Ballistic trajectory performance prediction software system in solid engine

A solid engine and software system technology, applied in computer-aided design, special data processing applications, instruments, etc., can solve problems such as cumbersome calculations, restricting engine design efficiency and design level, unfavorable engine performance rapid prediction and accurate prediction, etc., to achieve Strong calculation functions, improved design efficiency and design level, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

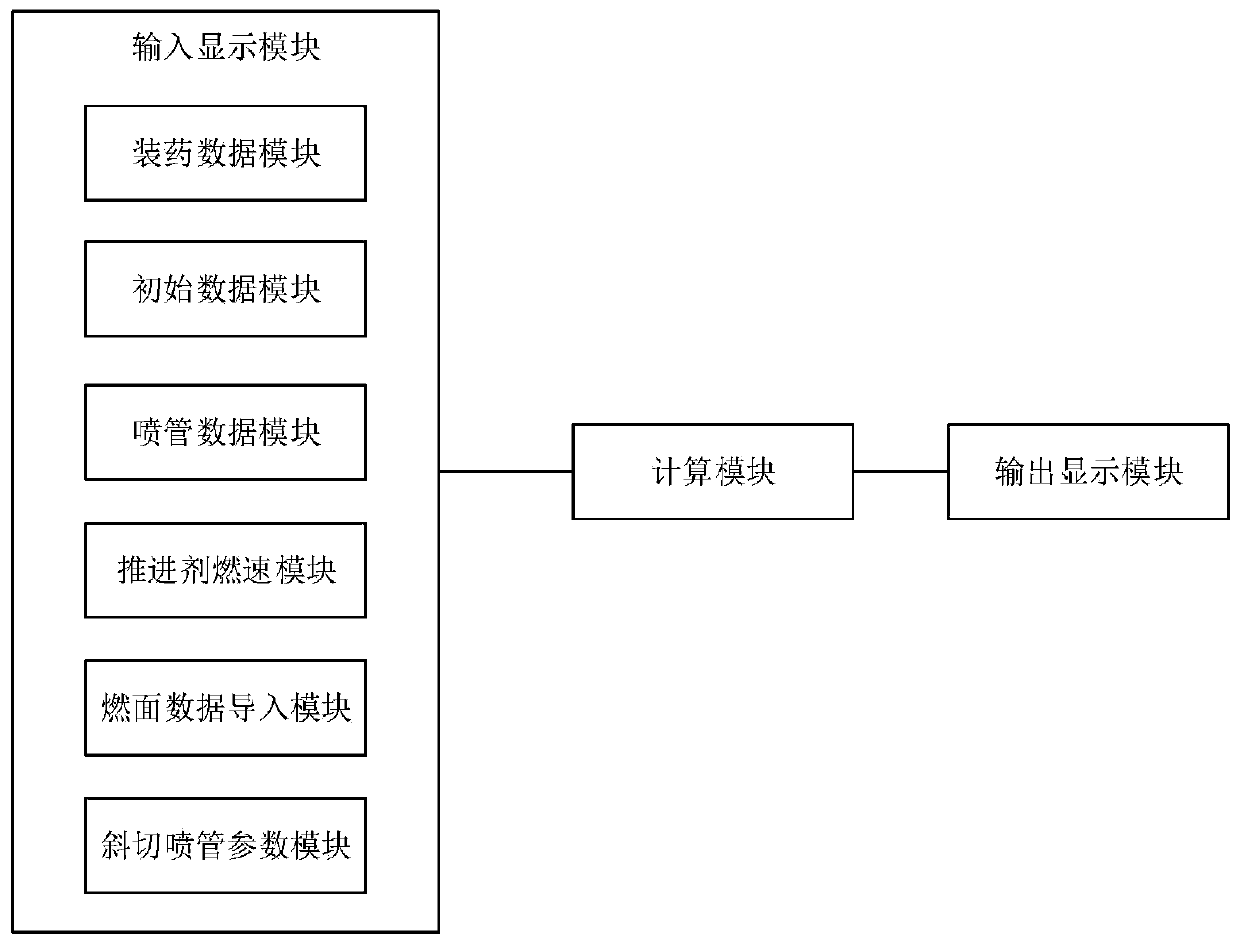

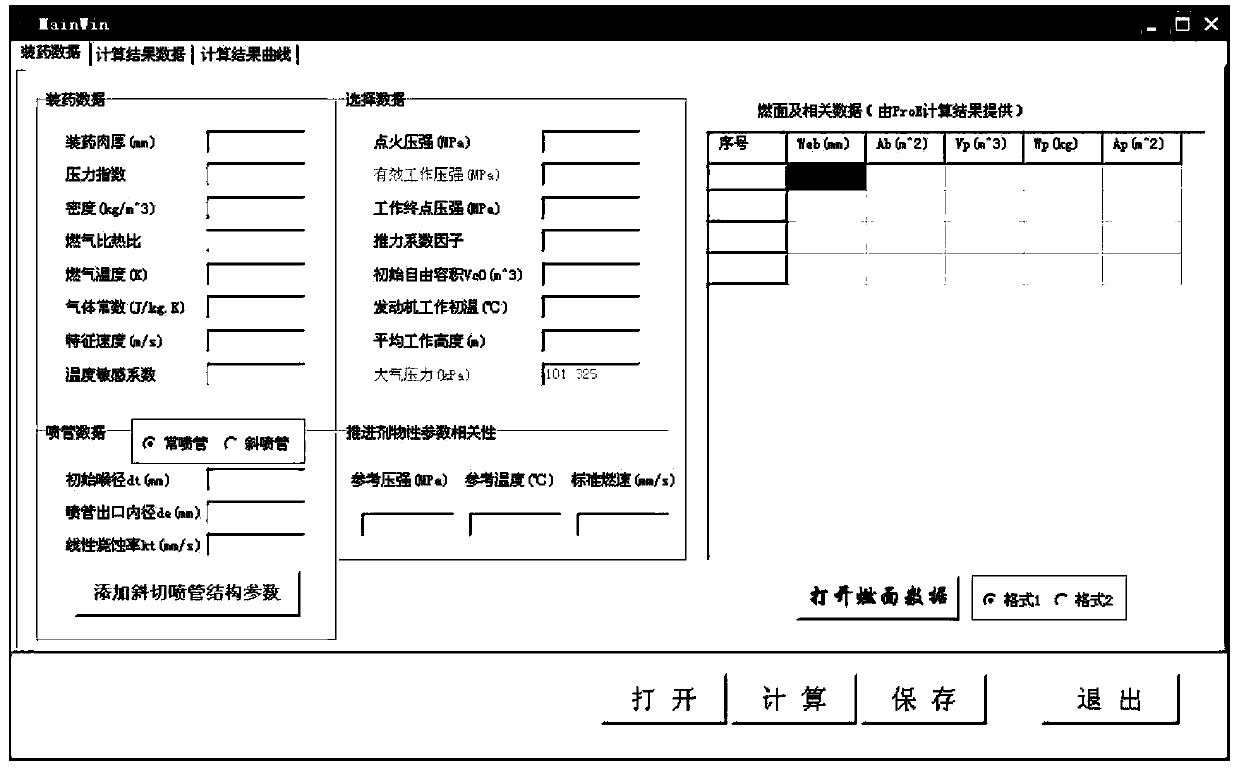

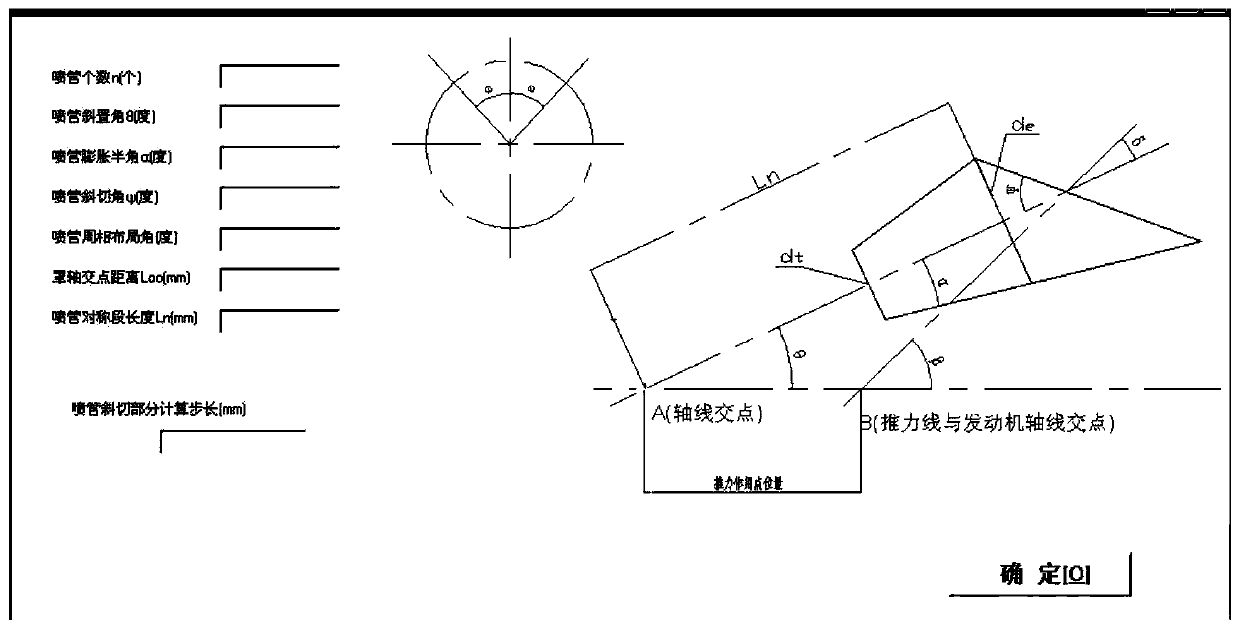

[0032] see figure 1 As shown, the embodiment of the present invention provides a ballistic performance prediction software system in a solid engine, which includes an input display module, a calculation module and an output display module; wherein, the input display module is used to display the input interface for inputting engine parameters, and the input interface It is used for the user to input engine parameters, including charge parameters, initial parameters of the engine’s working environment, conventional parameters of the nozzle, nozzle type, propellant burning rate parameters, data on the thickness retreat of the burning surface of the charge and oblique cutting Nozzle design parameters; nozzle types include conventional nozzles and beveled nozzles, design parameters include nozzle number, nozzle oblique angle, nozzle expansion half...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com