Explosive acceleration device

An acceleration device and explosive technology, applied in the field of explosive performance parameter experiments, can solve the problems of difficult scientific research, difficult to analyze the cause of accidents, and the inability to directly measure the dynamic mechanical properties of the impact of a bare explosive column, achieving low cost and low construction cost. , the effect of strong acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In this embodiment, an explosive accelerating device is designed to meet the acceleration of 9g explosive at 40m / s-250m / s.

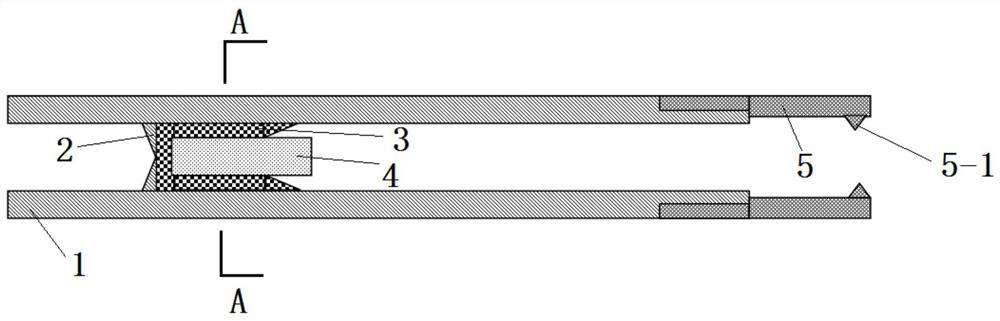

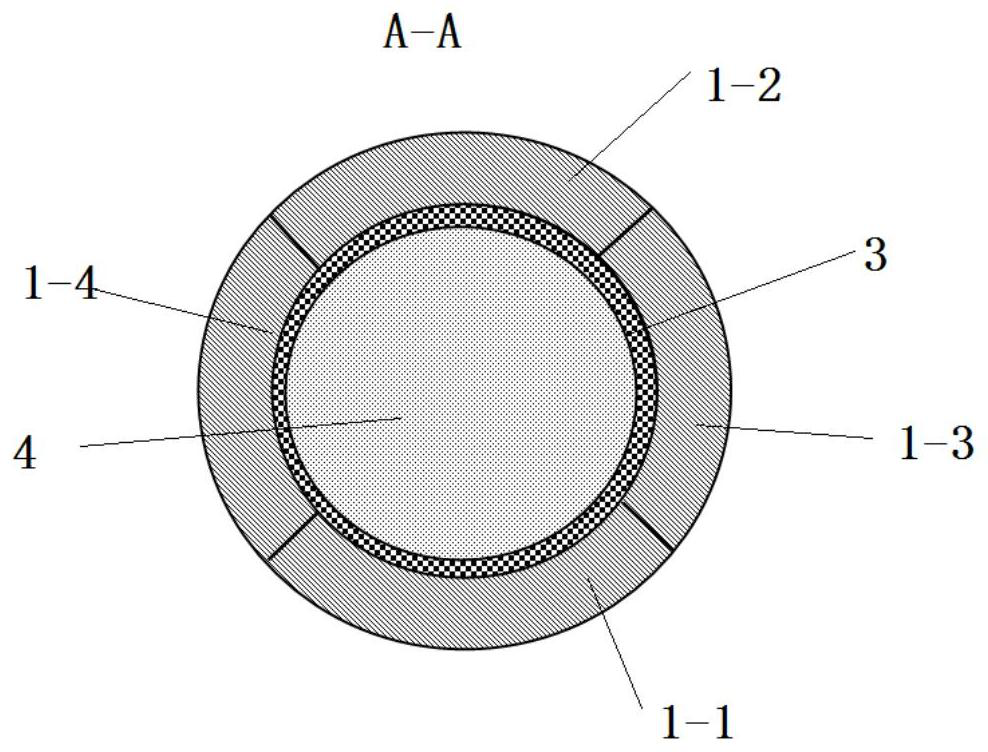

[0024] An explosive acceleration device, characterized in that: the device includes a guide rail 1, a slider 2, a housing 3, explosives 4 and a turning tool 5, the guide rail 1 is made of conductive metal, and the cross section of the guide rail 1 is circular , the guide rail 1 is composed of a positive rail 1-1, a negative rail 1-2, an insulating tape A1-3, and an insulating tape B1-4, and the positive rail 1-1, the negative rail 1-2, and the insulating tape A1-3 1. The cross section of the guide rail 1 is divided into four parts by the insulating tape B1-4. The insulating tape A1-3 and the insulating tape B1-4 serve the dual purpose of observing the window and isolating the positive rail 1-1 and the negative rail 1-2. , the positive pole track 1-1, the negative pole track 1-2, the insulating tape A1-3, and the insulating tape B1-4 are fixed by p...

Embodiment 2

[0031] In this embodiment, an explosive acceleration device is designed to meet the acceleration of 50m / s-200m / s for 10g of explosive.

[0032] An explosive acceleration device, characterized in that: the device includes a guide rail 1, a slider 2, a housing 3, explosives 4 and a turning tool 5, the guide rail 1 is made of conductive metal, and the cross section of the guide rail 1 is circular , the guide rail 1 is composed of a positive rail 1-1, a negative rail 1-2, an insulating tape A1-3, and an insulating tape B1-4, and the positive rail 1-1, the negative rail 1-2, and the insulating tape A1-3 1. The cross section of the guide rail 1 is divided into four parts by the insulating tape B1-4. The insulating tape A1-3 and the insulating tape B1-4 serve the dual purpose of observing the window and isolating the positive rail 1-1 and the negative rail 1-2. , the positive pole track 1-1, the negative pole track 1-2, the insulating tape A1-3, and the insulating tape B1-4 are fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com