High-rim section steel tubeless vehicle wheel without sealing ring and weld joint

A no-weld, no-sealing technology, applied to rims, vehicle parts, transportation and packaging, etc., can solve problems such as unsatisfactory installation of tubeless tires, poor performance of the wheel system, easy deviation of installation, etc., to achieve good practicability and Marketing value, overcoming overall strength defects, effect of profile and size optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

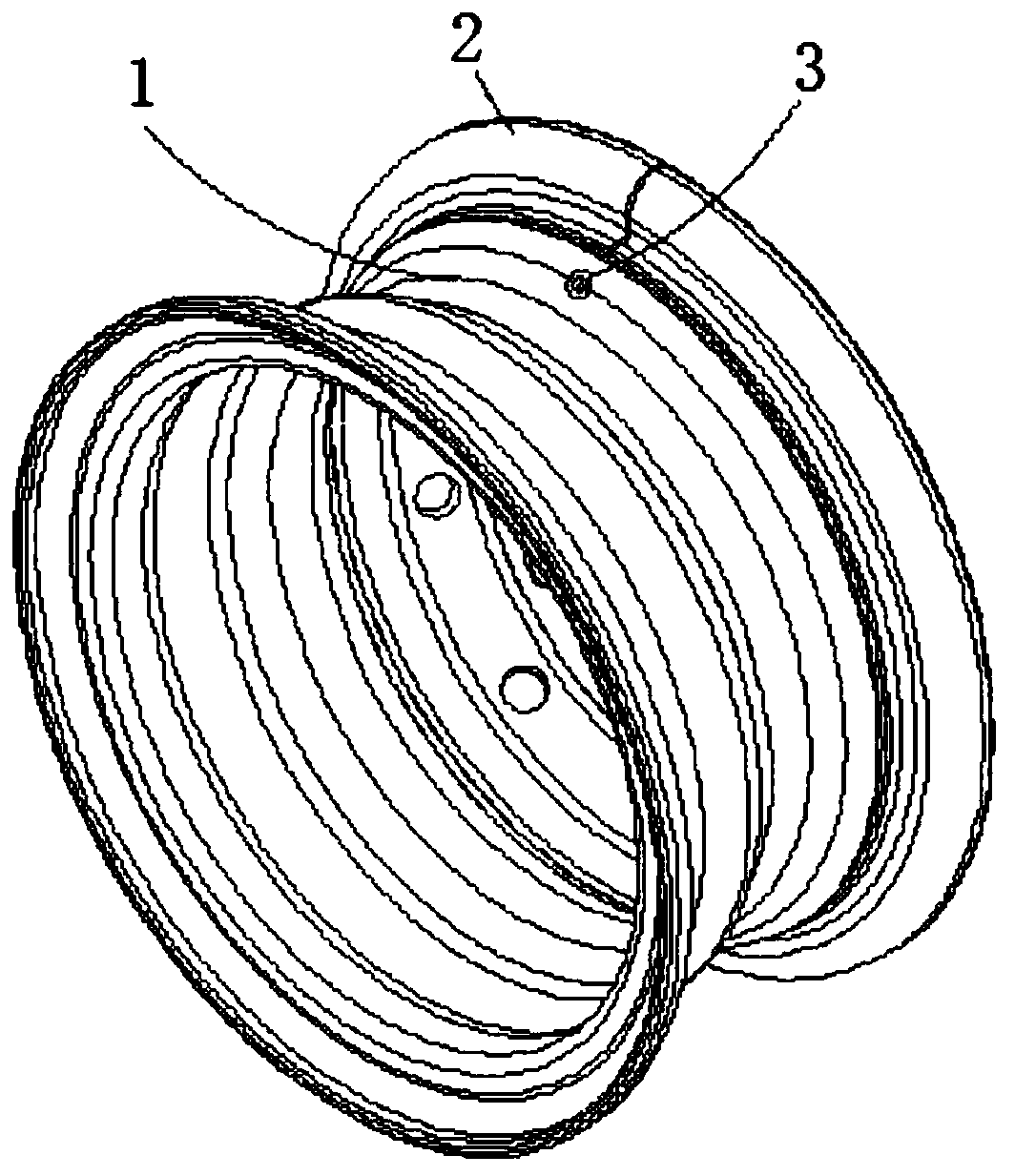

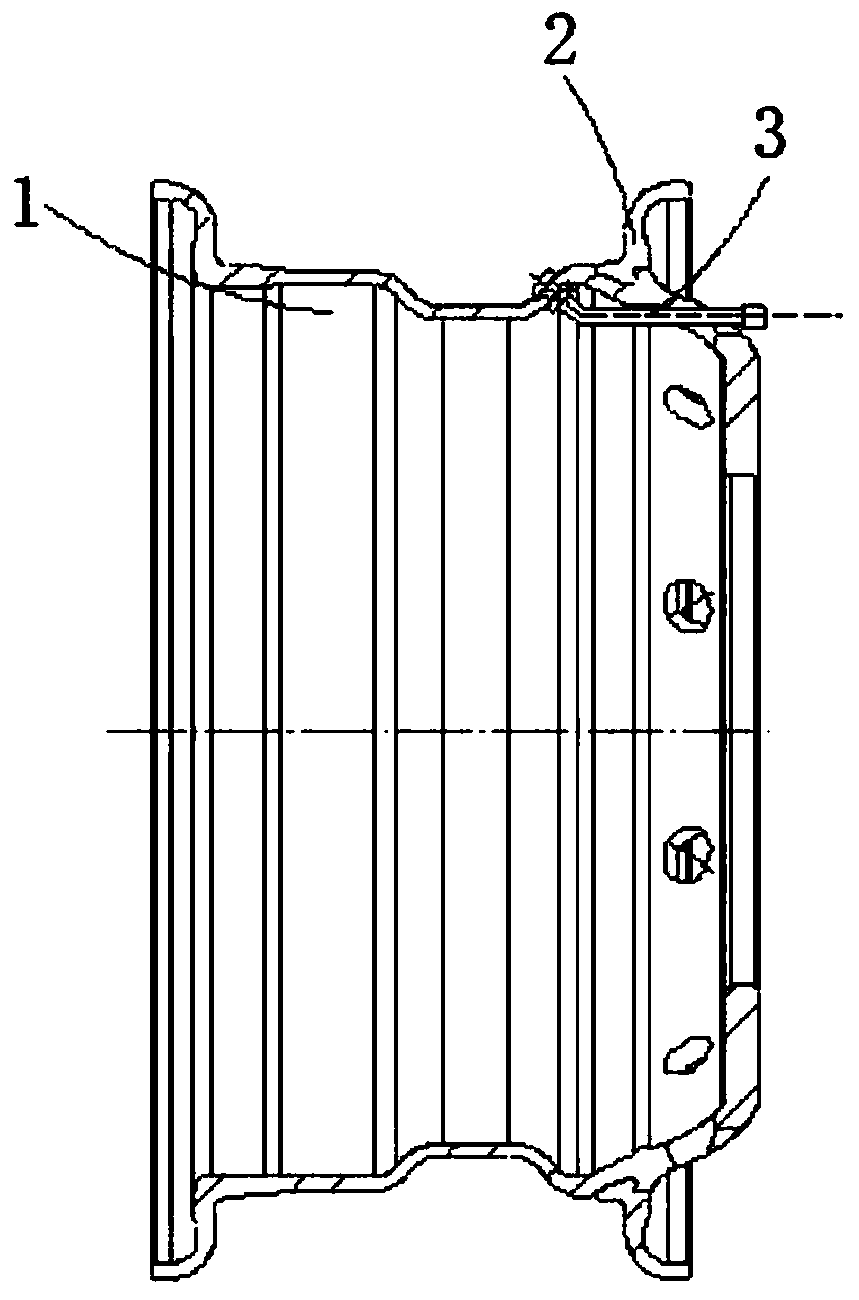

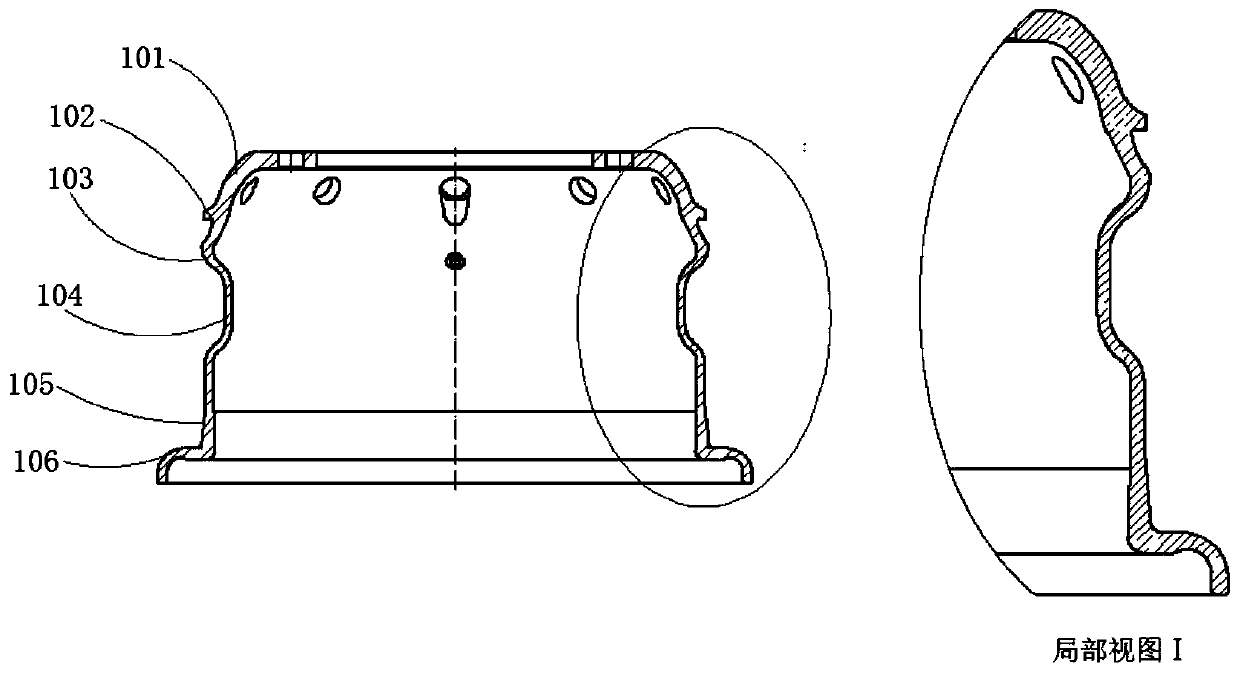

[0027] Refer below Figure 1 to Figure 5 To further explain this application, such as Figure 1-4 As shown, a weldless high rim steel tubeless wheel without sealing ring is composed of a wheel main body 1, an annular circlip and a valve core 3. The said wheel main body 1 includes a wheel spoke and a rim integrally formed by spinning , its strength and precision are greatly improved, and there is no welding seam on the rim and the joint between the rim and the spokes, which effectively overcomes the welding difficulties and overall strength defects brought about during the welding process, and greatly simplifies the process flow and production management of wheel manufacturing; A retaining ring groove 102 is provided between the spoke and the rim; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com