Negative electrode sheet and lithium ion battery including negative electrode sheet

A technology of lithium ion battery and negative pole piece, applied in the direction of negative electrode, secondary battery, battery electrode, etc., can solve the problems of reducing electrolyte, piercing the separator, deteriorating the cycle life of lithium ion battery, etc., so as to reduce the charge transfer resistance. , to avoid the effect of lithium precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

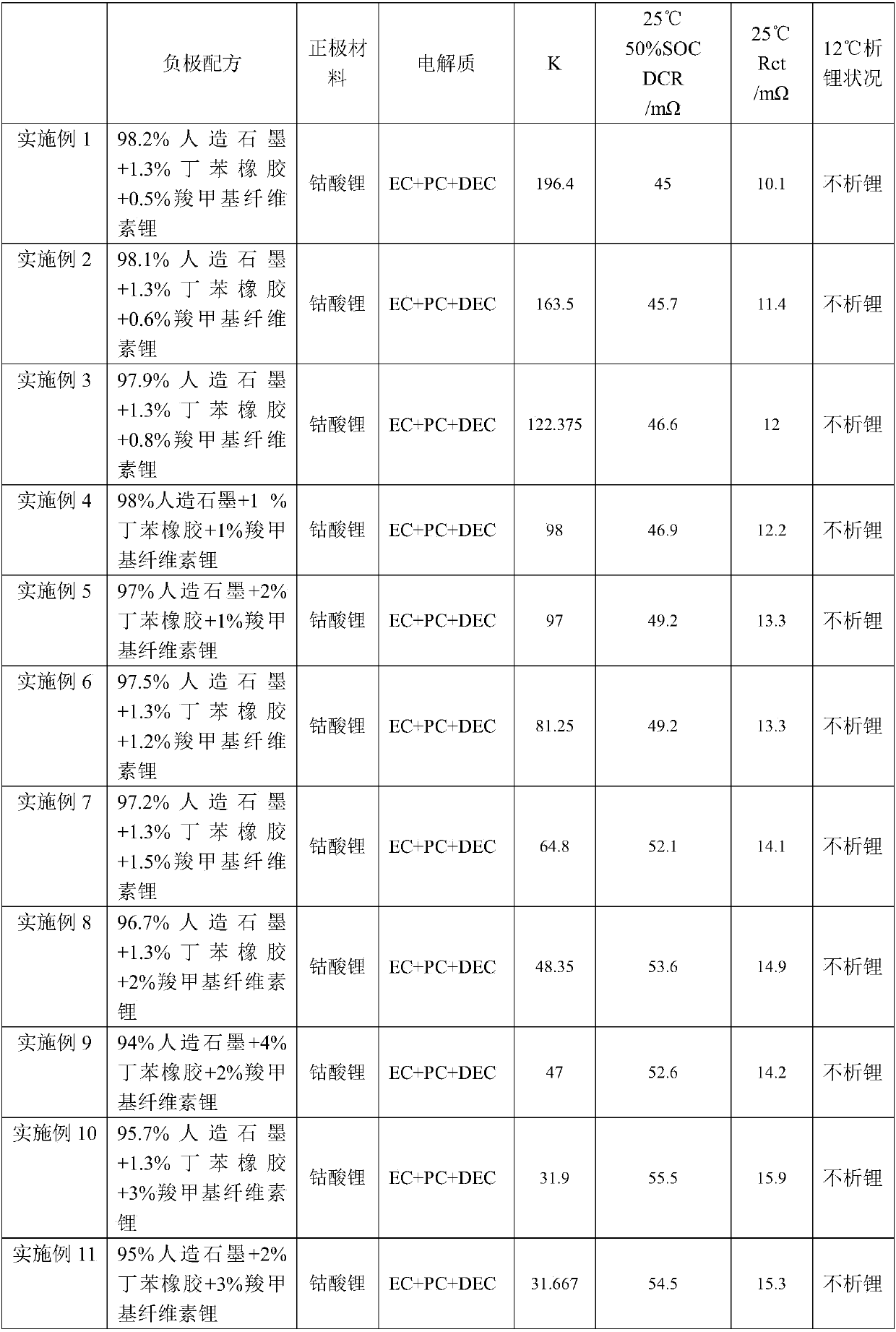

Embodiment 1

[0059] Consistent with the preparation method of Comparative Example 1, the difference is that the composition of the negative electrode active material layer slurry in Example 1 is a combination of 98.2wt% artificial graphite, 1.3wt% styrene-butadiene rubber and 0.5wt% carboxymethylcellulose lithium .

Embodiment 2

[0061] Consistent with the preparation method of Comparative Example 1, the difference is that the composition of the negative electrode active material layer slurry in Example 2 is a combination of 98.1wt% artificial graphite, 1.3wt% styrene-butadiene rubber and 0.6wt% lithium carboxymethyl cellulose .

Embodiment 3

[0063] Consistent with the preparation method of Comparative Example 1, the difference is that the composition of the negative electrode active material layer slurry in Example 3 is a combination of 97.9wt% artificial graphite, 1.3wt% styrene-butadiene rubber and 0.8wt% carboxymethylcellulose lithium .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com