Method for preparing iron-based amorphous alloy strip by reducing casting temperature of melt

An iron-based amorphous alloy and pouring temperature technology is applied in the field of reducing the melt pouring temperature to prepare iron-based amorphous alloy strips. High reproducibility and repeatability, low cost and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

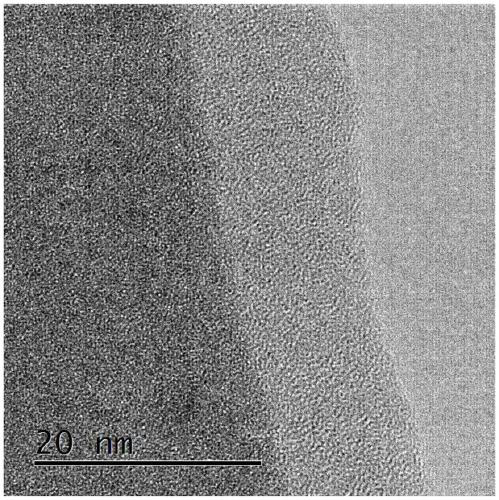

[0034] to adopt Fe 76 PCSi 6 B 16 Take the amorphous alloy thin strip as an example, the number in the chemical formula is at%, and the amorphous solid alloy thin strip is prepared by the high-speed planar flow continuous casting method commonly used in this field. The specific operation steps of the process method for preparing iron-based amorphous alloy strips by using a kind of method proposed by the present invention to reduce the melt pouring temperature are as follows:

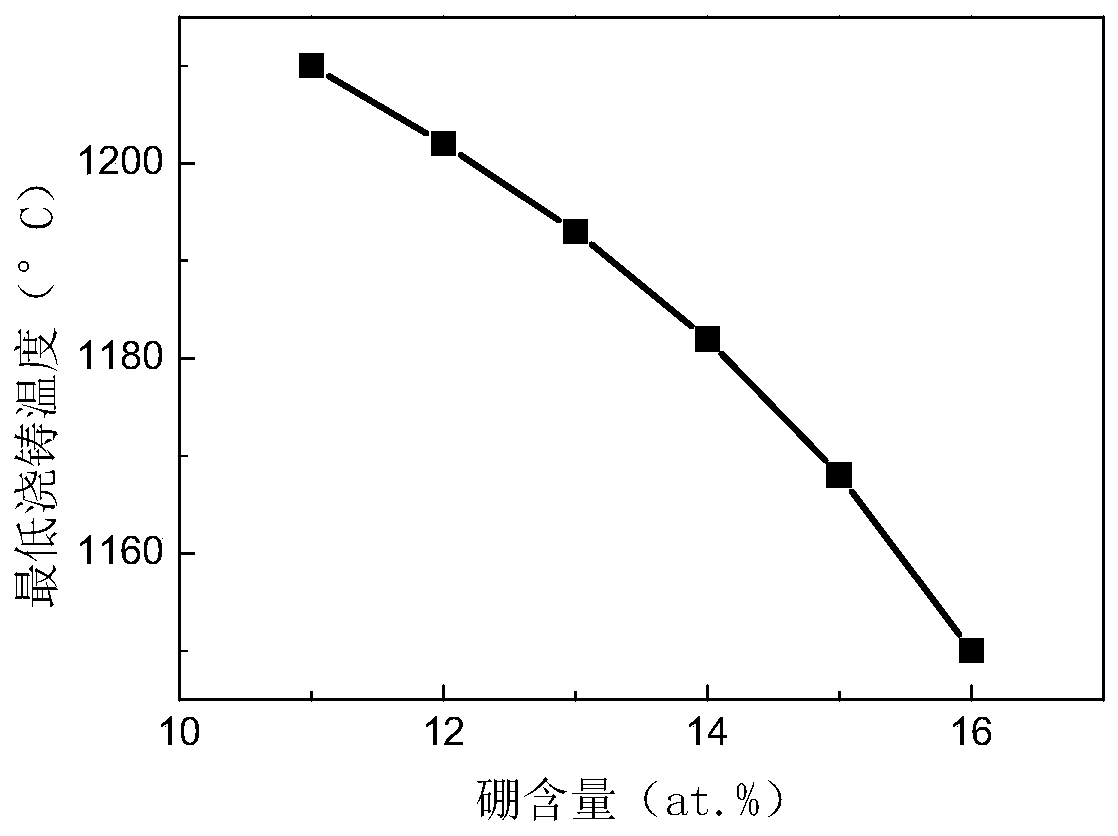

[0035] Step 1, establish the minimum casting temperature of different composition amorphous alloy melts: (1) prepare 6 kinds of different nonmetal element compositions Fe 76 PCSi 22-X B X alloy melt, where the value of X ranges from 11 to 16, and the step size of each change of X is 1; (2) from Fe 76 PCSi 22-X B X The normal casting temperature of the melt starts at 1260°C, and the range of reducing the casting temperature is set to 10°C each time. The method of lowering the casting temperature is...

Embodiment 2

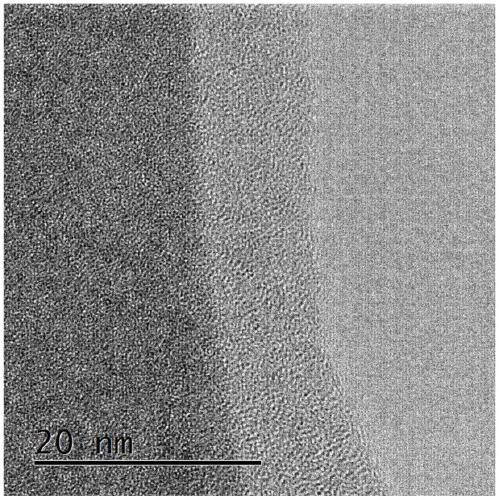

[0041] to adopt Fe 76 PCSi 11 B 11 Take the amorphous alloy thin strip as an example, the number in the chemical formula is at%, and the amorphous solid alloy thin strip is prepared by the high-speed planar flow continuous casting method commonly used in this field. The specific operation steps of the method for preparing iron-based amorphous alloy strips by using a method of reducing the melt pouring temperature proposed by the present invention are as follows:

[0042] Step 1, establish the minimum casting temperature of different composition amorphous alloy melts: (1) prepare 6 kinds of different nonmetal element compositions Fe 76 PCSi 22-X B X alloy melt, where the value of X ranges from 9 to 21, and the step size of each change of X is 1; (2) from Fe 76 PCSi 22-X B XThe normal casting temperature of the melt starts at 1260°C, and the range of reducing the casting temperature is set to 10°C each time. By lowering the casting temperature, a series of alloy melts wit...

Embodiment 3

[0048] to adopt Fe 76 PCSi 9 B 13 Take the amorphous alloy thin strip as an example, the number in the chemical formula is at%, and the amorphous solid alloy thin strip is prepared by the high-speed planar flow continuous casting method commonly used in this field. The specific operation steps of the method for preparing iron-based amorphous alloy strips by using a method of reducing the melt pouring temperature proposed by the present invention are as follows:

[0049] Step 1, establish the minimum casting temperature of different composition amorphous alloy melts: (1) prepare 6 kinds of different nonmetal element compositions Fe 76 PCSi 22-X B X alloy melt, where the value of X ranges from 9 to 21, and the step size of each change of X is 1; (2) from Fe 76 PCSi 22-X B X The normal casting temperature of the melt starts at 1260°C, and the range of reducing the casting temperature is set to 10°C each time. By lowering the casting temperature, a series of alloy melts wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com