Bait, making method thereof and special vacuum packaging bag

A production method and packaging bag technology, applied in the direction of packaging, transportation and packaging, packaging, etc. under vacuum/special atmosphere, to achieve the effect of strong attractiveness, improved softness, and soft texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The method of making the bait is as follows:

[0057] (1) Weigh 43Kg of fish, 20Kg of chicken liver, 15Kg of duck liver, 22Kg of dried shrimp, 30Kg of flour, 6Kg of milk powder, 0.2Kg of ethyl maltol, 25Kg of edible oil, 3Kg of salt, and 0.2Kg of preservative;

[0058] (2) Put each raw material described in step (1) into an automatic mixer, pulverize and mix and stir evenly, the stirring speed is 50r / min, and the stirring time is 25min, thereby making a meat sauce-like semi-finished product;

[0059] (3) Place the meat sauce-like semi-finished product prepared in step (2) on a stainless steel tray, and put it into an electric-controlled steam cabinet for aging treatment. The aging time is 20 minutes, and the aging temperature is 90° C.;

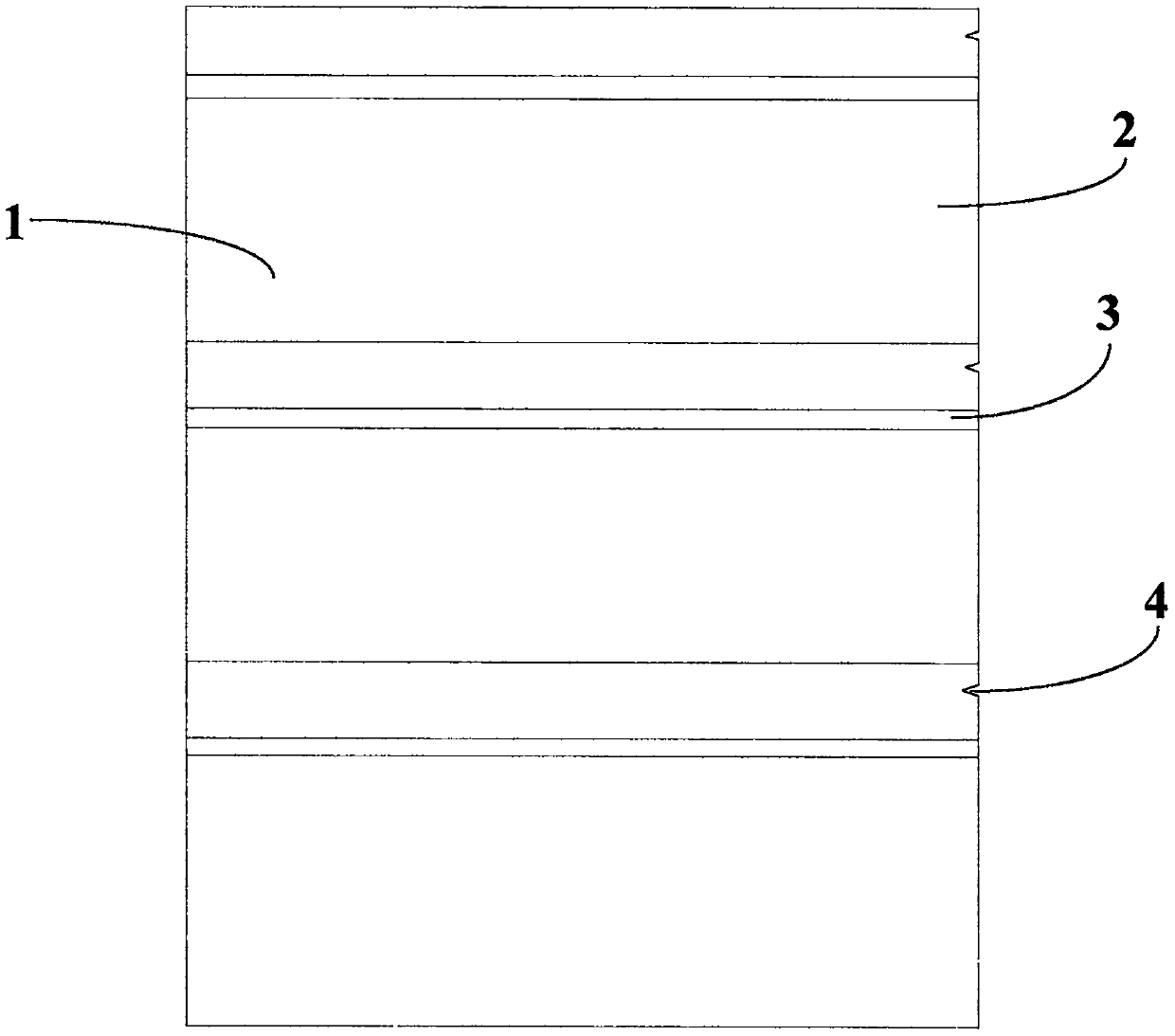

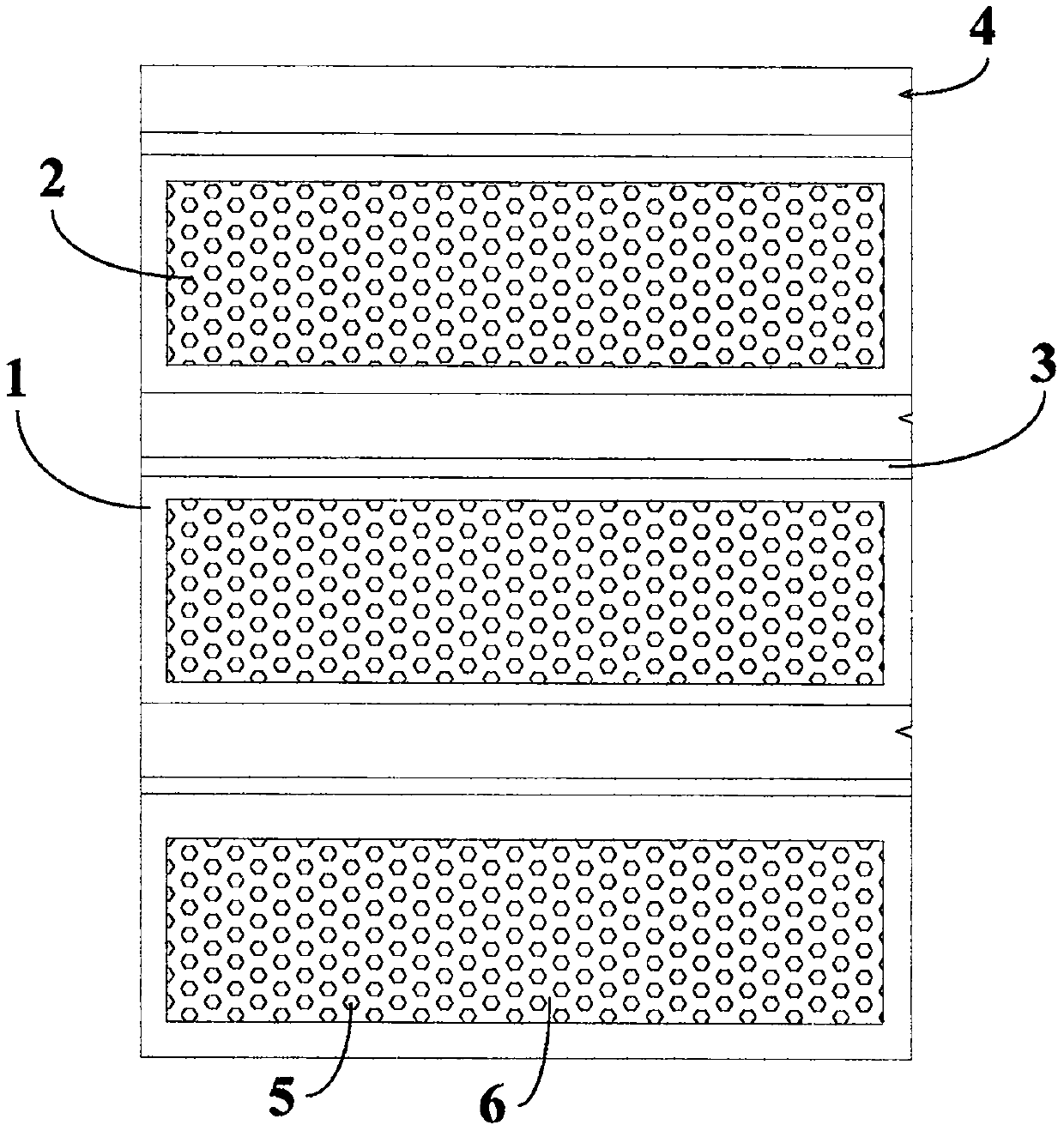

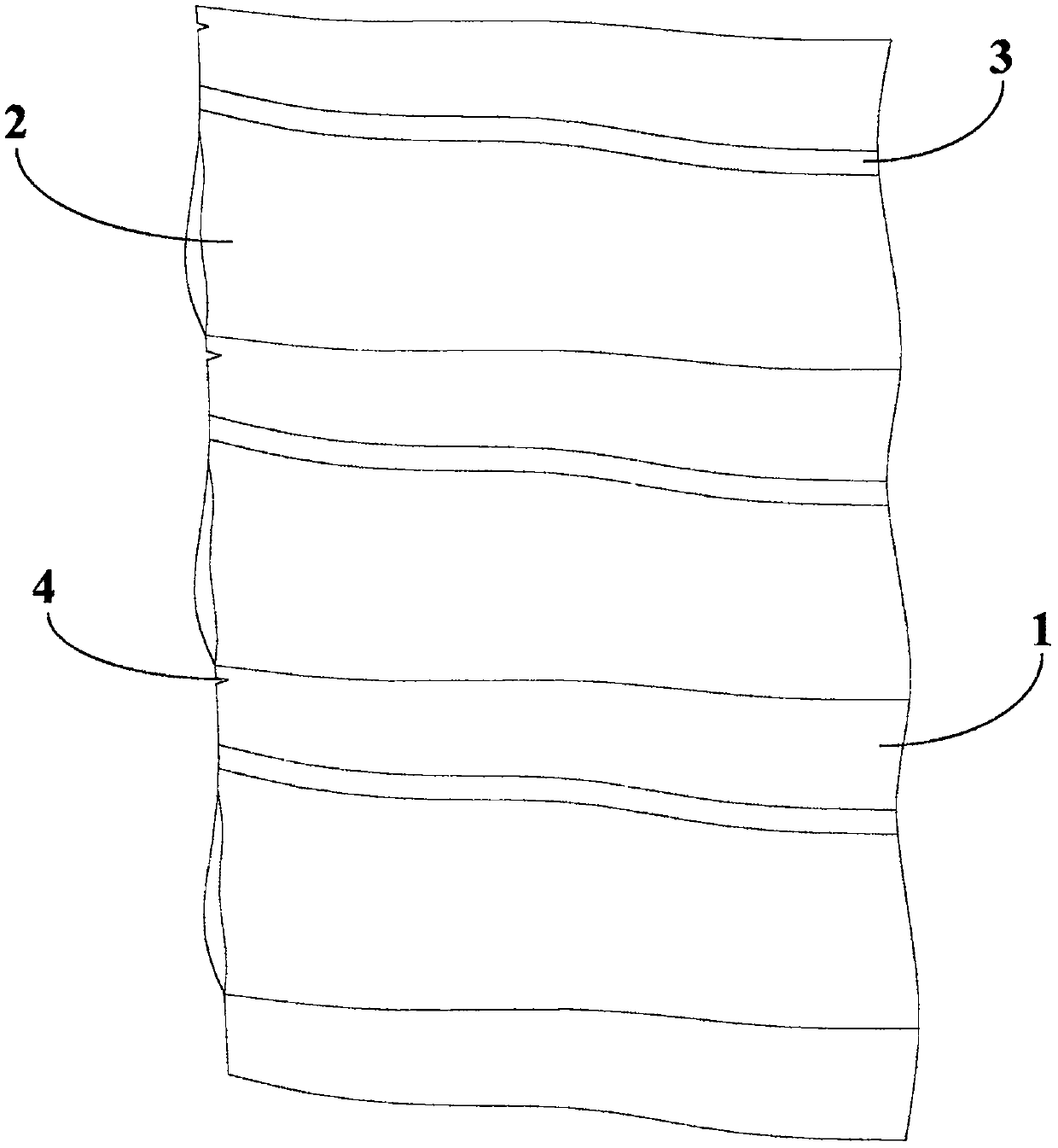

[0060] (4) weigh the product after aging treatment in step (3), and pack into vacuum packaging bags, vacuumize and seal;

[0061] (5) Put the vacuum-sealed raw materials in step (4) into a back-pressure sterilizer for sterilization, k...

Embodiment 2

[0063] (1) Weigh 40Kg of fish, 22Kg of chicken liver, 18Kg of duck liver, 25Kg of dried shrimp, 25Kg of flour, 10Kg of milk powder, 0.3Kg of ethyl maltol, 22Kg of edible oil, 4Kg of salt, and 0.25Kg of preservative;

[0064] (2) Put each raw material described in step (1) into an automatic mixer, pulverize and mix and stir evenly, the stirring speed is 45r / min, and the stirring time is 28min, thereby making a meat sauce-like semi-finished product;

[0065] (3) Place the meat sauce-like semi-finished product prepared in step (2) on a stainless steel tray, and put it into an electric-controlled steam cabinet for aging treatment. The aging time is 18 minutes, and the aging temperature is 95° C.;

[0066] (4) weigh the product after aging treatment in step (3), and pack into vacuum packaging bags, vacuumize and seal;

[0067] (5) Put the vacuum-sealed raw materials in step (4) into a back-pressure sterilizer for sterilization, keep the temperature at 125°C for 35 minutes to steril...

Embodiment 3

[0069] (1) Weigh 48Kg of fish, 18Kg of chicken liver, 13Kg of duck liver, 30Kg of dried shrimp, 40Kg of flour, 8Kg of milk powder, 0.5Kg of ethyl maltol, 30Kg of edible oil, 5Kg of salt, and 0.3Kg of preservative;

[0070] (2) Put each raw material described in step (1) into an automatic mixer, pulverize and mix and stir evenly, the stirring speed is 40r / min, and the stirring time is 30min, thereby making a meat sauce-like semi-finished product;

[0071] (3) Place the meat sauce-like semi-finished product prepared in step (2) on a stainless steel tray, and put it into an electric-controlled steam cabinet for aging treatment. The aging time is 15 minutes, and the aging temperature is 100° C.;

[0072] (4) weigh the product after aging treatment in step (3), and pack into vacuum packaging bags, vacuumize and seal;

[0073] (5) Put the vacuum-sealed raw materials in step (4) into a back pressure sterilizer for sterilization, sterilize at a constant temperature of 130°C for 28 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com