Dual-purpose insulation structure and die head threading machine comprising same

A technology of insulating structure and threading machine, which is applied in the direction of thread cutting machine, metal processing equipment, thread cutting device, etc., to achieve the effect of improved efficiency factor, low cost and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

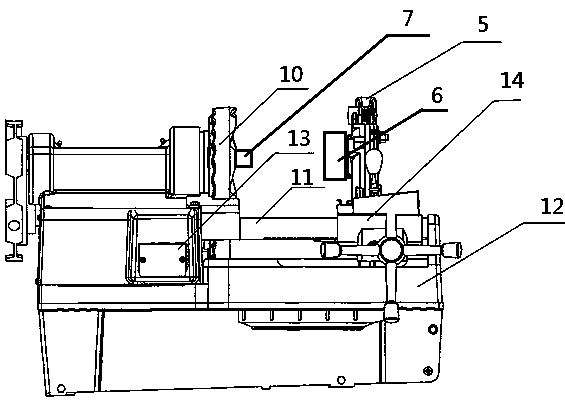

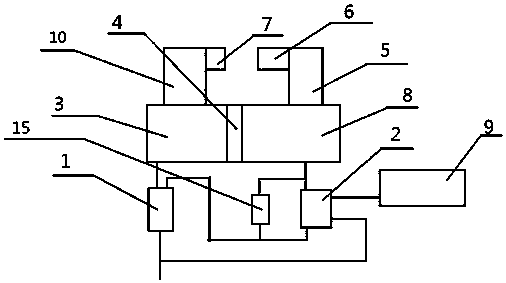

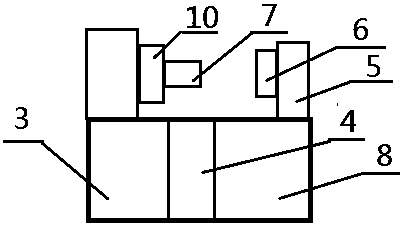

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

[0030] There is a conductive channel between the chuck and the tool holder of the mechanical body (threading machine) in the prior art, and the conductive channel is formed by the mechanical connection between the parts. Under the existing technology, the change of the conductive channel does not affect the mechanical body mechanical purpose.

[0031] see figure 1 As shown in -2, a dual-purpose insulation structure of the present invention includes a mechanical body and an insulating module. The mechanical body is separated into conductor A and conductor B through the insulation module. Conductor A and conductor B are two different conductive Body, the chuck and the tool holder of the mechanical body are arranged on the conductor A and the conductor B. The conductor A and the conductor B form a contact switch through the insulation module. During processing, the condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com