Plate heater

A heating element and plate-shaped technology, applied in the direction of electric heating devices, ohmic resistance heating, heating element materials, etc., can solve the problems of low heat generation, large current flow, uneven heating, etc., to improve applicability and uniform current flow , the effect of increasing heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

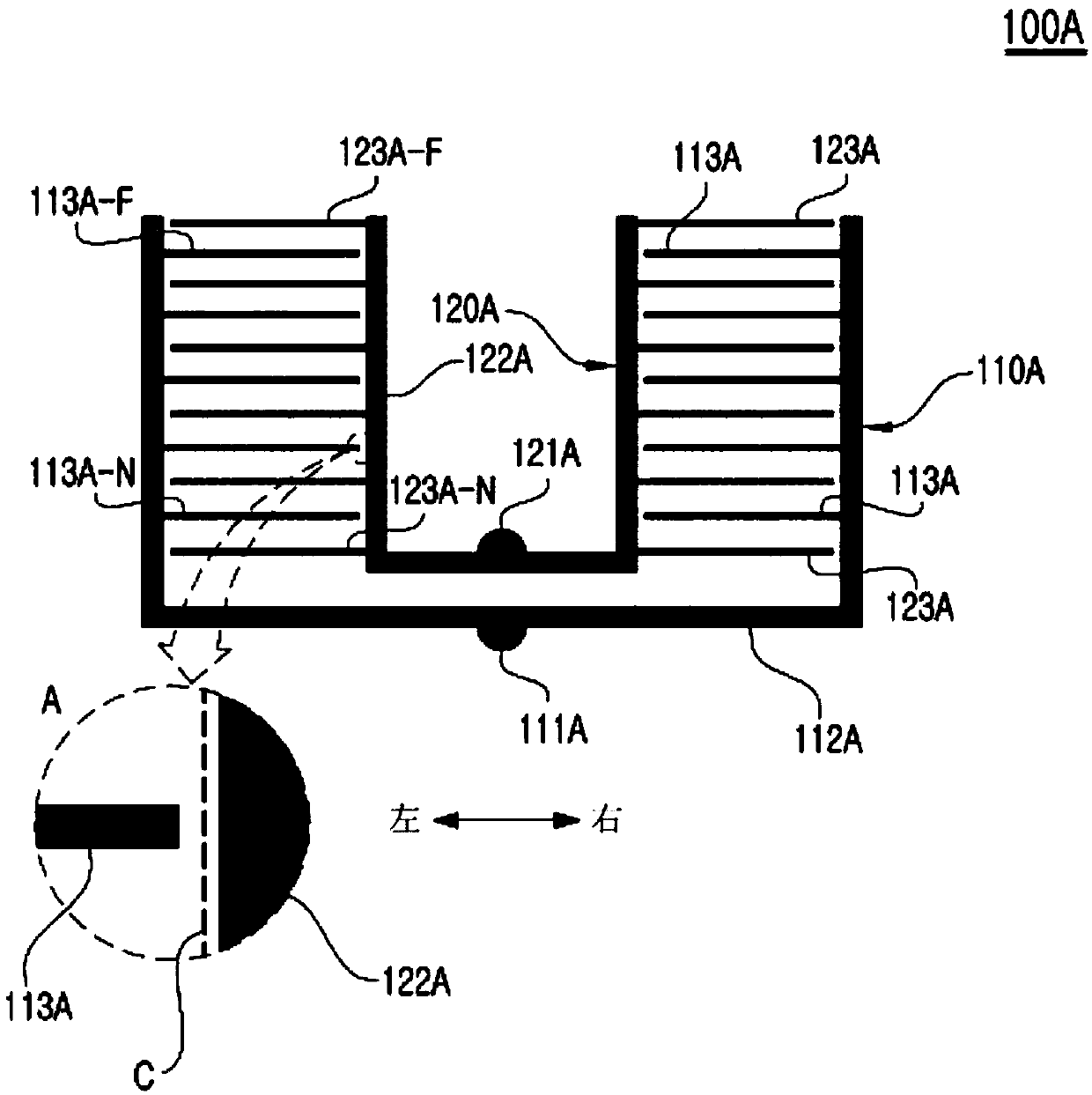

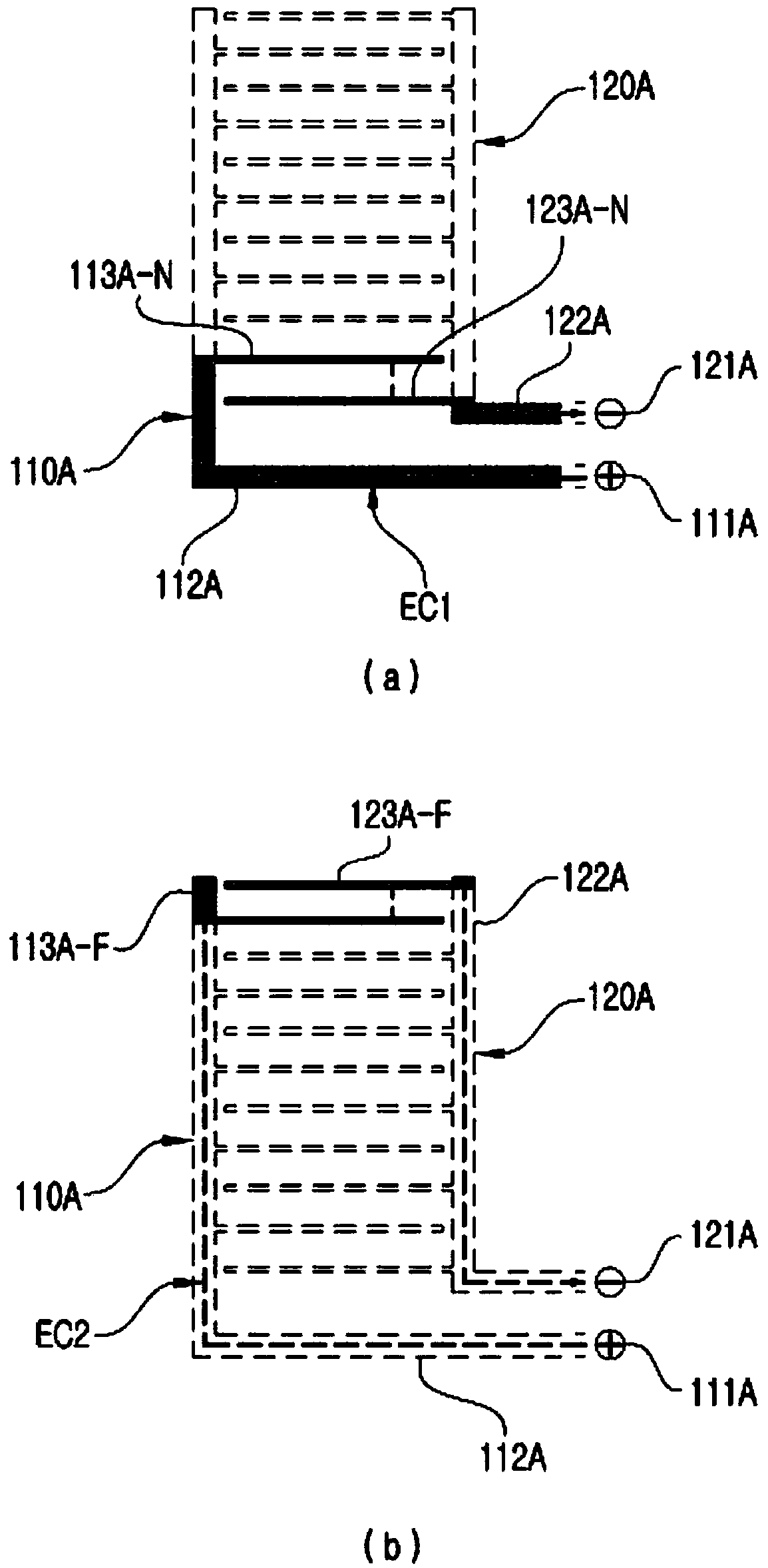

[0059] figure 1 It is a diagram showing an example of the electrode arrangement in the plate-shaped heating element 100A realized as the first embodiment according to the first aspect of the present invention.

[0060] The plate-shaped heating element 100A of this embodiment includes a first electrode 110A and a second electrode 120A that are paired to generate resistance heat to a heating substance.

[0061] The first electrode 110A includes a first power input point 111A, a first main electrode 112A, and a plurality of first bifurcated electrodes 113A.

[0062] The first power input point 111A is connected to the + pole or the-pole of the power source.

[0063] The first main power source 112A is formed to extend in a U-shape in the left-right direction with the first power input point 111A as a reference.

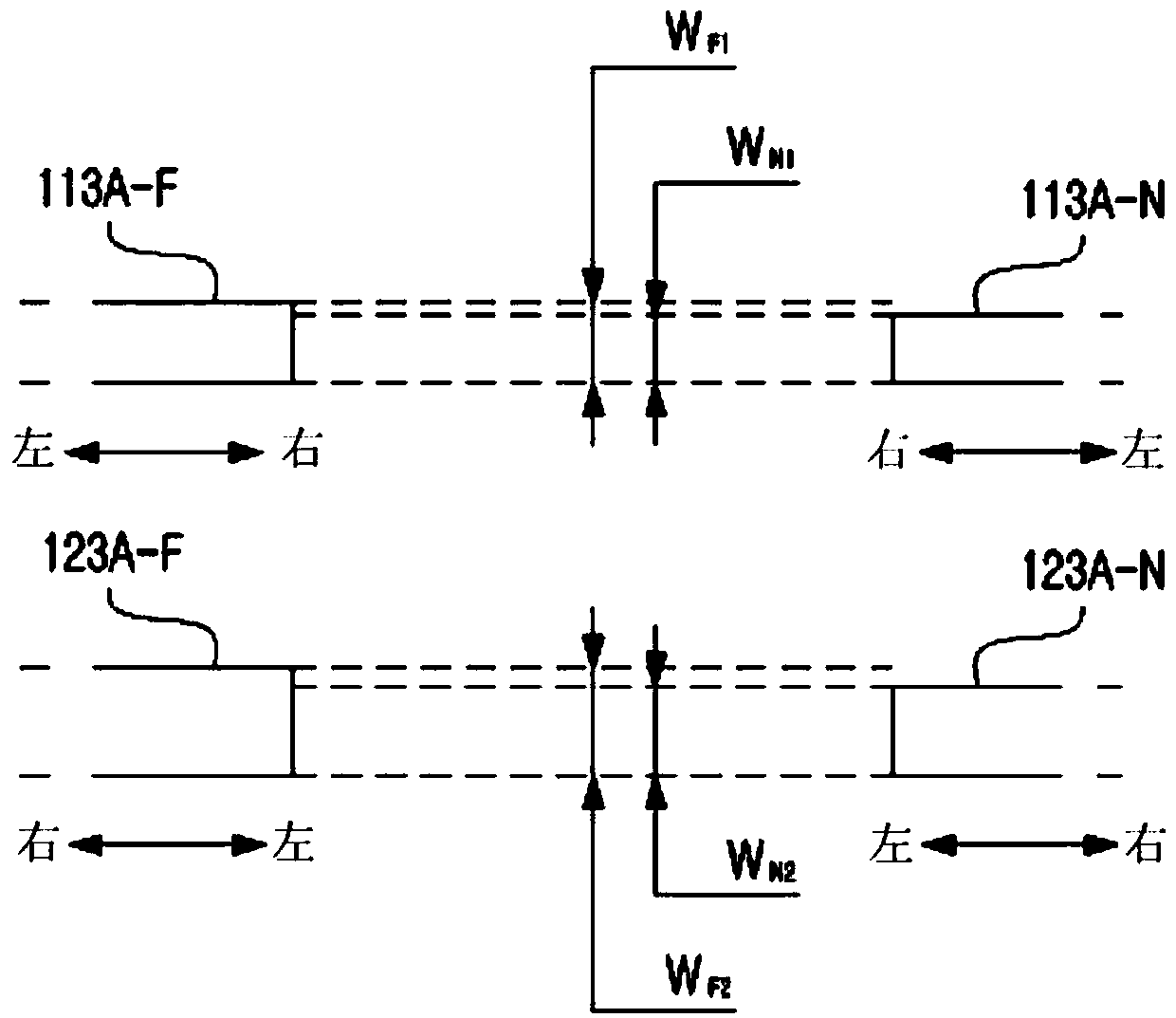

[0064] The plurality of first bifurcated electrodes 113A are bifurcated from the first main electrode 112A and extend in the inner direction, that is, the second electrode 120A si...

no. 3 example

[0086] Figure 5 It is a diagram showing an example of the electrode arrangement of the plate-shaped heating element 300A realized as the third embodiment according to the first aspect of the present invention.

[0087] Figure 5 In the example of, the main electrodes 312A, 322A of the first electrode 310A and the second electrode 320A extend in parallel from different power input points 311A, 321A. Also, the bifurcated electrodes 313A, 323A are alternately arranged from the respective main electrodes 312A, 322A. Here, similarly, the greater the distance from the power input points 311A, 321A, the greater the width of the bifurcated electrodes 313A, 323A.

no. 4 example

[0089] Image 6 It is a diagram showing an example of the electrode arrangement of the plate-shaped heating element 400A realized as the fourth embodiment according to the first aspect of the present invention.

[0090] The plate-shaped heating element 400A according to this embodiment also includes: a first electrode 410A, including a first power input point 411A, a first main electrode 412A, and a first bifurcated electrode 413A; a second electrode 420A, including a second power input point 421A, the second main electrode 422A, and the second bifurcated electrode 423A.

[0091] In this embodiment, the two bifurcated electrodes 413A and 423A are arranged in a circular arc shape. Also, the first power input point 411A and the second power input point 421A are arranged on two sides corresponding to each other on a line L passing through the center O of the bifurcation electrode 413A-L with the largest radius. That is, the first power input point 411A and the second power input poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com