Superhard polarizing lens

A polarized lens and lens technology, applied in the field of polarized lenses, can solve the problems that polarized lenses cannot meet the requirements of use, the fixing effect of polarized lenses is not good, and polarized lenses are easy to be stained with dust, etc., so as to achieve good light transmission effect and reduce accidents. Likelihood, the effect of increasing the fixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

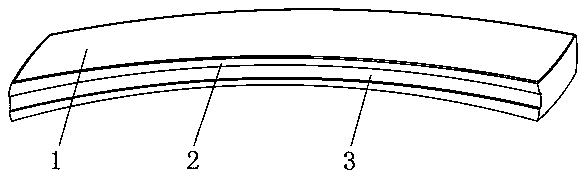

[0025] Such as Figure 1-3 As shown, a superhard polarizing lens includes a lens body 1, a TPU elastic light-transmitting ring 2 is fixedly installed around the lens body 1, and lens fixing grooves are provided on the front and rear outer surfaces of the TPU elastic light-transmitting ring 2 3. The outer surface of the TPU elastic light-transmitting ring 2 is provided with anti-skid lines, which can increase the friction around the lens.

[0026] The lens body 1 may be one of myopia lenses, hyperopia lenses and plain lenses.

[0027] The TPU elastic light-transmitting ring 2 is fixedly installed on the outside of the lens main body 1. The TPU elastic light-transmitting ring 2 has good elasticity. When the polarized lens falls on the ground, the lens is protected. The TPU elastic light-transmitting ring 2 will first contact the ground. Reduce the impact force between the polarized lens and the ground, and the light transmission effect of the TPU elastic light-transmitting ring...

Embodiment 2

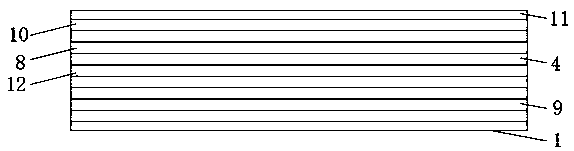

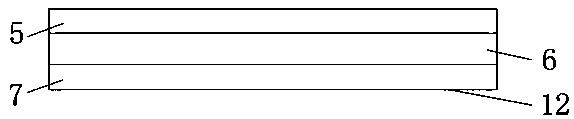

[0029] Such as Figure 1-3 As shown, a superhard polarizing lens, on the basis of Example 1, the lens main body 1 includes two layers of resin substrates 4, a hybrid film 12 is arranged between the two layers of resin substrates 4, and the hybrid film 12 includes a polarizing film 5 , the color-changing layer 6 and the anti-UV film 7, the color-changing layer 6 is located between the polarizing film 5 and the anti-UV film 7.

[0030] The outer surface of the resin substrate 4 away from the mixed film 12 is evenly covered with an AR composite anti-reflection film 8, and two sets of AR composite anti-reflection films 8 are pasted with an ITO antistatic film 9 on the outer surface of the resin substrate 4 away from the two groups. The outer surface of the ITO antistatic film 9 away from the two groups of AR composite antireflection films 8 is pasted with a hard film 10 .

[0031] The resin substrate 4 includes but not limited to polycarbonate substrate, CR-39 substrate and KR re...

Embodiment 3

[0034] Such as Figure 1-3 As shown, a superhard polarizing lens, on the basis of Example 2, two sets of hard films 10 are attached to the outer surfaces of two sets of ITO antistatic films 9 with nanometer super-hydrophobic films 11 .

[0035] Between the ITO antistatic film 9 and the AR composite anti-reflection film 8, between the ITO antistatic film 9 and the hard film 10, and between the hard film 10 and the nanometer super-hydrophobic film 11, UV adhesives are used for pasting.

[0036] The nano-superhydrophobic film 11 is arranged on the surface of the polarizing lens. The nano-superhydrophobic film 11 has a tighter molecular structure, and the hydrophobicity of the surface of the film layer is better. In the process of people's outdoor sports, there are accidents caused by dust attached to the polarized lens that affect people's vision, reducing the possibility of accidents, and the structure of the entire polarized lens is simple, and the use effect is better than tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com