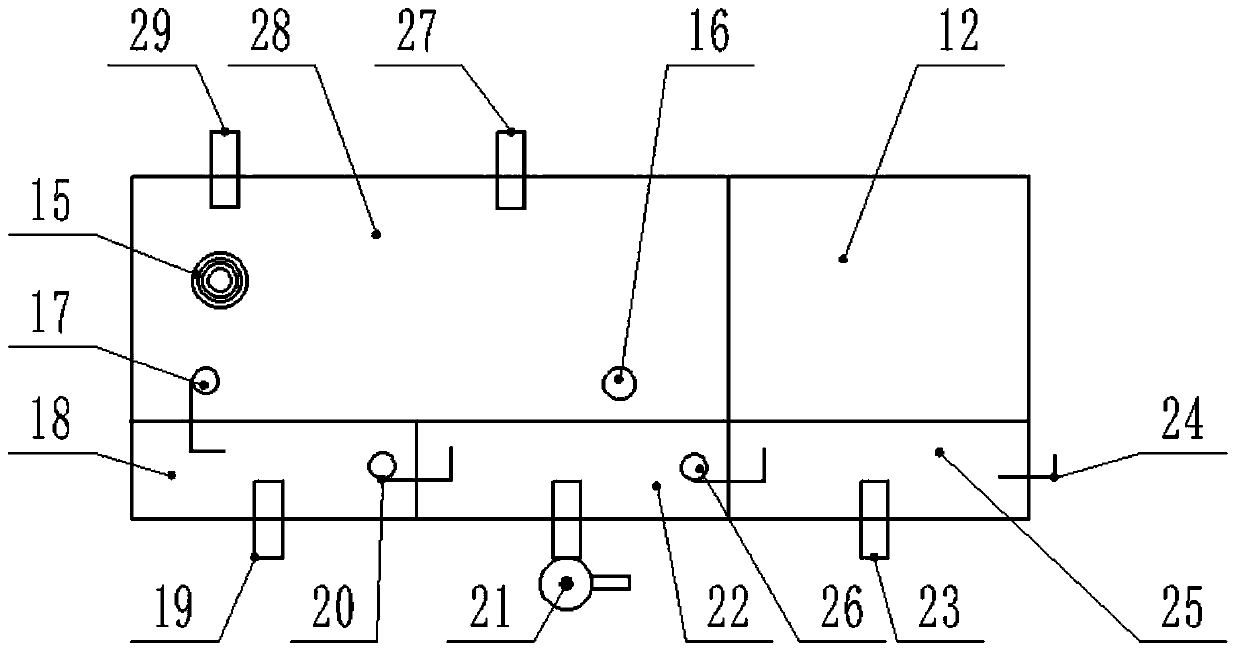

[0034] Example 1, such as Figure 1-2 As shown, a comprehensive food waste separator includes a main box 13, in which a squeeze box 5, an oil-water separation box 11 and a solid residue storage box 12 are arranged; the squeeze box The top of 5 is communicated with feed box 1, and the end is communicated with discharge box 30, and material baffle plate 6 is installed at the discharge opening of described discharge box 30, and described solid slag storage box 12 is positioned at the described discharge box Directly below;

[0035] A double-screw conveyor 4 mounted on a transmission rod is arranged inside the extrusion box 5. The first end of the transmission rod passes through the extrusion box to connect with the transmission motor and the reducer 8, and the end of the transmission rod passes through the extrusion box 5 in turn. 1. After the discharge box 30 and the baffle plate 6 are connected with the bearing seat 7, a mounting seat 31 is installed on the transmission rod be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com