A display panel, its drive control method, and display device

A technology for display panels and screens, applied in static indicators, instruments, semiconductor devices, etc., can solve problems such as poor crosstalk, pixel crosstalk, and reduced display performance of display panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

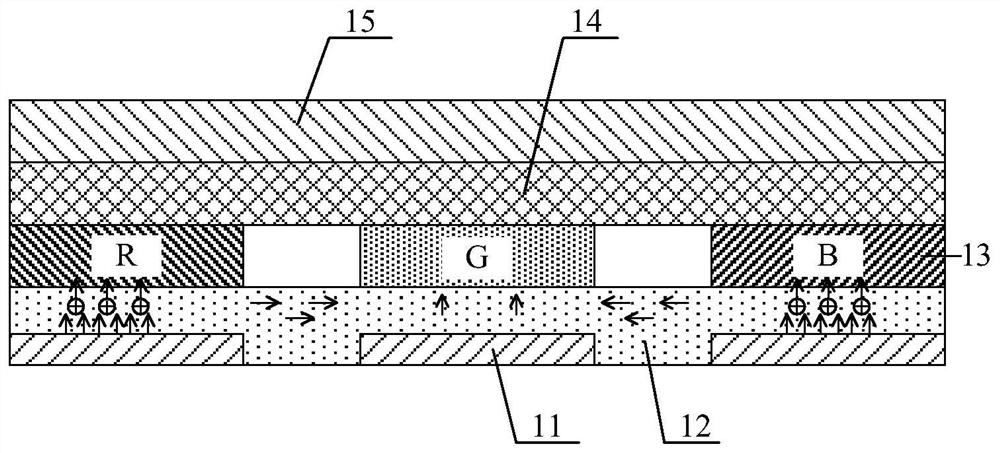

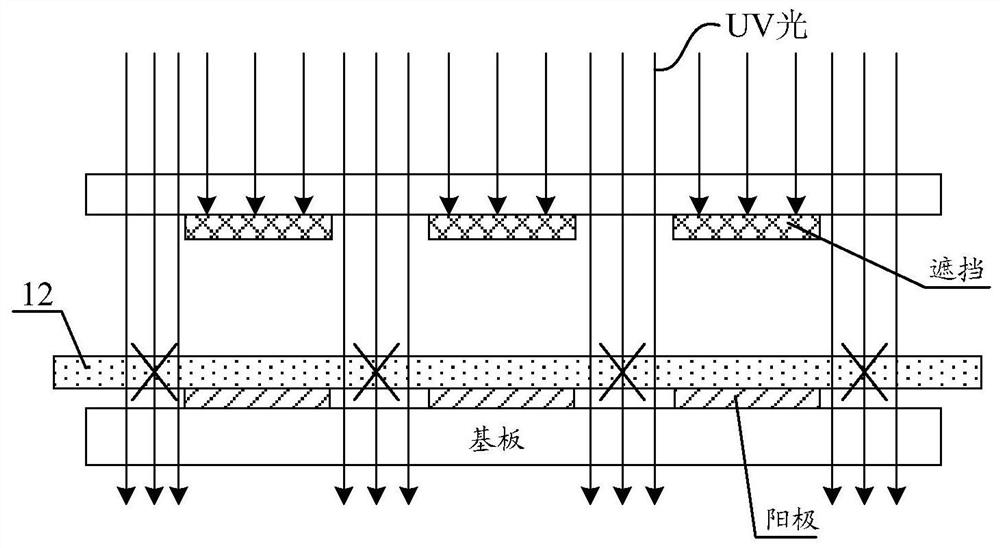

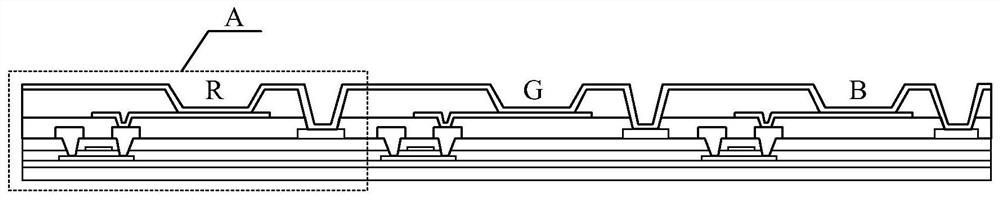

[0075] The embodiment of the present invention also provides a method for manufacturing a display panel, the display panel includes a plurality of OLED pixel regions, and the method includes:

[0076] S1: forming a first electrode and a third electrode located between two adjacent OLED pixel regions on the substrate;

[0077] S2: forming a hole injection layer on the first electrode and the third electrode;

[0078] S3: forming a light-emitting layer located in the OLED pixel region on the hole injection layer;

[0079] S4: forming an electron transport layer on the light-emitting layer;

[0080] S5: forming a second electrode on the electron transport layer.

[0081] The third electrode forms an electric field with the second electrode.

[0082] In one embodiment, the third electrode and the second electrode form a reverse electric field, and the reverse electric field is an electric field opposite to the direction of the electric field between the first electrode and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com