Hydraulic control device of paddy field rotary tillage and leveling mechanism

A control device and hydraulic technology, which is applied in the fields of tillage implements, agricultural machinery and implements, applications, etc., can solve the problems of decreased working performance of the leveling mechanism, affecting the life of the hydraulic pump, and high temperature of the hydraulic oil, achieving small energy loss and prolonging the service life. , the effect of dynamic response and fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

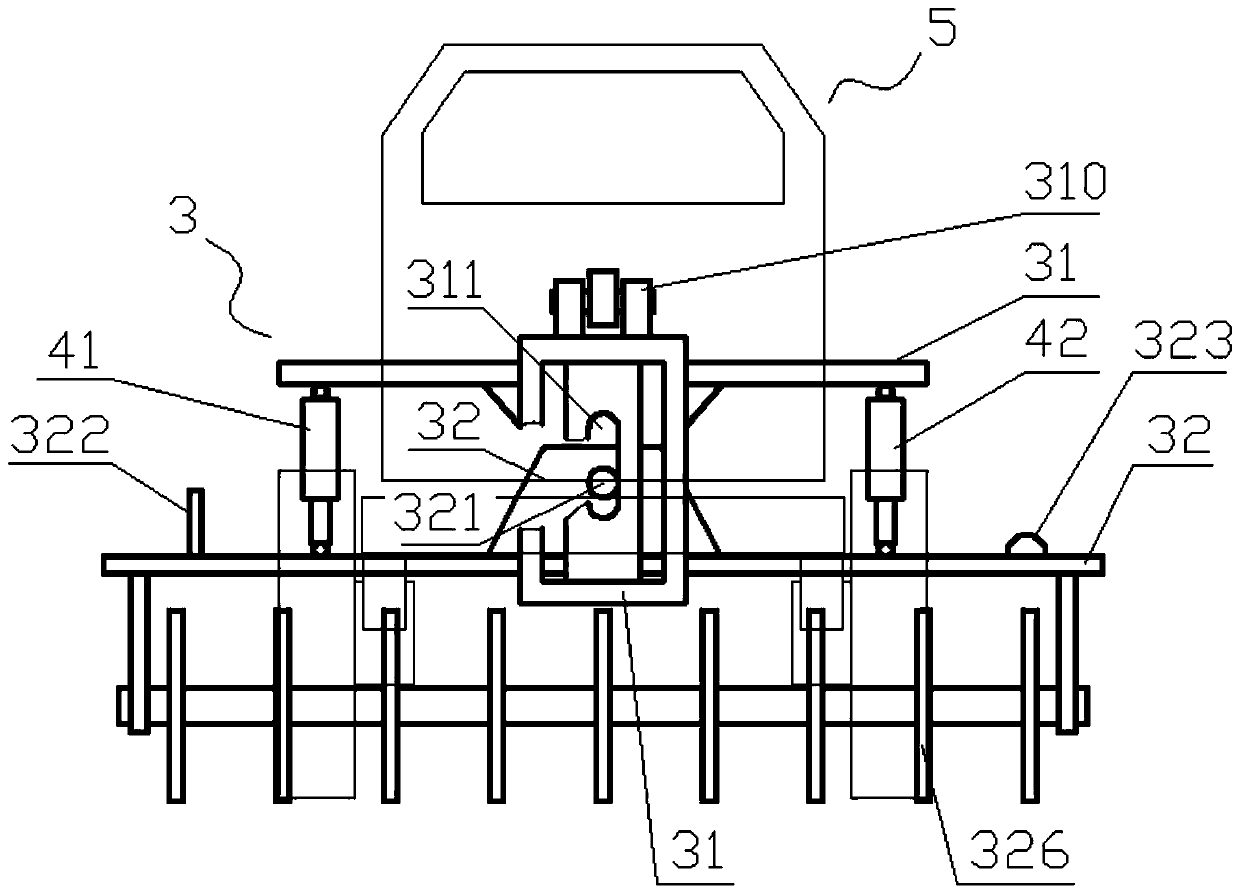

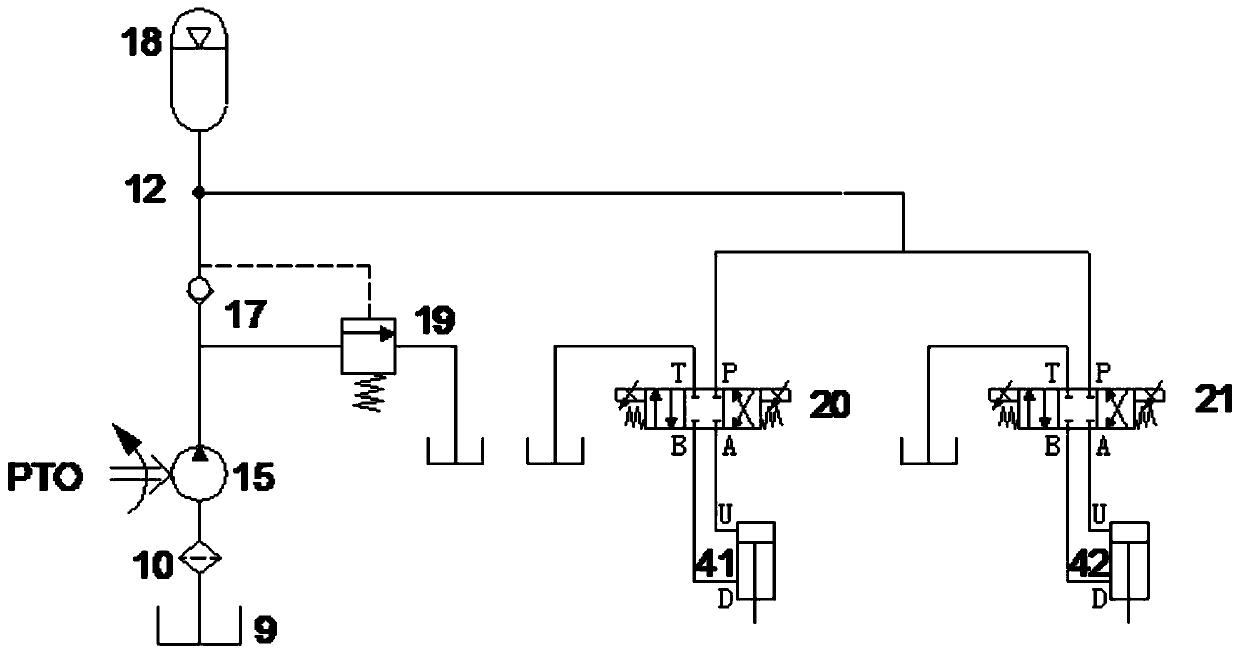

[0024] Such as figure 1 , The hydraulic control device of this embodiment is implemented on the leveling mechanism 3, which has a suspension frame 31, a rotary tillage mechanism frame 32 and two groups of hydraulic cylinders. The suspension frame 31 is suspended and connected with the tractor 5 through the hooking part 310 thereon, and the rotary tillage mechanism frame 32 is connected on the suspension frame 31 so that it can rotate and move up and down relative to the suspension frame. Specifically, a chute 311 is provided on the suspension frame 31, a rotating shaft 321 is provided on the rotary tillage mechanism frame 32, and the rotary tillage mechanism frame 32 is movably connected to the suspension frame 31 through the rotation of the rotary shaft 321 relative to the chute 311 or / and sliding up and down. . Of course, the chute can also be arranged on the rotary tillage mechanism frame 32, and the rotating shaft is arranged on the suspension frame 31. The rotary tillage...

Embodiment 2

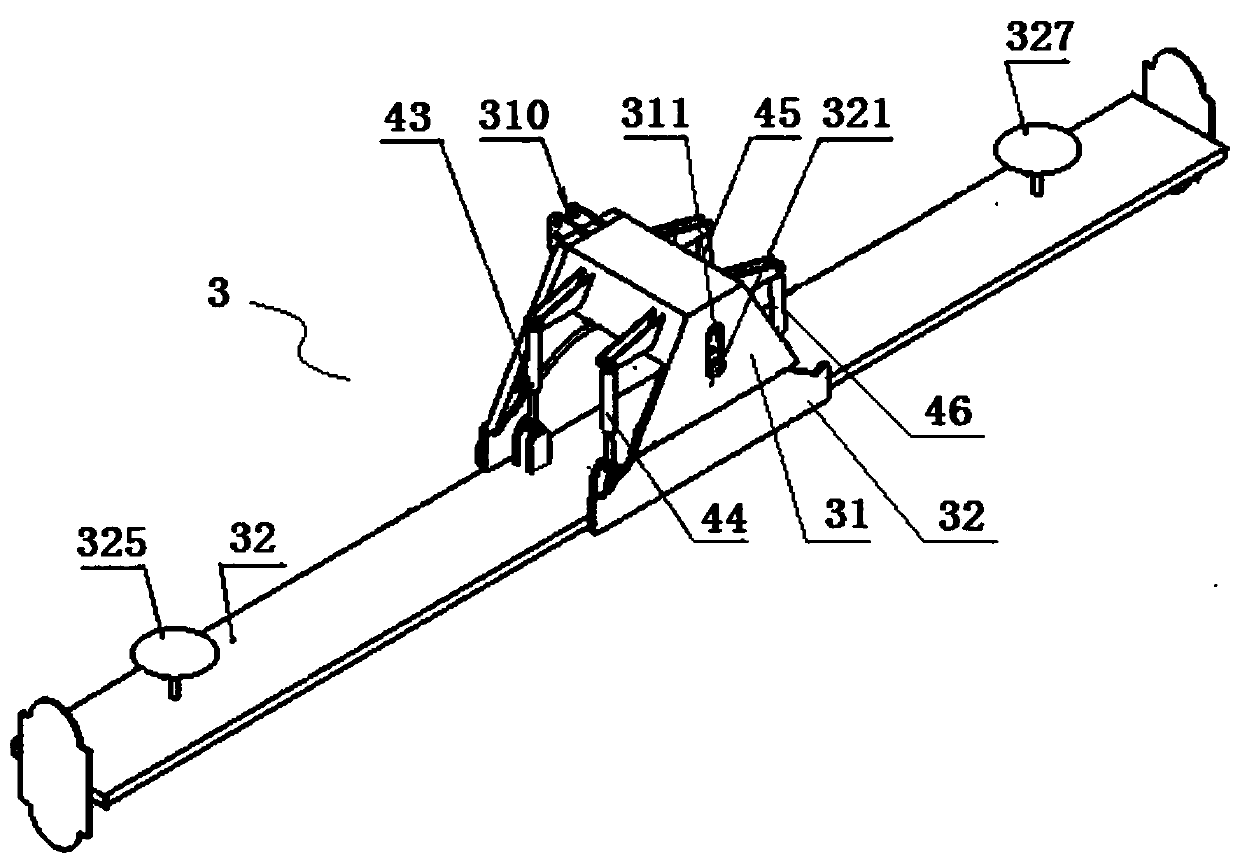

[0036] The hydraulic control device of this embodiment is implemented in such as image 3 On the leveling mechanism 3 shown, the leveling mechanism 3 has the same functional components as in Embodiment 1, including a suspension frame 31, a rotary tillage mechanism frame 32 and two groups of hydraulic cylinders. The suspension frame 31 is suspended and connected with the tractor through a articulated part 310 welded thereto. The symmetrical center of the suspension frame 31 is provided with a chute 311, and the rotary tillage mechanism frame 32 is provided with a rotating shaft 321 matched with the chute 311. The rotating shaft 321 is placed on the sliding In the groove 311 , the frame 32 of the rotary tiller mechanism is movably connected to the suspension frame 31 through the rotation of the rotating shaft 321 relative to the sliding groove 311 or / and sliding up and down. The hydraulic cylinders in this embodiment are placed vertically, and each group includes two hydraulic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com