Dual-purpose control system and die head threading machine comprising same

A control system and threading machine technology, applied in the direction of thread trimmers, manufacturing tools, metal processing machinery parts, etc., can solve the problems of shortening no-load time, running stability, and unstable conductive transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

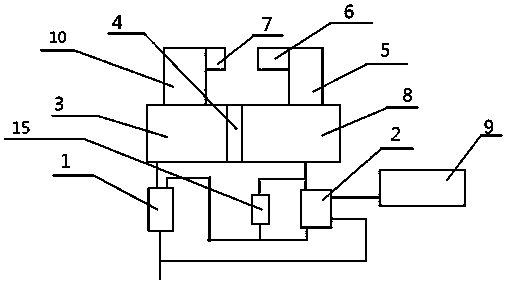

[0026] Example 1, see figure 1 As shown, a dual-purpose control system described in the present invention, a dual-purpose control system, includes a control system and a compensation module. The compensation module is connected to the charge and discharge of the control system. It is used for short-term stability of the control system by discharging when the current flow is unstable. The control system includes a transformer module, a control module, a mechanical body, and an insulation module. The mechanical body is separated into conductor A and conductor B by the insulation module. Conductor A is connected to the insulation module, and the insulation module is connected to the conductor B. Connected, the connection is the combination of insulating connection and mechanical connection, the conductor A and the conductor B are insulated and isolated; the conductor A and the conductor B are attached: the mechanical parts set by the mechanical body for the purpose of completing ...

Embodiment 2

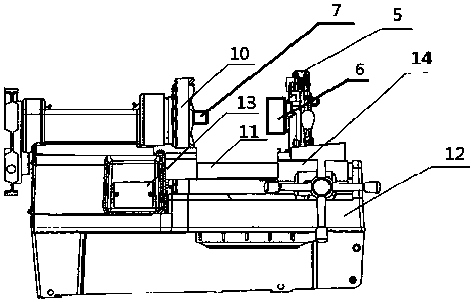

[0034] Example 2, see figure 1 -2 shows,

[0035]Further, a threading machine using a dual-purpose control system includes a motor and a dual-purpose control system. The dual-purpose control system includes a control system and a compensation module. The motor is connected to the control system and used to accept the control system. Control, the motor is connected to the mechanical body for power transmission; the mechanical body is separated into conductor A and conductor B by an insulating module, and the mechanical body includes a frame, a chuck, a slide rail, a carriage, a tool rack, and a frame The chuck is set as one conductor, the slide rail, carriage and tool rack are set as another conductor, and the conductors are separated by insulating modules. A deceleration transmission system is also installed in the frame, and a chuck is installed on the deceleration transmission system. , the chuck and the frame are mechanically connected with the conductor; the sliding sleev...

Embodiment 3

[0046] see figure 1 A dual-purpose control system shown includes a transformer module, a control module, a mechanical body, and an insulating module. The mechanical body is attached with mechanical parts for the purpose of completing the processing. The mechanical body is separated into conductive parts by the insulating module. Body A, conductor B, conductor A and conductor B are insulated and separated. The mechanical parts include parts for fixing workpieces and tools. The parts are respectively arranged on conductor A and conductor B. The parts It is a chuck and a tool holder; the conductor A is connected to the insulation module, the insulation module is connected to the conductor B, the output terminal of the transformation module is connected to the conductor A or the conductor B, and the remaining one is connected to the control module The control module is connected to the other output end of the transformer module, and the connection forms an open circuit. The contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com