A kind of thermosetting resin glue and its application method and products obtained after application

A technology of resin glue and thermosetting, which is applied in the field of thermosetting resin glue and its application method and products after application, and can solve the problems of low hot-melt temperature, low 180° linear peel strength, unevenness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

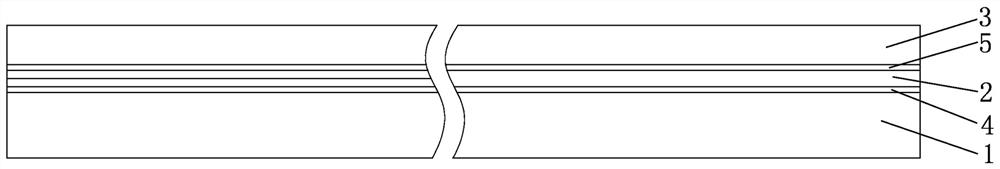

Image

Examples

Embodiment Construction

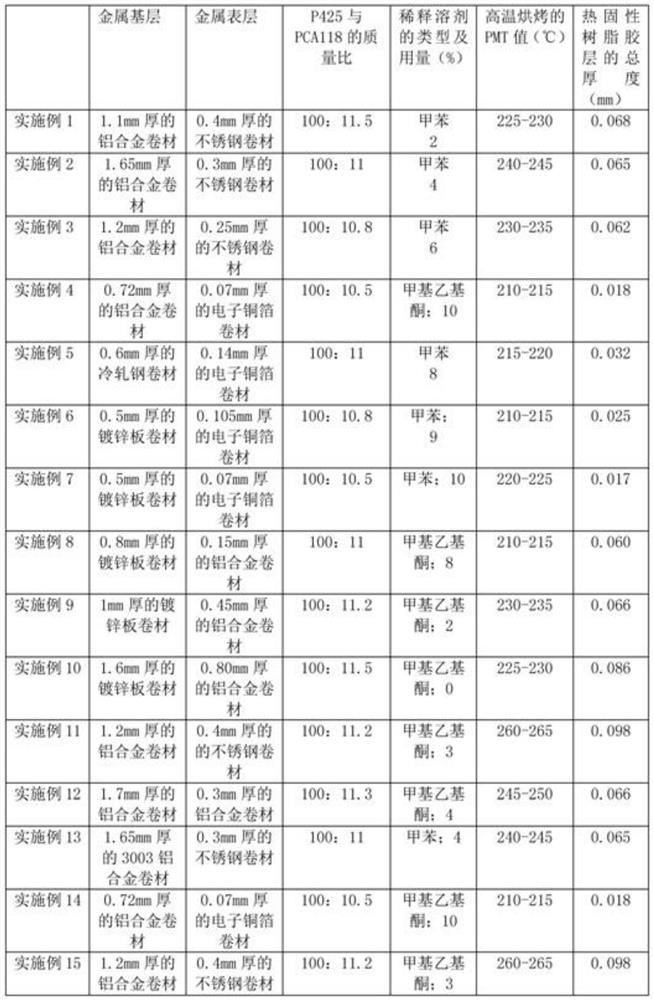

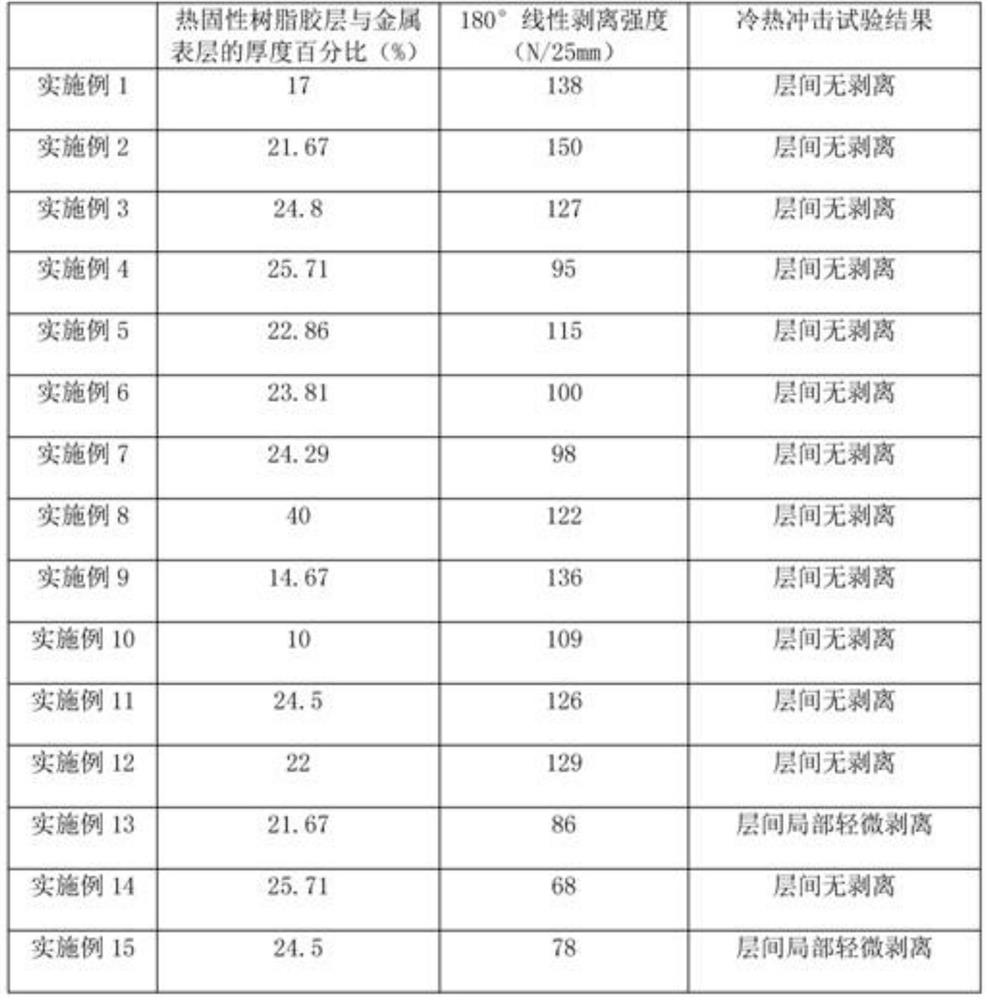

[0029] Now specifically state the embodiment of the thermosetting resin glue of the present invention and its application method and the product obtained after application:

[0030] A thermosetting resin glue, which is mixed with resin solution P425 and resin solution PCA118 in a mass ratio of 100:10.5-11.5, and then diluted with a diluting solvent to make a thermosetting resin glue. An organic solvent that has good solubility and does not react with the glue, based on the total mass of the thermosetting resin glue as 100%, the amount of diluting solvent is 0-10%.

[0031] A method for applying thermosetting resin glue, which is applied to the production of bimetallic composite plate rolls, specifically comprising the following steps: (1) preparing a metal base layer 1 and a metal surface layer 3, and placing the metal base layer 1 on the surface to be composited and the metal surface layer 3 The surface to be compounded is respectively coated with a layer of the thermosetting r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com