Preparation method of sheet-like strontium titanate nano single crystal

A technology of strontium titanate and single crystals, which is applied in the field of preparation of flake strontium titanate nano single crystals, can solve the problems of high equipment requirements, long preparation process, incomplete reaction, etc., and achieve high process complexity, large surface area and purity , The effect of easy reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

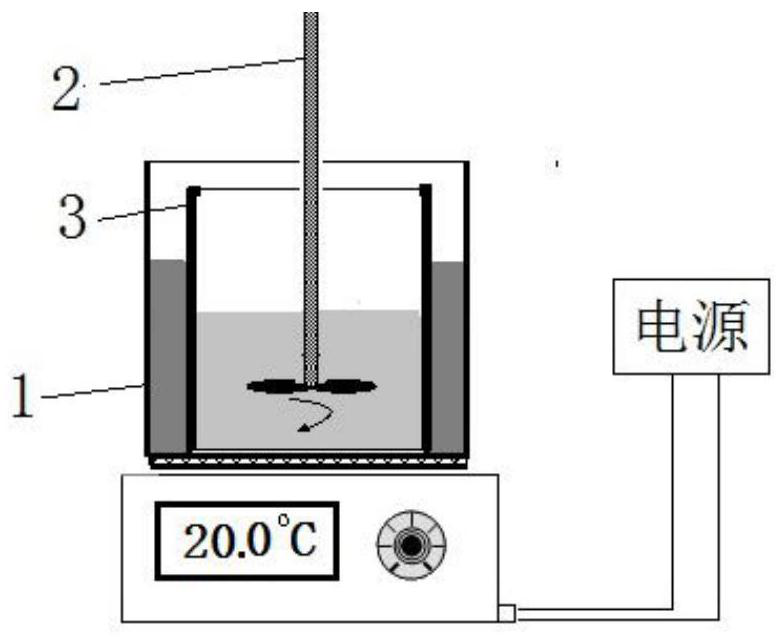

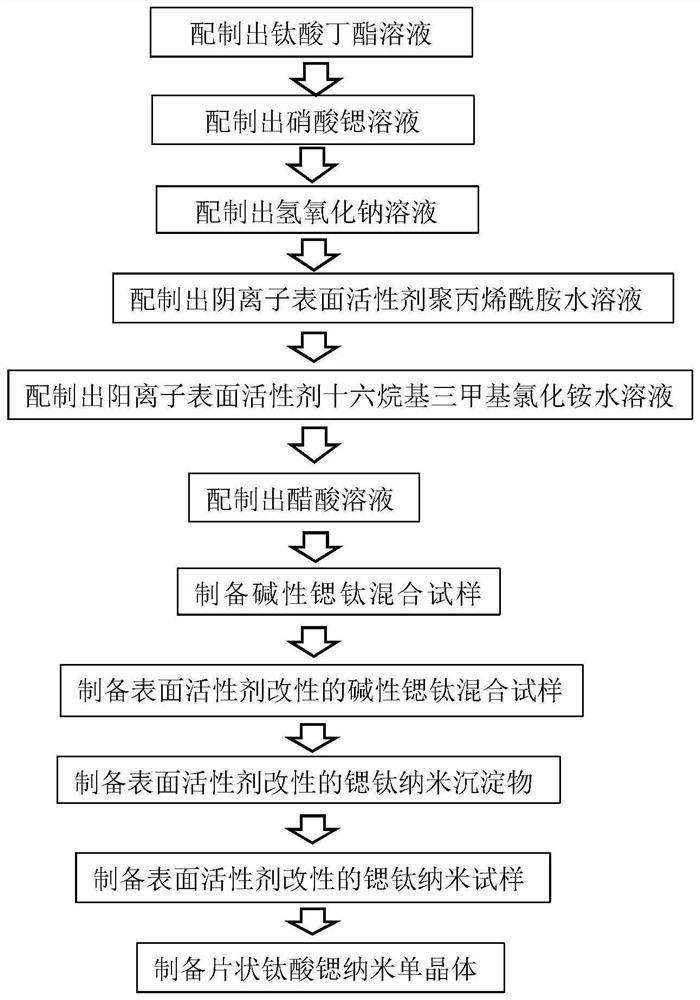

Method used

Image

Examples

Embodiment 1

[0050] Example 1: Preparation of flaky strontium titanate nano single crystals with a particle diameter of 15 nm.

[0051] Step 1, using butyl titanate and absolute ethanol to prepare a 0.109mol / L butyl titanate solution;

[0052] (1a) 50mL absolute ethanol is packed into a beaker;

[0053] (1b) With a needle tube, the density is 0.966g / cm 3 , a liquid butyl titanate with a volume of 1.92 mL;

[0054] (1c) Inject the butyl titanate extracted by the needle into 50 mL of absolute ethanol, and at the same time, mix and stir with an electric mechanical stirrer at a speed of 40 rpm for 3 minutes to obtain a butyl titanate solution with a concentration of 0.109 mol / L.

[0055] Step 2, using strontium nitrate and deionized water to prepare a strontium nitrate solution with a concentration of 0.032mol / L.

[0056] (2a) Dissolving 3.39 g of strontium nitrate into 500 mL of deionized water and mixing to prepare a strontium nitrate aqueous solution with a concentration of 0.032 mol / L; ...

Embodiment 2

[0081] Example 2: Preparation of flaky strontium titanate nano single crystals with a particle diameter of 20 nm.

[0082]Step A, using butyl titanate and absolute ethanol to prepare a 0.347mol / L butyl titanate solution;

[0083] First put 50mL of absolute ethanol into a beaker; then, use a needle to extract 3 , liquid butyl titanate with a volume of 6.112mL; after that, inject the butyl titanate extracted by the needle into 50mL of absolute ethanol, and at the same time mix and stir with an electric mechanical stirrer at a speed of 40 rpm for 3 minutes to obtain The concentration is 0.347mol / L butyl titanate solution.

[0084] Step B, using strontium nitrate and deionized water to prepare a strontium nitrate solution with a concentration of 0.175mol / L.

[0085] First, dissolve 18.52g of strontium nitrate into 500mL of deionized water and mix to prepare a strontium nitrate aqueous solution with a concentration of 0.175mol / L; then, place the funnel on the instrument support, ...

Embodiment 3

[0104] Example 3: Preparation of flaky strontium titanate nano single crystals with a particle diameter of 30 nm.

[0105] Step 1, using butyl titanate and absolute ethanol to prepare a 0.689mol / L butyl titanate solution;

[0106] (1.1) Put 50mL absolute ethanol into a beaker;

[0107] (1.2) Use a needle to extract a density of 0.966g / cm 3 , a liquid butyl titanate with a volume of 12.14 mL;

[0108] (1.3) Inject the butyl titanate extracted by the needle into 50 mL of absolute ethanol, and at the same time, mix and stir with an electric mechanical stirrer at a speed of 40 rpm for 3 minutes to obtain a butyl titanate solution with a concentration of 0.689 mol / L.

[0109] Step 2, use strontium nitrate and deionized water to prepare a strontium nitrate solution with a concentration of 0.425mol / L.

[0110] (2.1) Dissolve 44.97g of strontium nitrate into 500mL of deionized water and mix to prepare a strontium nitrate solution with a concentration of 0.425mol / L;

[0111] (2.2) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com