Temperature control device for lacquer-tree fruit peeling

A technology of a temperature control device and a conveying device, which is applied in the directions of shelling, application, and pod removal, can solve problems such as poor shelling effect, and achieve the effects of ensuring separation of skin and core, reducing cost, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

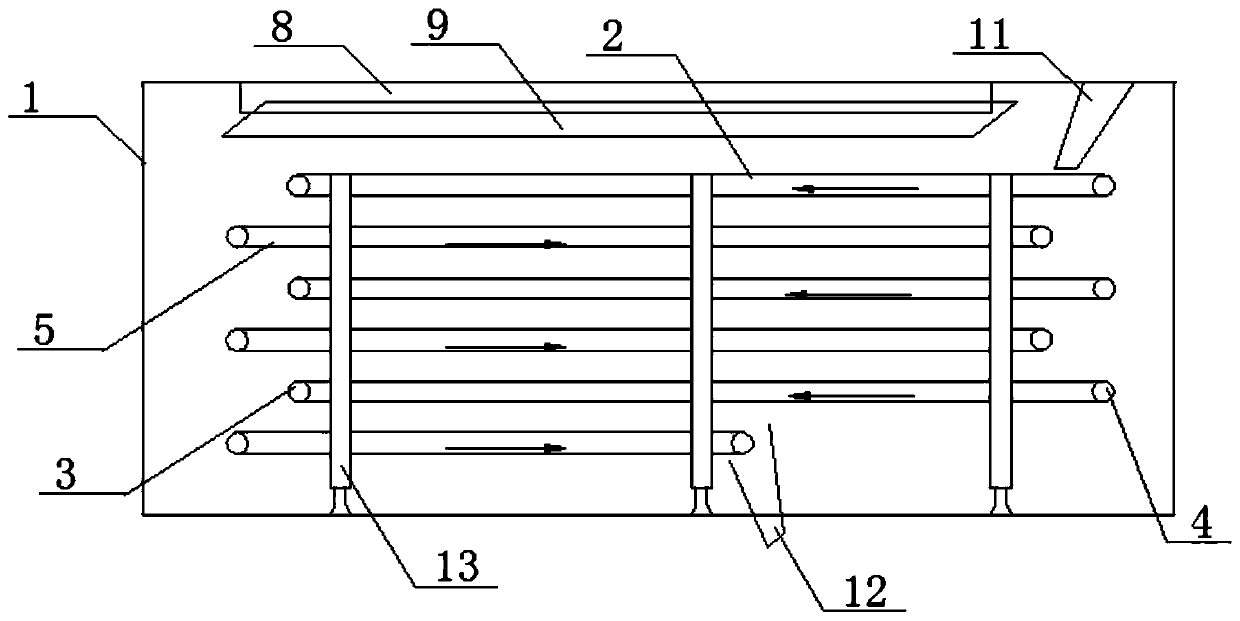

[0029] see figure 1 and 2 As shown, the temperature control device for peeling lacquer fruit of the present invention includes a heat preservation room 1, a multi-layer turning and reciprocating conveying device 2 and an air cooling device;

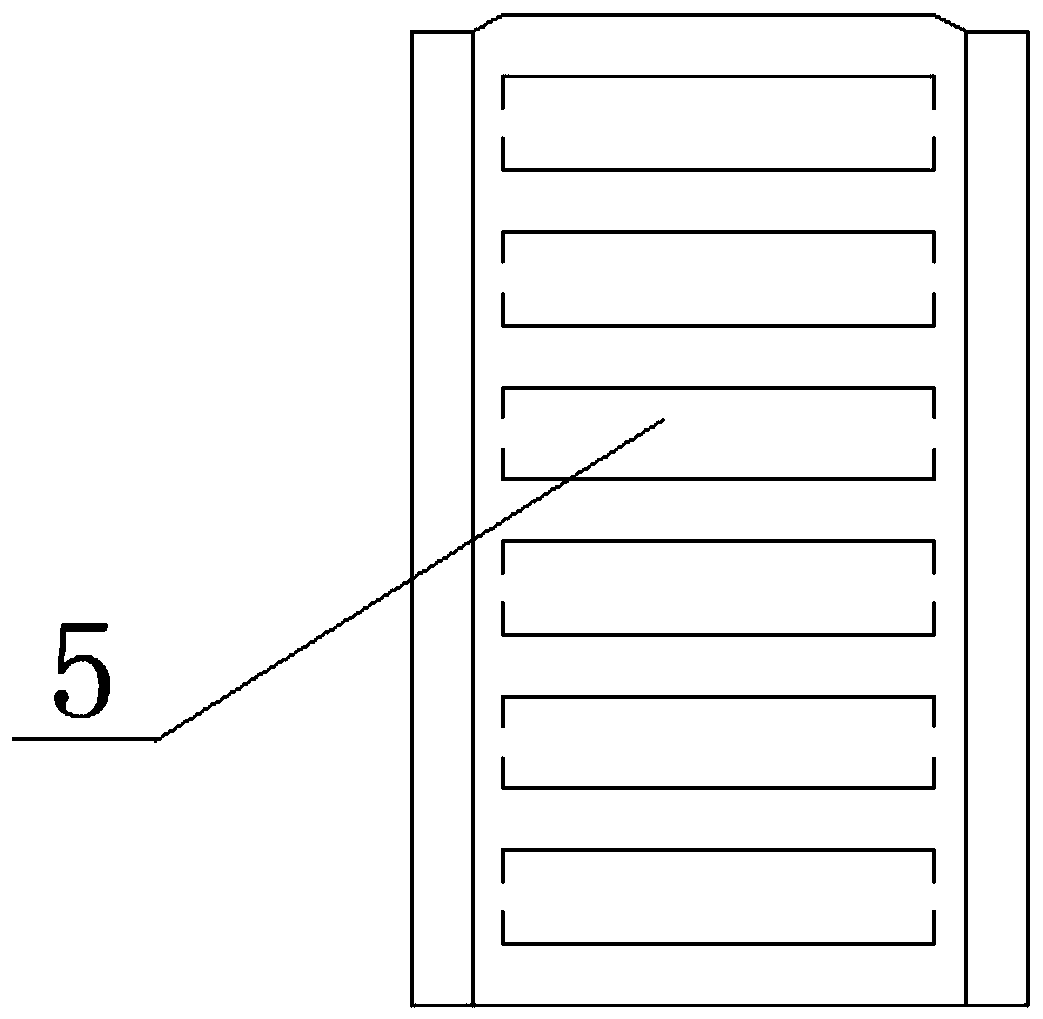

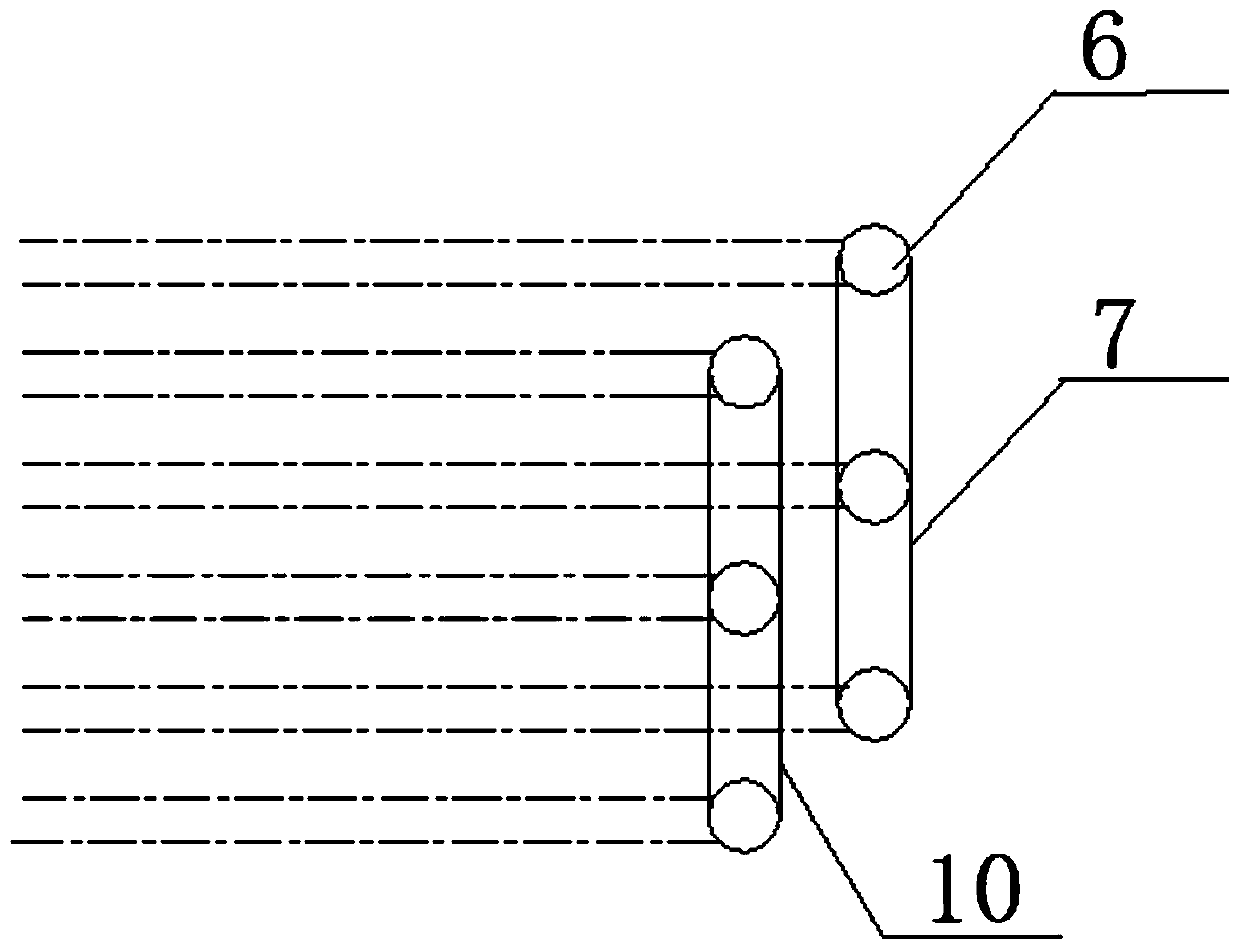

[0030] The multi-layer turning and reciprocating conveying device 2 is arranged in the heat preservation room 1, which includes a multi-layer conveyor belt 5, a first chain 7, a second chain and a motor 10;

[0031] The multi-layer conveyor belt 5 is a screen-type conveyor belt. The running directions of the upper and lower adjacent two-layer conveyor belts are opposite, and the lower-layer conveyor belt is protrudingly arranged along the running direction of the adjacent upper-layer conveyor belt, so as to ensure that the lacquer fruit falls naturally from the end of the upper-layer conveyor belt to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com