Refilling gas storage type solid propellant power device

A solid propellant and power device technology, applied in jet propulsion devices, rocket engine devices, machines/engines, etc., can solve problems such as separation difficulties, achieve simple ignition methods, save structural materials, and have low strength design requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings and embodiments, so as to understand the purpose, features and effects of the present invention.

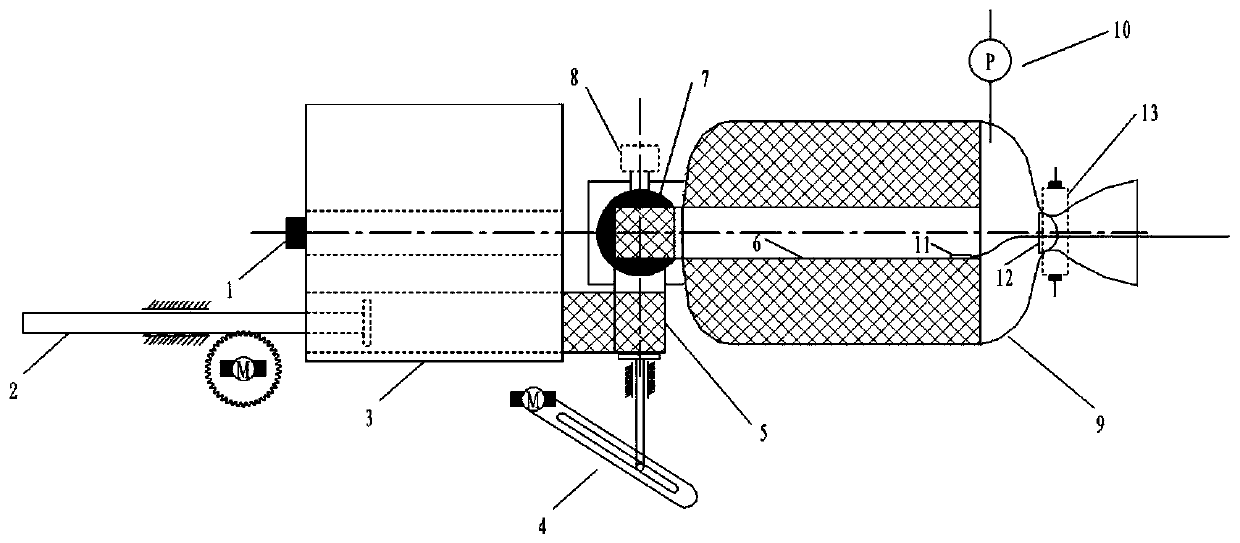

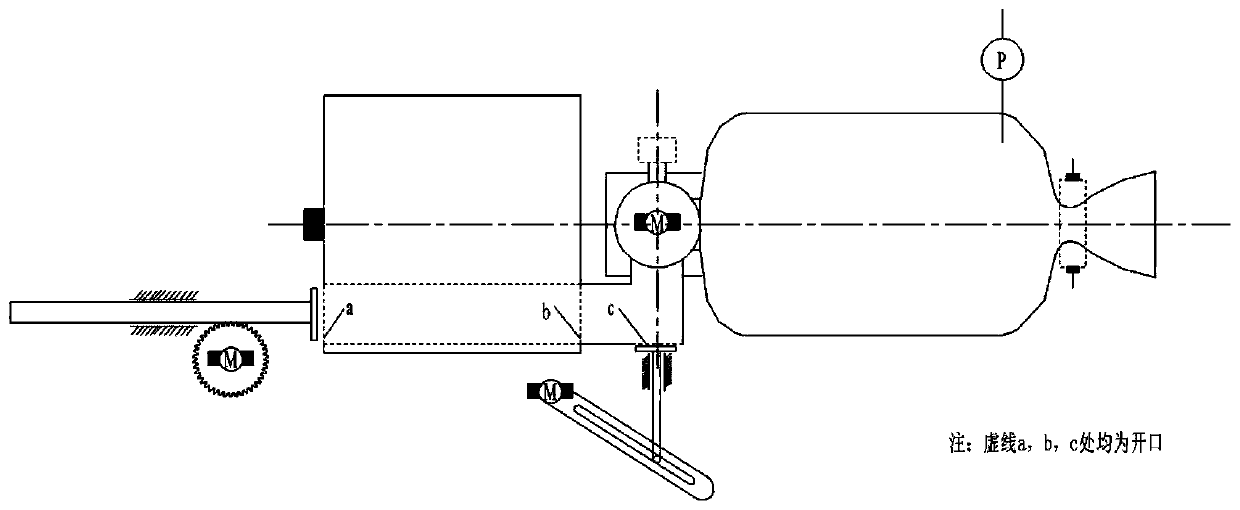

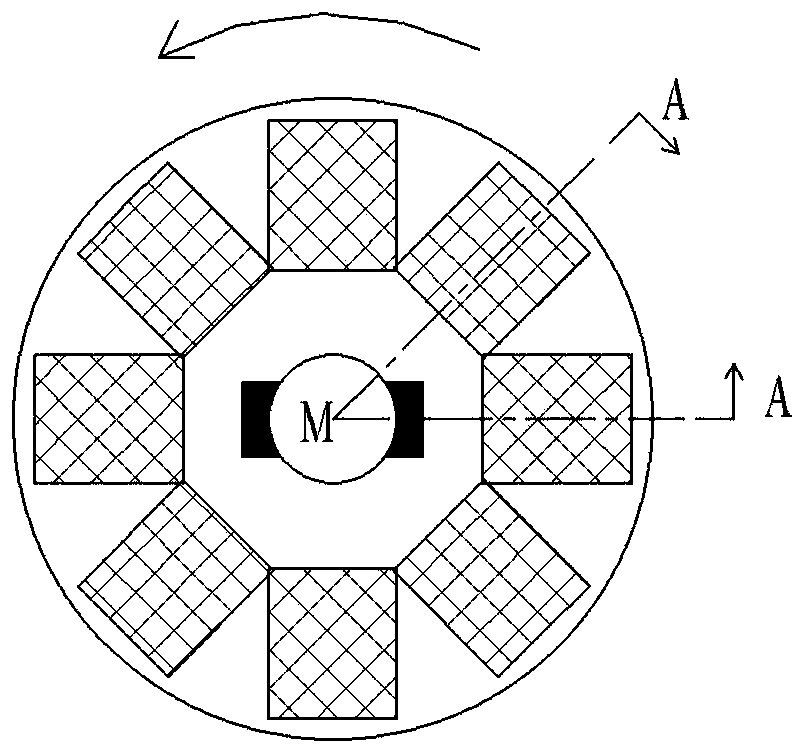

[0030] Such as figure 1 As shown, a reloaded gas-storage solid rocket motor includes: charge storage chamber rotating motor 1, first charge push rod 2, charge storage chamber 3, second charge push rod 4, pulse charge 5. Main charge 6, charge loader 7, residual gas release device 8, gas storage chamber 9, pressure measurement and control device 10, igniter 11, nozzle seal 12, valve control nozzle 13. The remaining gas release device 8 is connected to the charge loader 7 through a pipeline, the opening at the front head of the gas storage chamber 9 is connected to the charge loader 7 to form a closed space, and the tail is connected to the controllable nozzle 13 . The main charge 6 is designed as an internal combustion tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com