Reinforcing steel bar bending machine

A bending machine and steel bar technology, applied in the field of steel bar bending machine, can solve the problems of heavy weight, laborious manual movement, etc., and achieve the effect of small size, stable operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

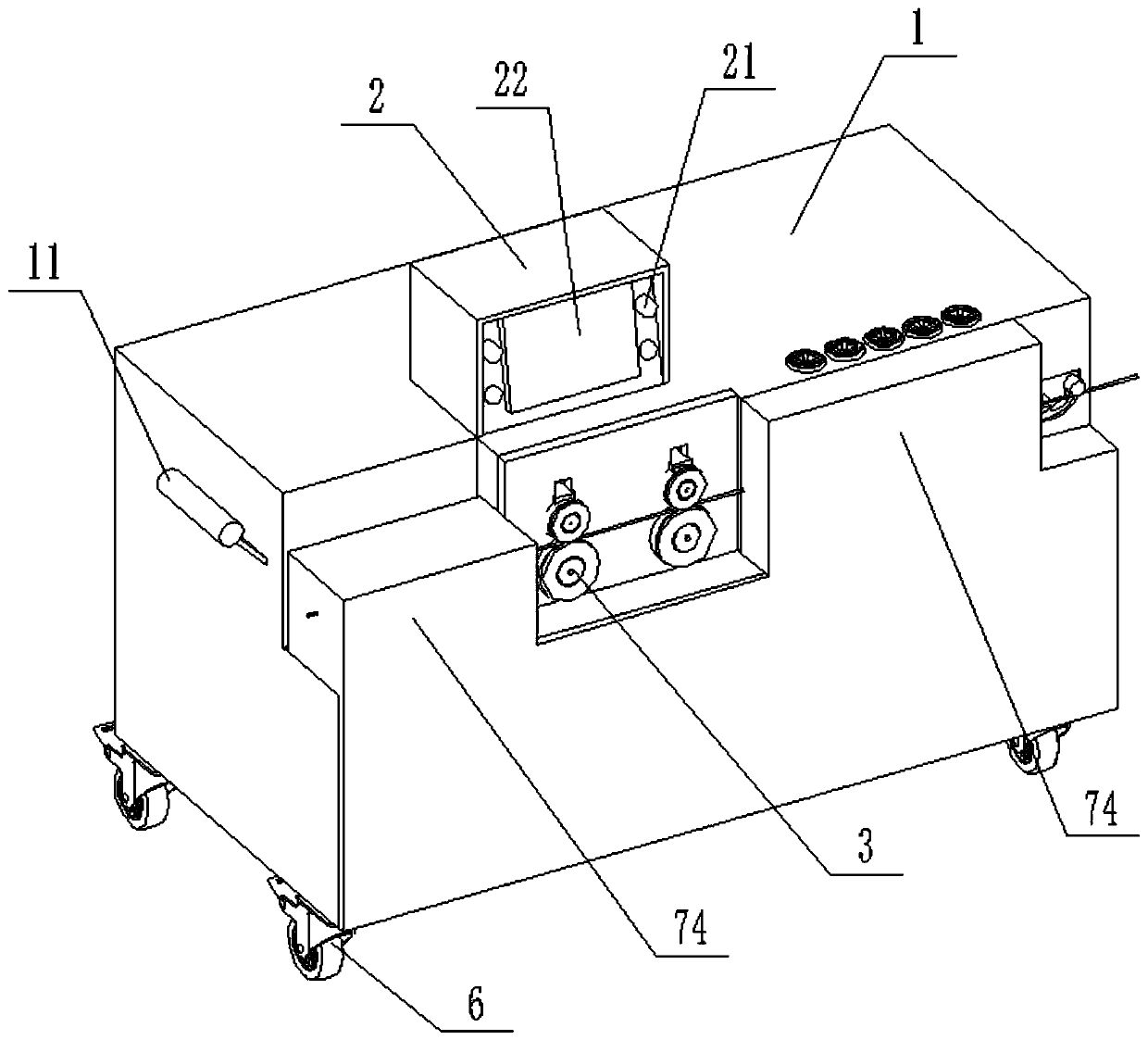

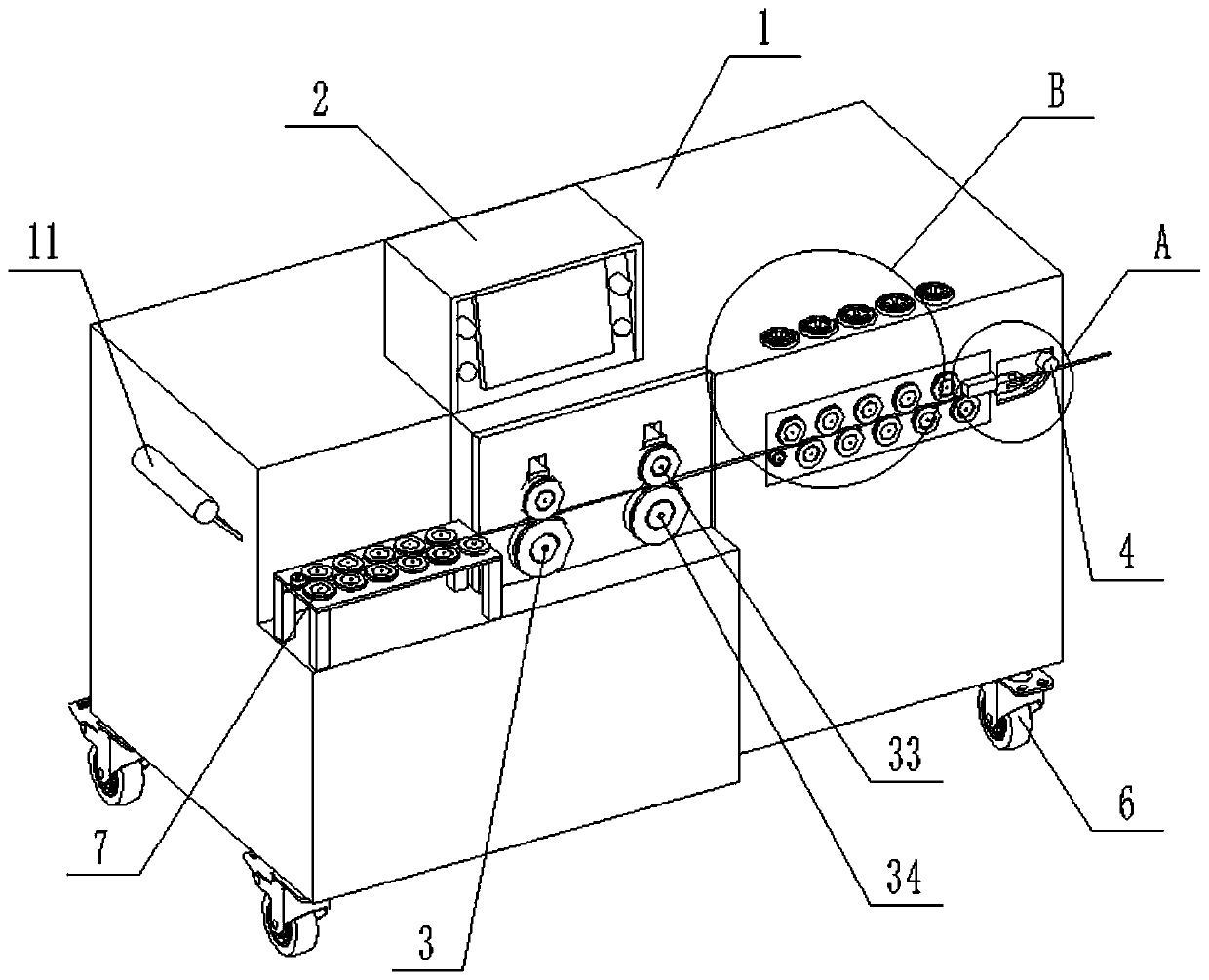

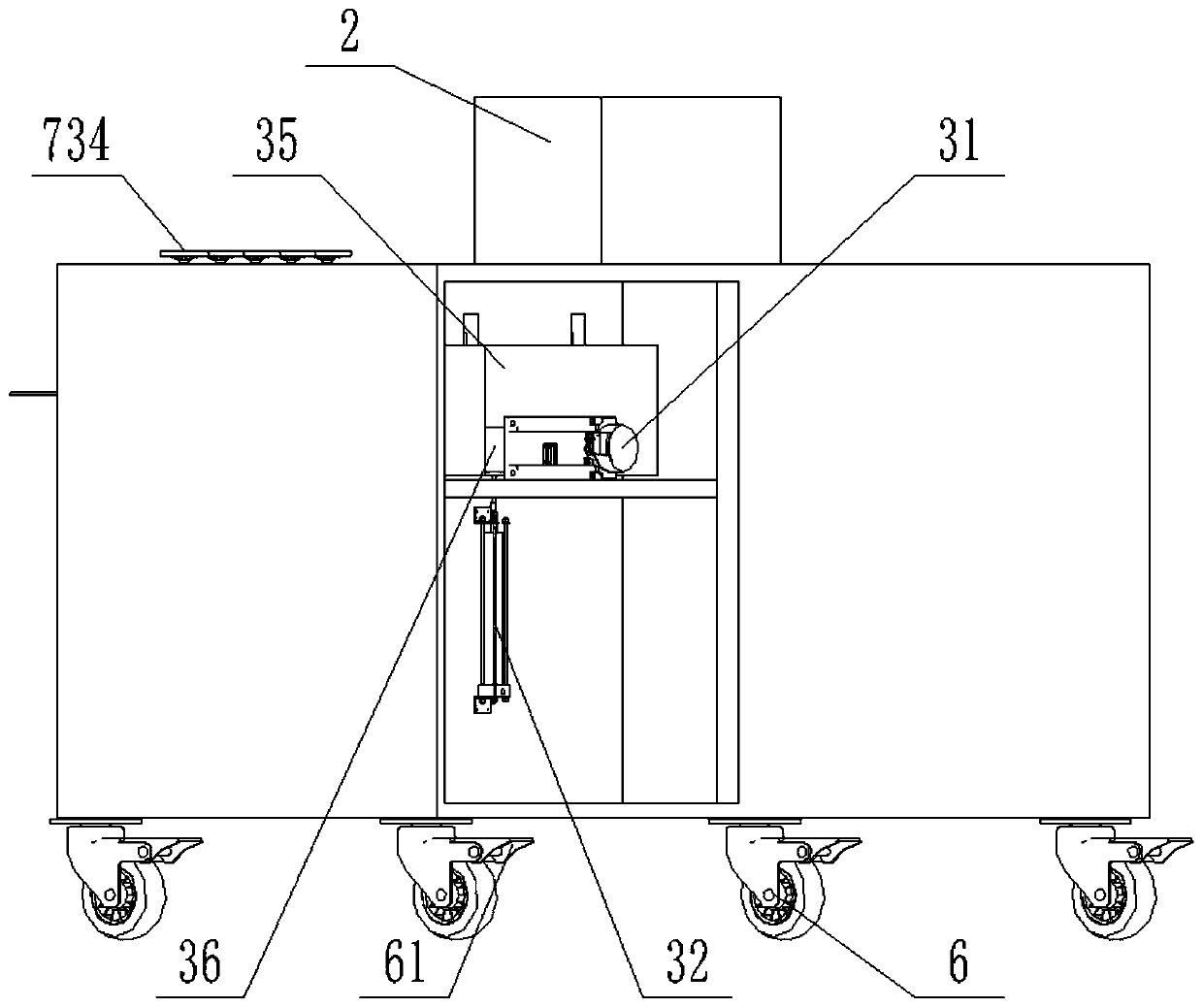

[0056] A steel bar bending machine, comprising a chassis, a control box, a conveying assembly, a bending assembly and a cutting assembly, the control box, the conveying assembly, the bending assembly and the cutting assembly being arranged on the chassis;

[0057] The control box includes a controller, an input device and a display device; the input device and the display device are integrated.

[0058] The conveying assembly includes a conveying motor, a clamping reciprocating part, and a clamping wheel and a feeding wheel arranged up and down. The conveying motor drives the feeding wheel to rotate, and the clamping reciprocating part drives the clamping wheel to reciprocate; the clamping The wheel is arranged directly above the feeding wheel; the clamping wheel and the feeding wheel have two groups, and the feeding wheel of the two groups is connected with the conveying motor through a synchronous gearbox; reducer.

[0059] The bending assembly includes a bending motor, a b...

Embodiment 2

[0069] A steel bar bending machine, including a chassis, a conveying assembly, a bending assembly and a cutting assembly, the conveying assembly, bending assembly and cutting assembly are arranged on the chassis;

[0070] The conveying assembly includes a conveying motor, a clamping reciprocating part, and a clamping wheel and a feeding wheel arranged up and down. The conveying motor drives the feeding wheel to rotate, and the clamping reciprocating part drives the clamping wheel to reciprocate; the clamping The wheel is arranged directly above the feeding wheel; the clamping wheel and the feeding wheel have two groups, and the feeding wheel of the two groups is connected with the conveying motor through a synchronous gearbox; reducer.

[0071] The bending assembly includes a bending motor, a bending shaft and a top block, the bending motor drives the bending shaft to move, the top block is located between the bending shaft and the conveying assembly; the top block is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com