Positive electrode and secondary battery

A positive electrode sheet and positive electrode film technology, which is applied in the field of positive electrode sheets and secondary batteries, can solve the problems of loss of positive electrode active material ratio, reduction of positive electrode active material content, and energy density reduction, so as to enhance electronic conductivity and adhesion , enhanced electronic conductivity, and improved safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

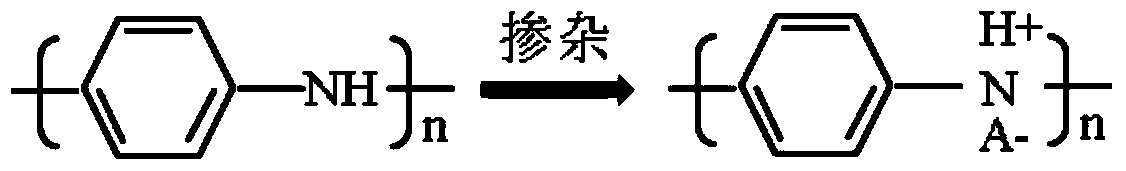

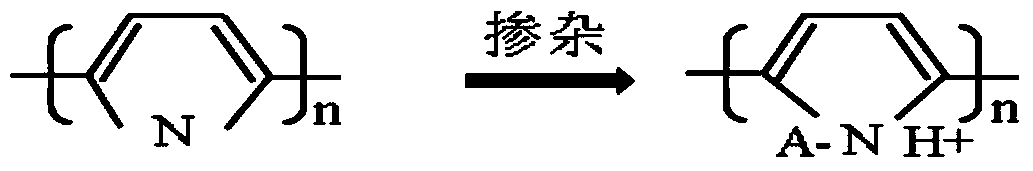

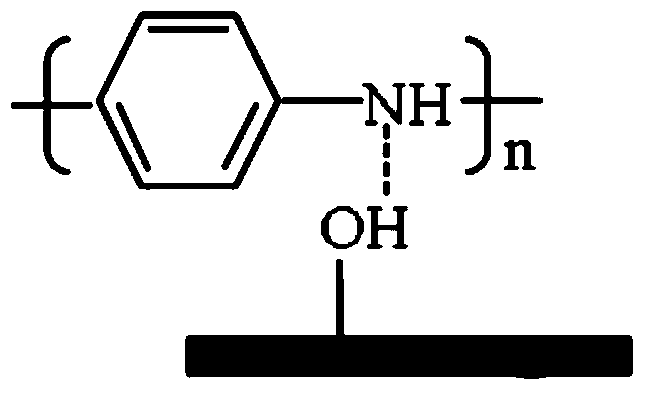

[0025] Next, the preparation method of the positive electrode sheet according to the second aspect of the present invention is described, which is used to prepare the positive electrode sheet of the first aspect of the present invention, comprising the steps of: (1) blending the conductive polymer material and the dopant by stirring and dispersing Obtain the undercoating slurry in a solvent, and then coat the undercoating slurry on the positive electrode current collector; (2) dissolve the positive electrode active material and the binder in the solvent to obtain the positive electrode slurry, and then apply the positive electrode slurry Coating on the undercoating slurry, followed by drying and compacting by a roller press to obtain a positive electrode sheet, wherein the undercoating slurry is dried to form an undercoat layer, and the positive electrode slurry is dried to form a positive electrode membrane.

[0026] During the drying process of the slurry, the nitrogen atom o...

Embodiment 1

[0033] Dissolve 99.0wt% polyaniline, 0.5wt% dodecylbenzenesulfonic acid and 0.5wt% sodium polyacrylate in N-methylpyrrolidone (NMP) and disperse and stir at a high speed to obtain the undercoating slurry, and the undercoating slurry The solid content of the material is about 7%, the viscosity is 300mPa.s, and then the undercoating slurry is coated on the aluminum foil, and the coating thickness is controlled to be 1 μm to 6 μm to obtain the substrate J1 containing the undercoating layer.

Embodiment 2

[0035] Dissolve 98.5wt% of polypyrrole, 1wt% of dodecylbenzenesulfonic acid and 0.5wt% of sodium polyacrylate in NMP, disperse and stir at a high speed to obtain a primer slurry, and the solid content of the primer slurry is about 10% , with a viscosity of 1800 mPa.s, and then coating the undercoating slurry on the aluminum foil, controlling the coating thickness to be 2 μm to 10 μm to obtain the substrate J2 containing the undercoating layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com