An integrated sludge dewatering equipment

An integrated technology for sludge dehydration, applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/thickened sludge treatment, etc. Solve the problems of low working efficiency of the mud discharge device and achieve the effect of improving the drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

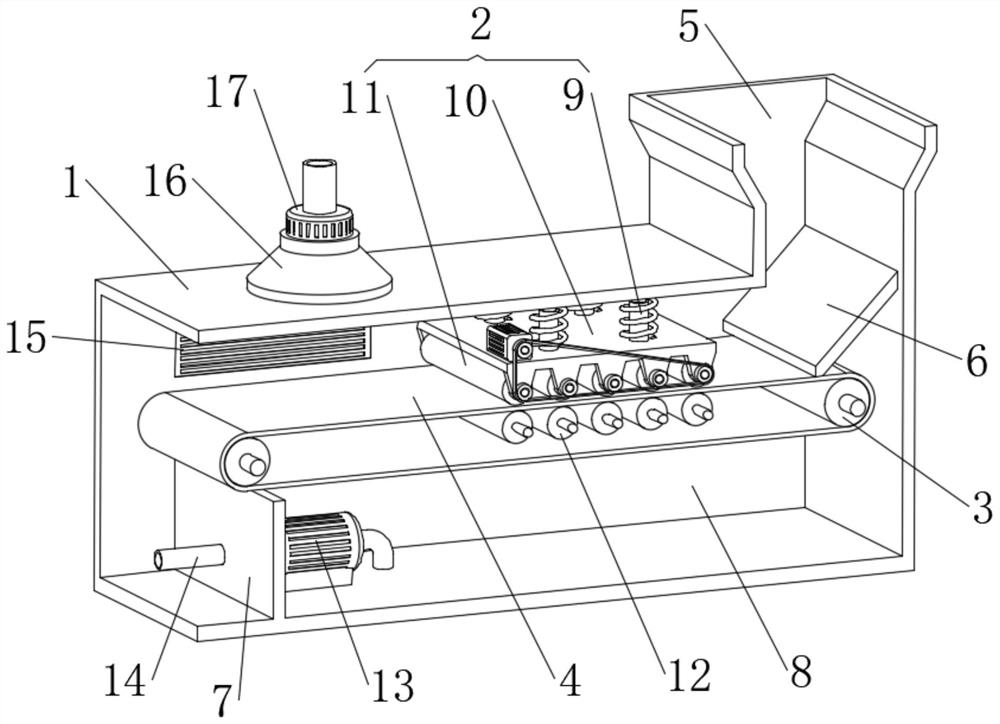

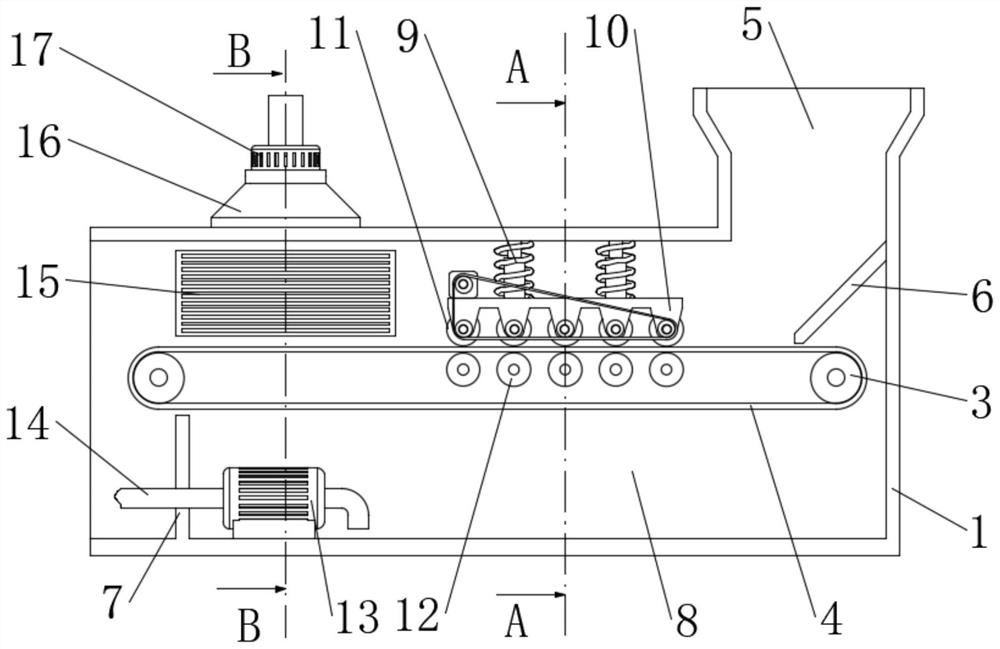

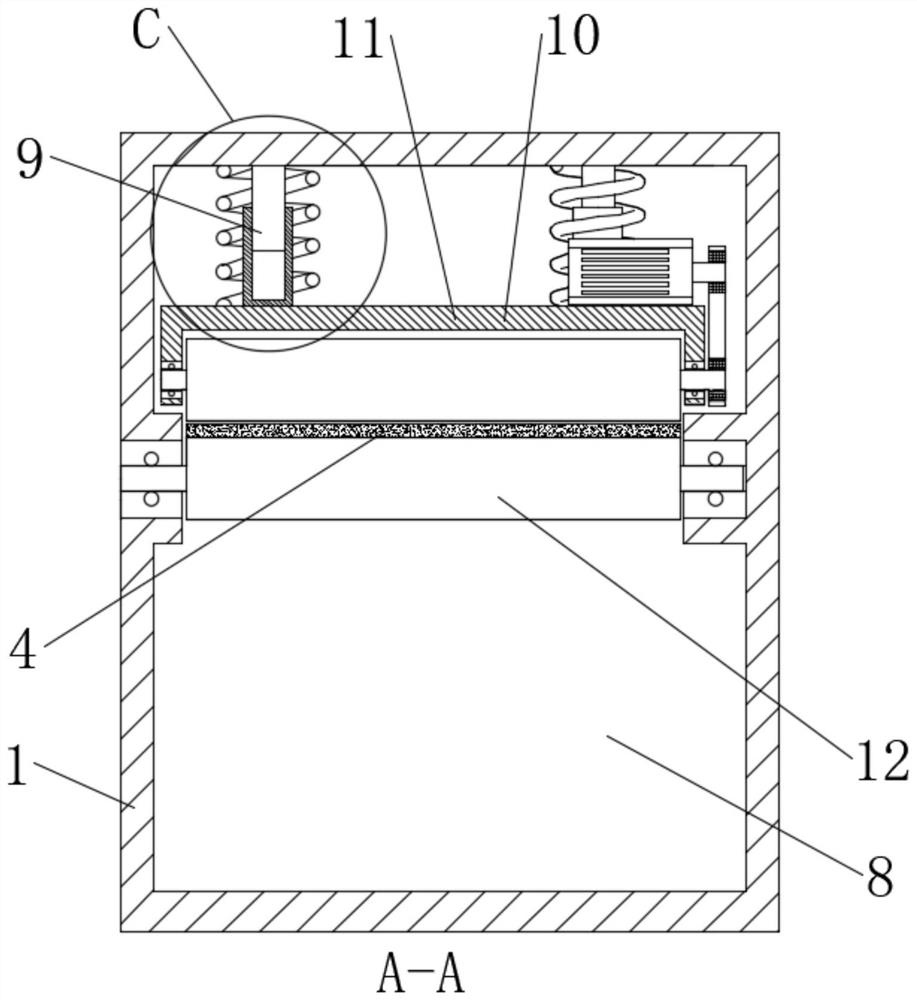

[0021] The present invention provides Figure 1-5 An integrated sludge dewatering apparatus shown, comprises a dehydrated body, the interior of the dewatering conveying roller body 1 is provided with a pair of horizontally disposed symmetrically 3, the conveying roller 3 is rotatably connected by a shaft and the inner wall of a dehydrated body, two filter belt 4 is connected to the positive, the dehydration on one surface of the body defines a feed inlet, close to the feed hopper above the feed port 5 is welded, the feed por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com