Aluminum-plastic composite film for energy storage power battery and preparation method thereof

A technology of aluminum-plastic composite film and power battery, which is applied to battery components, chemical instruments and methods, circuits, etc., can solve the problems of poor elongation performance, poor barrier performance and poor corrosion resistance of aluminum-plastic composite film, and achieve Improved elongation and corrosion resistance, increased adhesion, and increased adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

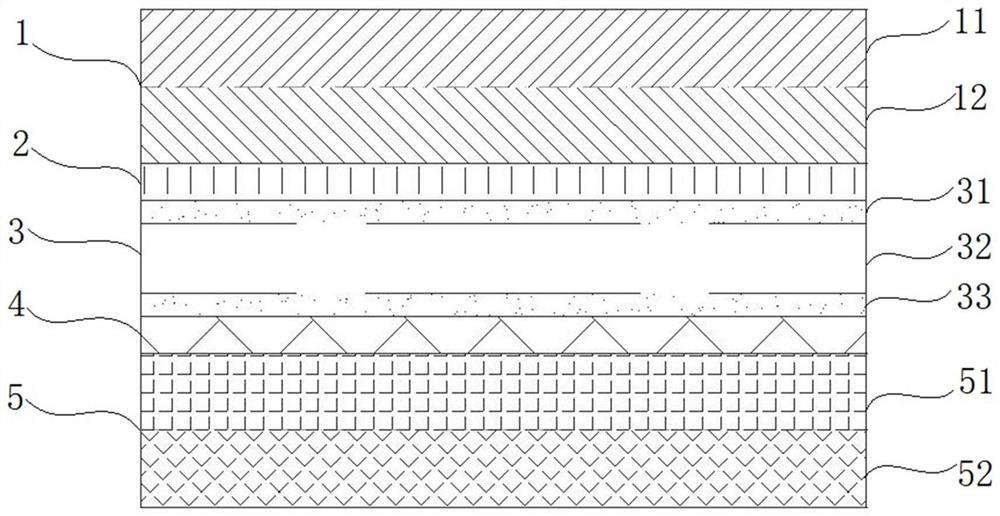

[0041] Main raw materials of polyester film and polyamide film: polyethylene terephthalate (Suzhou Zongda Plastic Raw Material Co., Ltd.), polyamide 66 resin (Shenzhen Plastic Crown Technology Co., Ltd.), SiO 2 Nano-modified particles and other additives are stirred and blended at room temperature according to the ratio of 1:1:0.1:0.1, and double-layer co-extruded to obtain a 40 μm thick anti-corrosion and heat-insulating outer layer; isocyanate: polyurethane elastomer: rosin modified resin: Other additives were stirred at 100°C for 1 hour according to the ratio of 8:1:0.5:0.1 to obtain a modified high and low temperature resistant outer layer adhesive; the surface of 30 μm thick aluminum foil was treated to obtain an environmentally friendly plasma passivated aluminum foil layer; precision coating Coating 3μm thick modified high and low temperature resistant outer layer adhesive on the outer layer of the environmentally friendly plasma passivated aluminum foil layer by way of ...

Embodiment 2

[0043] Main raw materials of polyester film and polyamide film: polyethylene terephthalate, polyamide 66 resin, SiO 2 Nano-modified particles and other additives are stirred and blended at 100°C in a ratio of 1:1:0.8:0.5, and double-layer co-extruded to obtain a 40 μm thick anti-corrosion and heat-insulating outer layer; isocyanate: polyurethane elastomer: rosin modified resin : Other additives were stirred at 180°C for 4 hours according to the ratio of 8:8:1:5 to obtain a modified high and low temperature resistant outer layer adhesive; the surface of 30μm thick aluminum foil was treated to obtain an environmentally friendly plasma passivated aluminum foil layer; Coating method Coating 3μm thick modified high and low temperature resistant outer layer adhesive on the outer layer of the environmentally friendly plasma passivation aluminum foil layer, and compounding with the outer layer of anti-corrosion and heat insulation protection; polyolefin main agent: melamine phosphate: ...

Embodiment 3

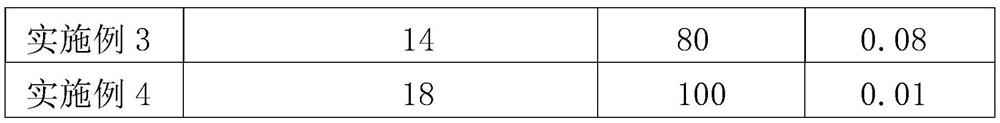

[0045] Main raw materials of polyester film and polyamide film: polyethylene terephthalate, polyamide 66 resin, SiO 2 Nano-modified particles and other additives are stirred and blended at 100°C in a ratio of 1:1:1:1, and double-layer co-extruded to obtain a 40 μm thick anti-corrosion and heat-insulating outer layer; isocyanate: polyurethane elastomer: rosin modified resin : Other additives were stirred at 180°C for 4 hours according to the ratio of 8:10:4:5 to obtain a modified high and low temperature resistant outer layer adhesive; the surface of 30μm thick aluminum foil was treated to obtain an environmentally friendly plasma passivated aluminum foil layer; Coating method Coating 3μm thick modified high and low temperature resistant outer layer adhesive on the outer layer of the environmentally friendly plasma passivation aluminum foil layer, and compounding with the outer layer of anti-corrosion and heat insulation protection; polyolefin main agent: melamine phosphate: add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com