Nut shell breaking method and nut shell breaking machine capable of automatically controlling shell breaking pressure

The technology of a nut cracking machine and power mechanism, which is applied in the field of nut cracking method and nut cracking machinery, can solve the problems of environmental and worker hazards, poor effect, high labor intensity, etc., and is easy to manufacture, install and maintain , The efficiency of shell breaking is improved, which is beneficial to the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

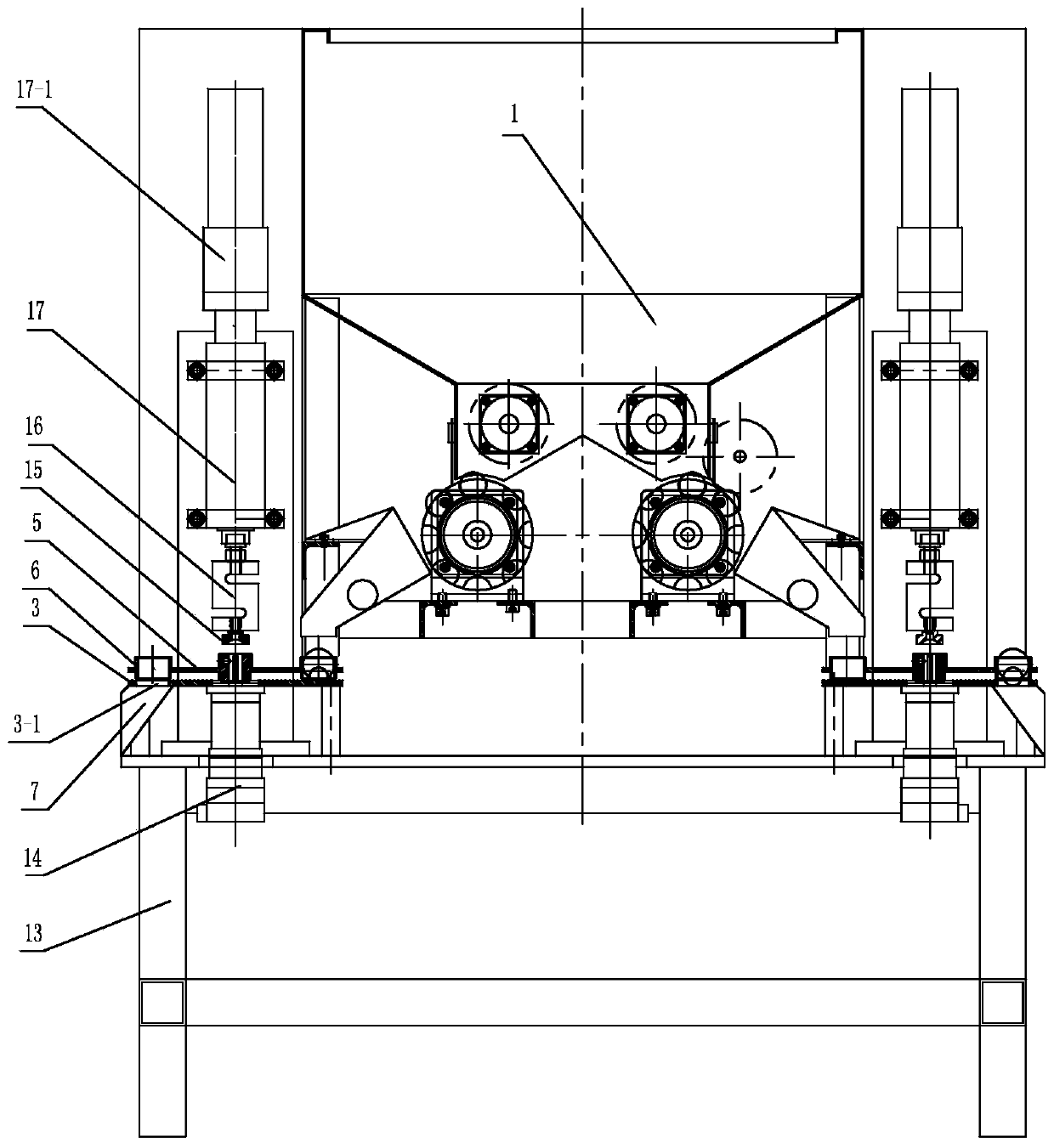

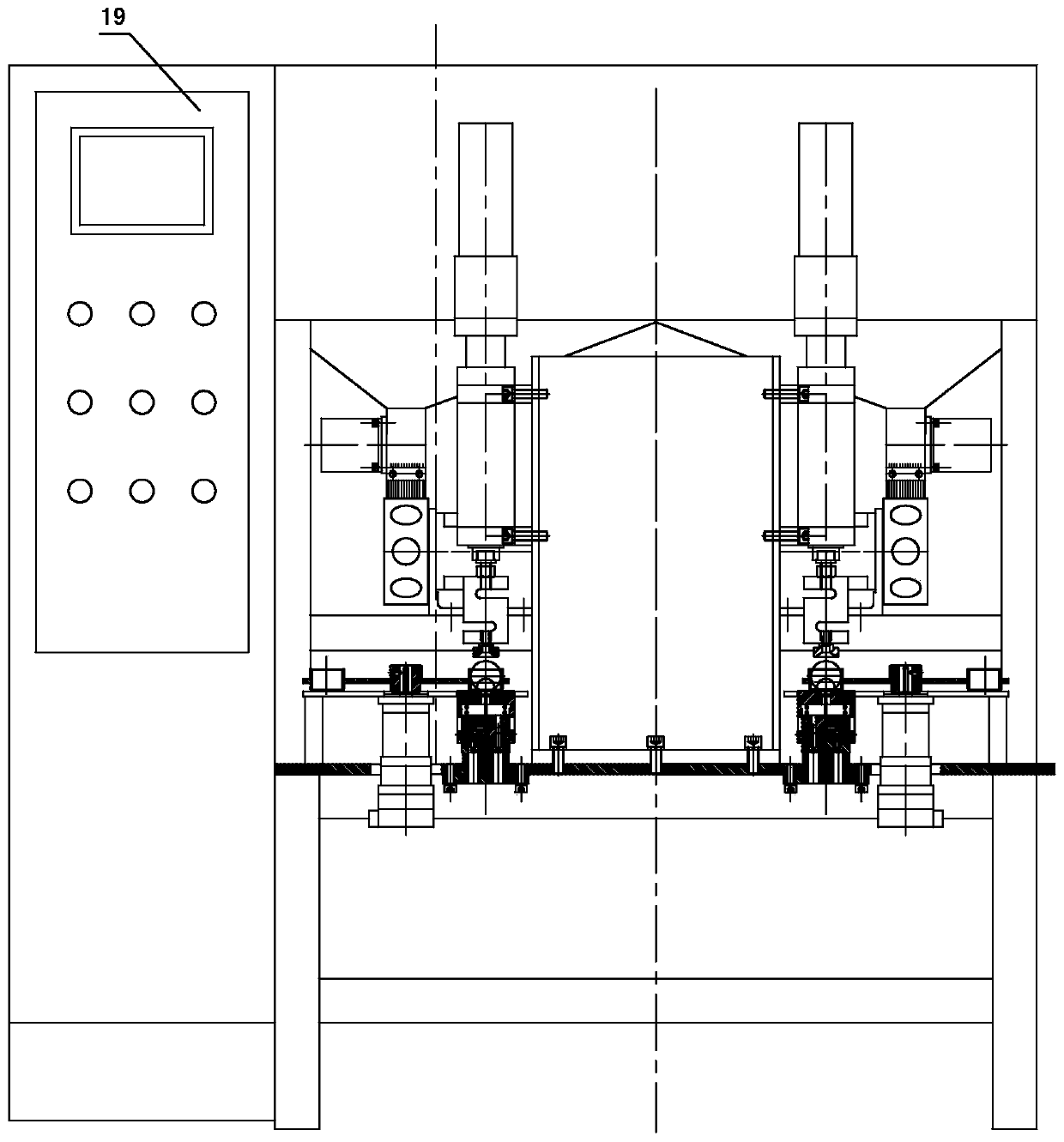

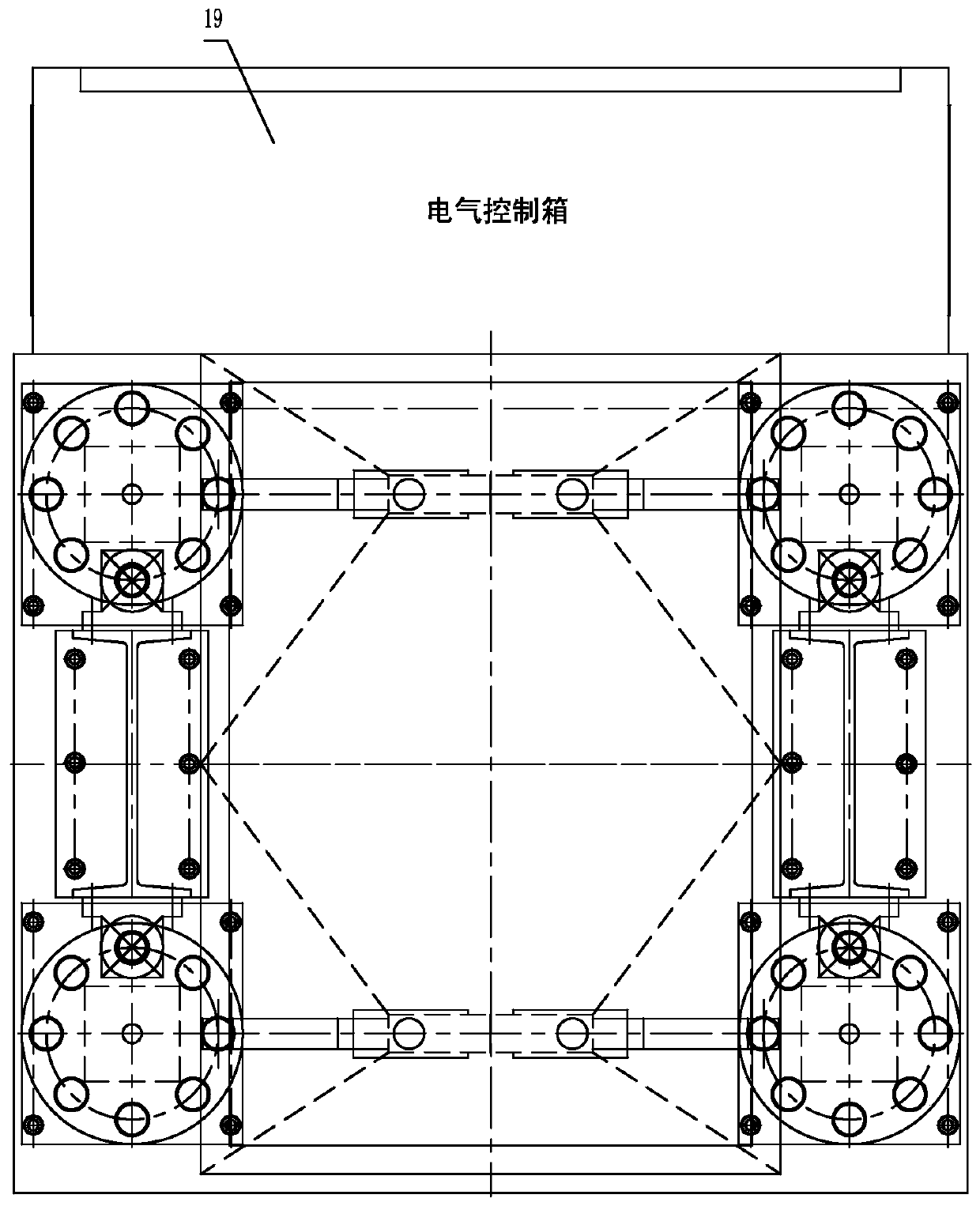

[0030] Further description will be given below in conjunction with the embodiments shown in the accompanying drawings.

[0031] The cracking method for nuts provided by the invention is carried out as follows:

[0032] 1) Put the nuts into a casing that penetrates up and down and has a diameter larger than the nuts; the casing acts as a wall, and usually the inner diameter is 0.5-2mm larger than the diameter of the nuts to prevent the nuts from escaping when they open;

[0033] 2) Aim at one end of the nut to apply a pressure that gradually increases and is parallel to the axis of the casing, and provide a reaction force that is the same in magnitude as the pressure and opposite in direction at the other end of the nut; a sensor monitors the pressure on-line;

[0034] 3) At least one of the pressing force and the reaction force is applied through the opening knife;

[0035] 4) When the sensor detects a sudden decrease in the top pressure, it indicates that the nuts have been ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com