Spot plating device and spot plating production line

A technology of spot plating and plating solution, applied in the direction of electrolysis process, electrolysis components, etc., can solve the problems of increased production cost, increased processing procedures, material waste, etc., and achieve the effect of improving accuracy, reducing procedures, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

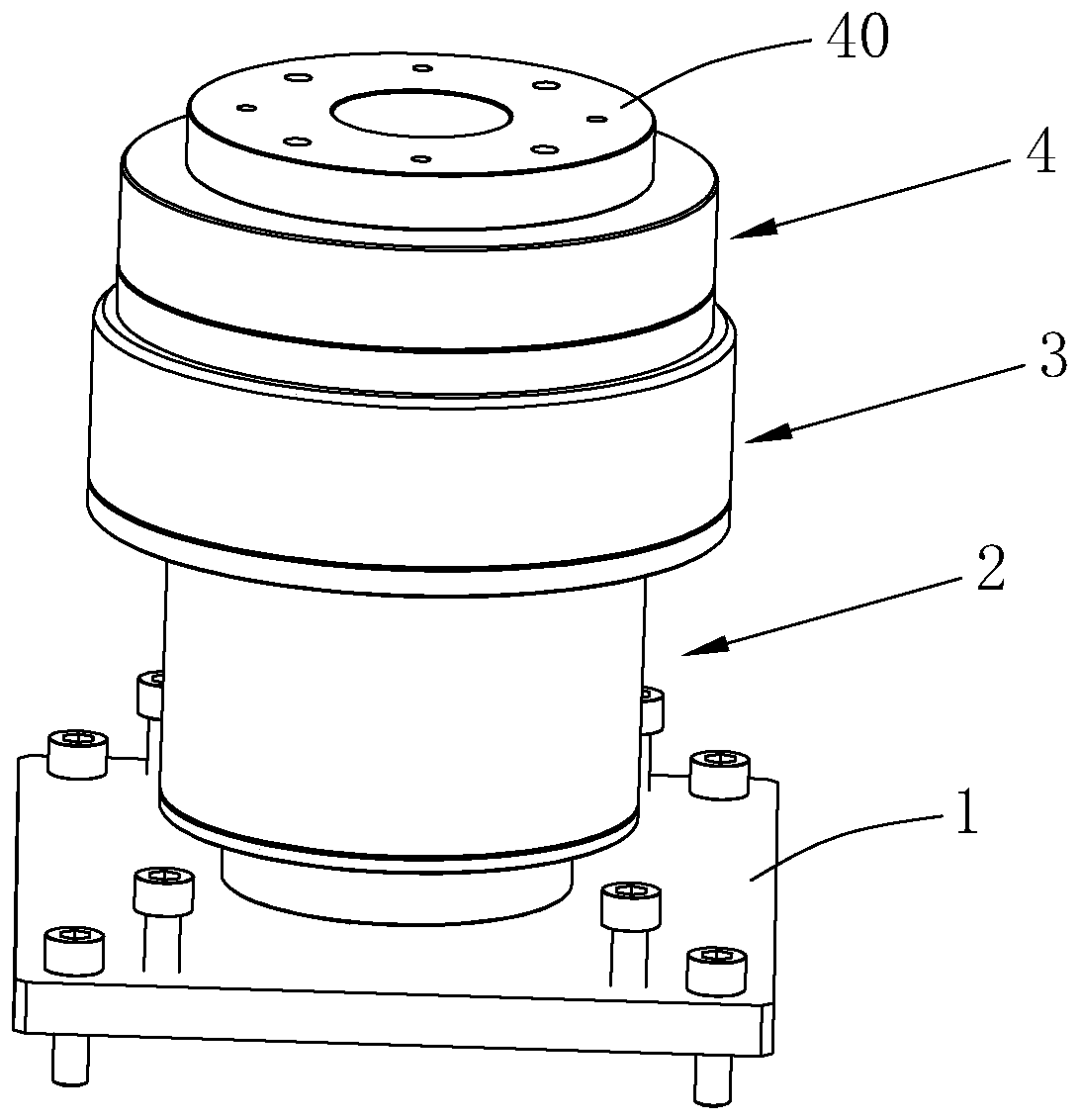

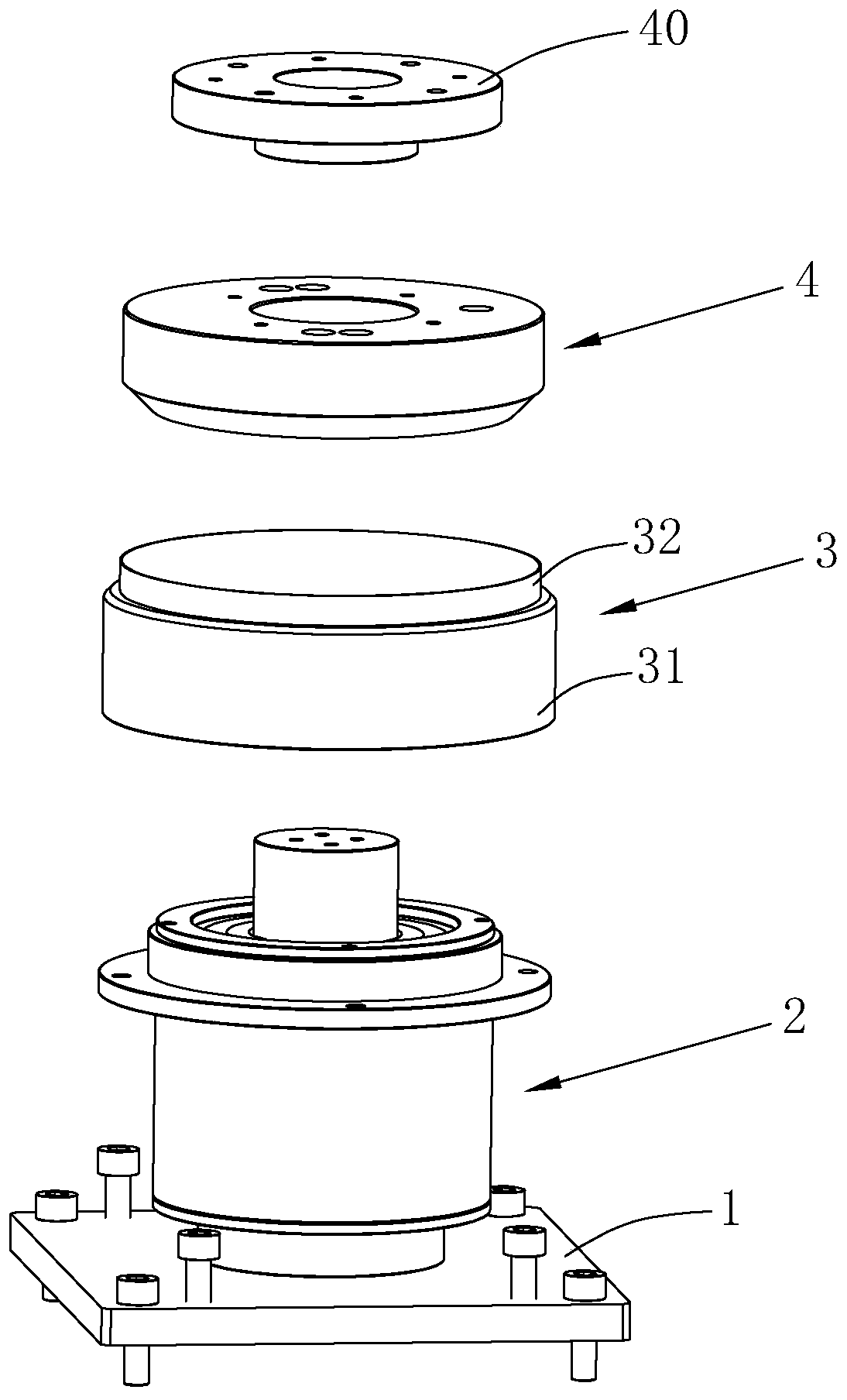

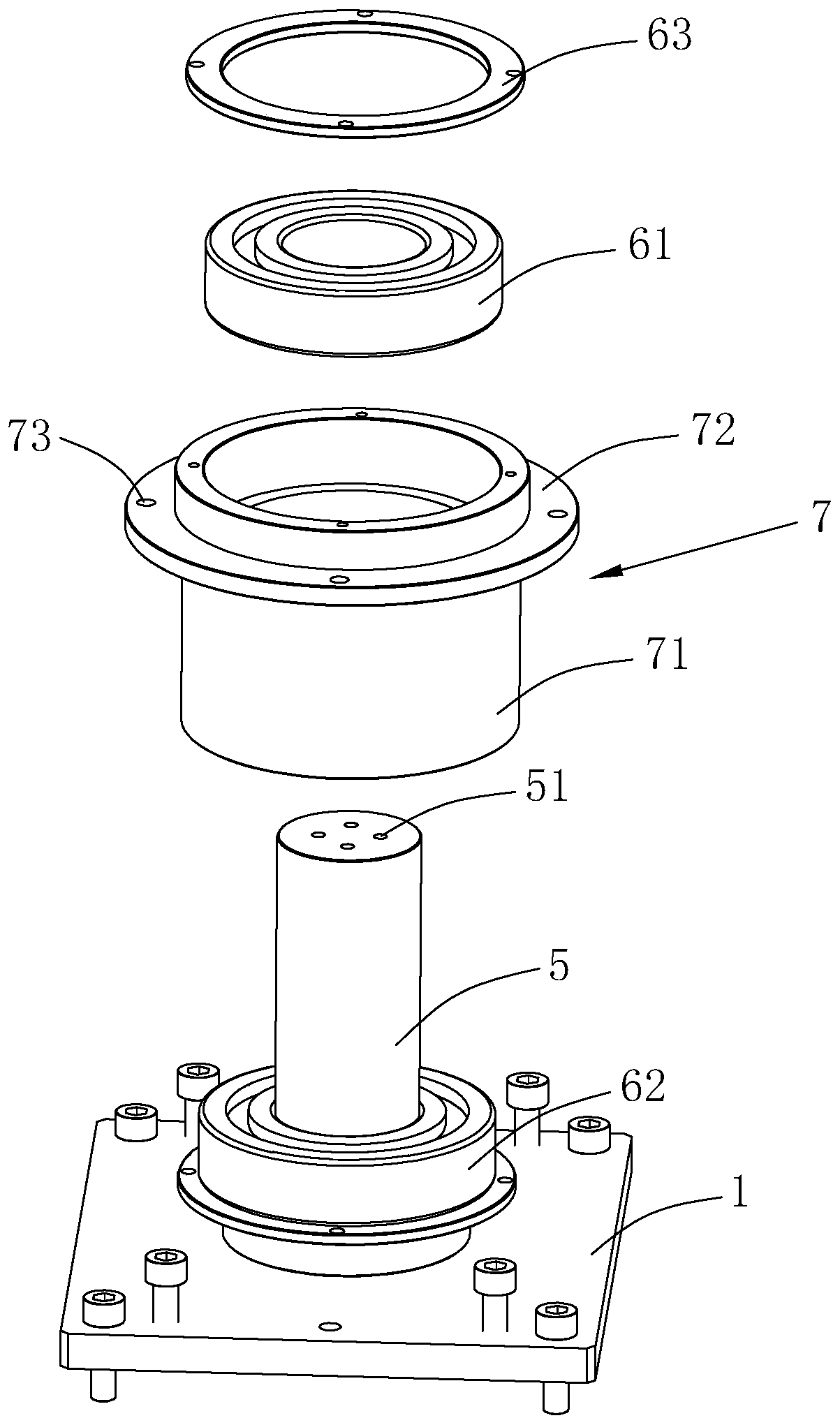

[0052] A spot plating device, with reference to figure 1 and figure 2 , including a rotating mechanism 2, a spot plating wheel 3, a spot plating electrode module 4 and a sealing cover 40.

[0053]Among them, the rotating mechanism 2 is used to support the spot plating wheel 3 to rotate, and is used to fix the spot plating electrode module 4. The spot plating wheel 3 winds the material tape and rotates with the material tape to limit the material tape to the position where spot plating is required. . The sealing cover 40 is used to seal the spot plating electrode module 4 and inject plating solution into the spot plating electrode module 4 . When the electroplating electrode module is continuously spraying, the spot plating wheel 3 drives the material strip to continue to be transported forward, and the next required spot plating position of the material strip is switched along with the electroplating spraying for spraying.

[0054] refer to figure 2 , The spot plating wh...

Embodiment 2

[0072] A spot plating production line, with reference to Figure 7 and Figure 8 , including the spot plating device as in Embodiment 1, and also includes a spot plating support mechanism 8 for conveying the material belt to the spot plating device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com