Electric pressurization type anti G suit

A kind of anti-G clothing and electric technology, which is applied in the field of electric pressurized anti-G clothing, can solve the problems of heavy weight and poor ventilation of the anti-G clothing, and achieve the effect of improving the combined efficiency of man and machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

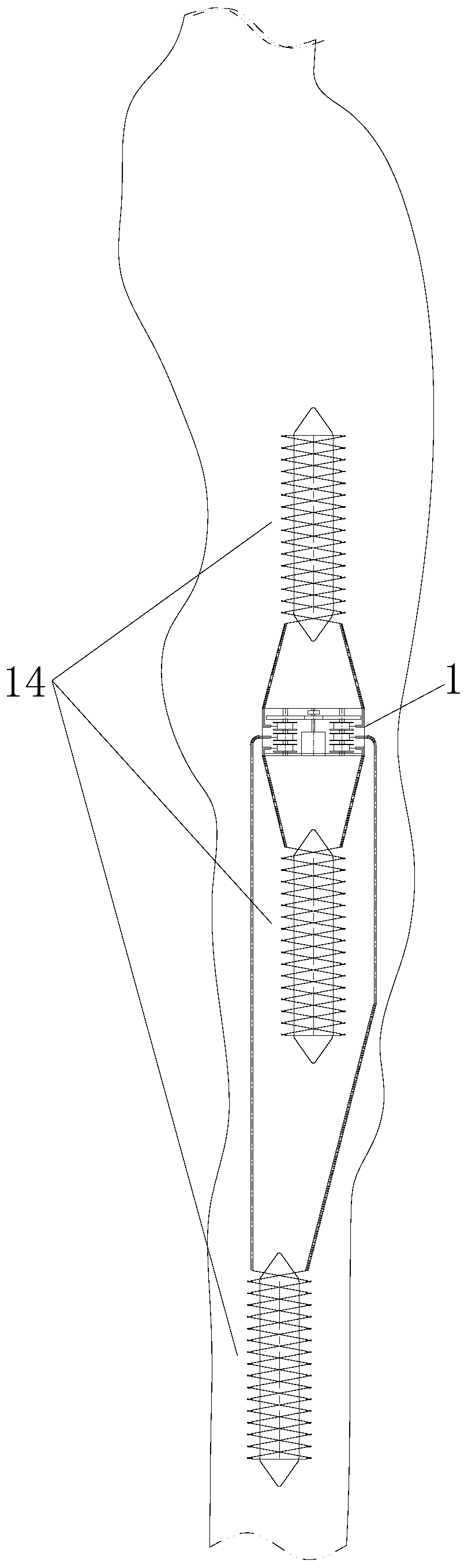

[0041] refer to figure 1 , an electric pressurized anti-G suit, including a pressurization component 1 arranged on the anti-g suit, and three tension components connected with the pressurization component 1; the three tension components are respectively arranged at the calf position of the anti-g suit, The position of the thigh and the position of the side waist, the pressure component 1 is located on the side of the crotch, and the three tension components are located on the same side of the human body of the pressure component 1, and the pressure component 1 controls the impact of the anti-G suit on the pilot's body through the tension component 14. Apply constant pressure.

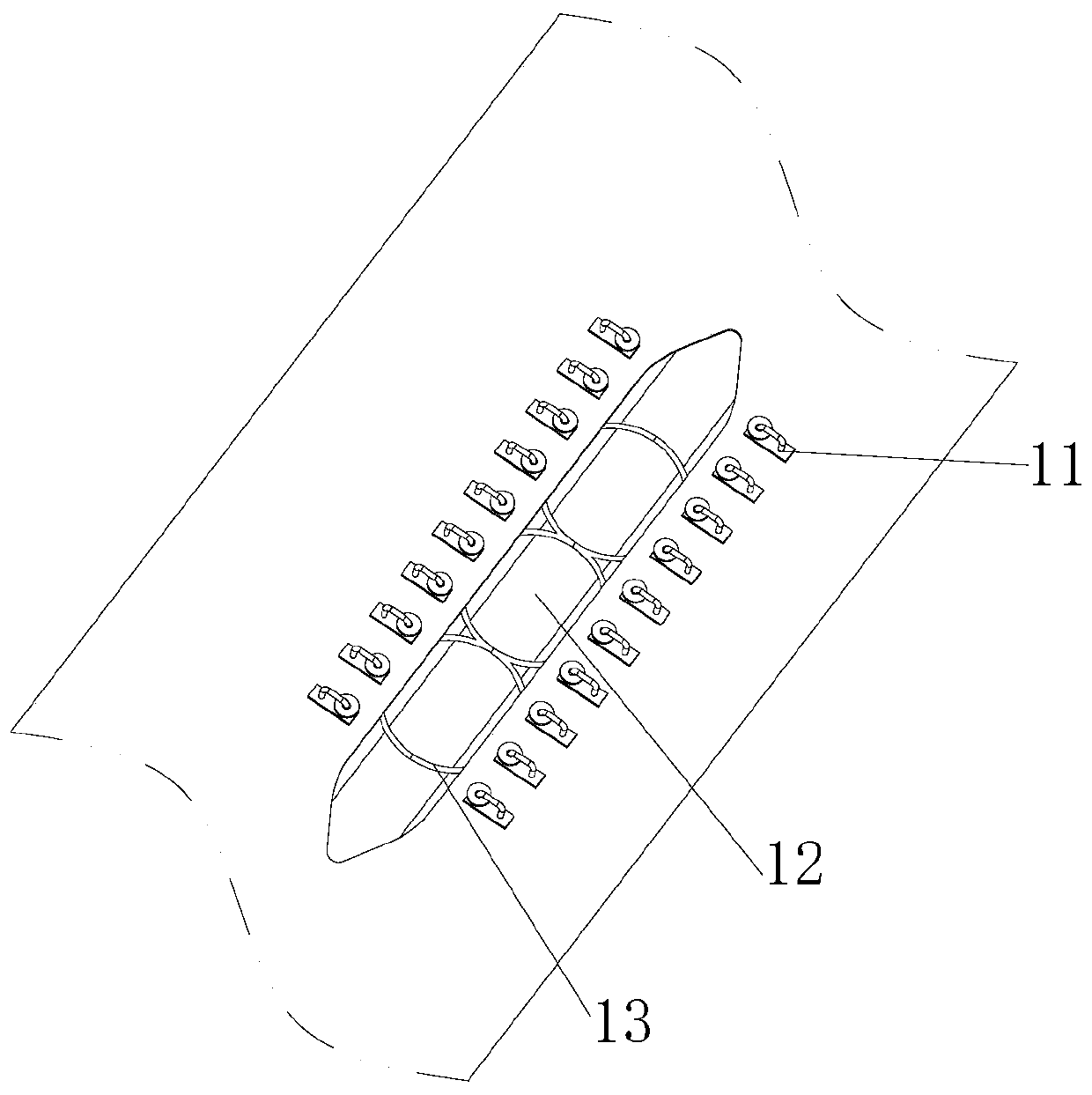

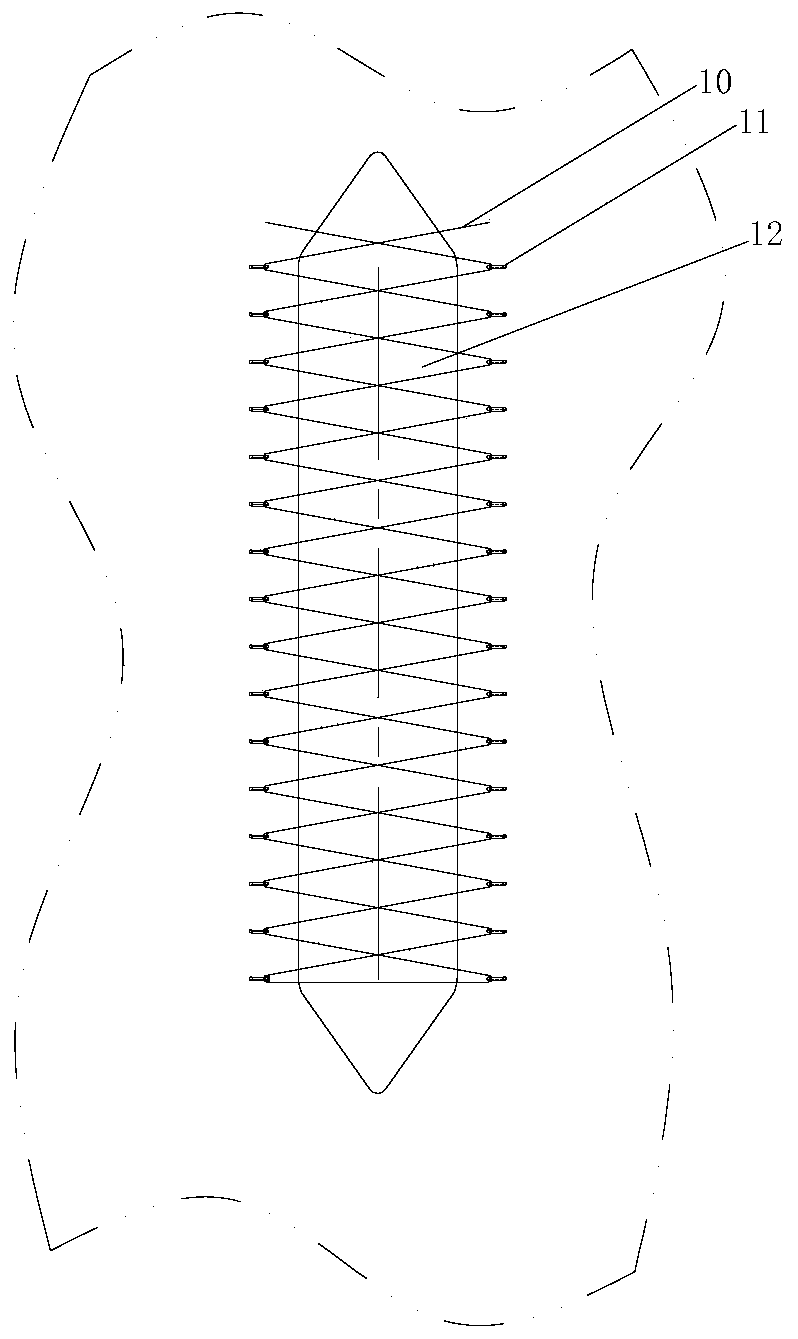

[0042] refer to Figure 2 to Figure 4 , the tension component 14 includes a tightening area 12 , a wire loop ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com