Two-component polyurethane adhesive and preparation method thereof

A two-component polyurethane and adhesive technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problem that the cold-formed aluminum is difficult to reach, the molecular weight is not high, and the ratio of the soft and hard segments of the adhesive is not high. Reasonable and other issues to achieve the effect of increasing medium resistance and strength, increasing ductility and wettability, and achieving strength and ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

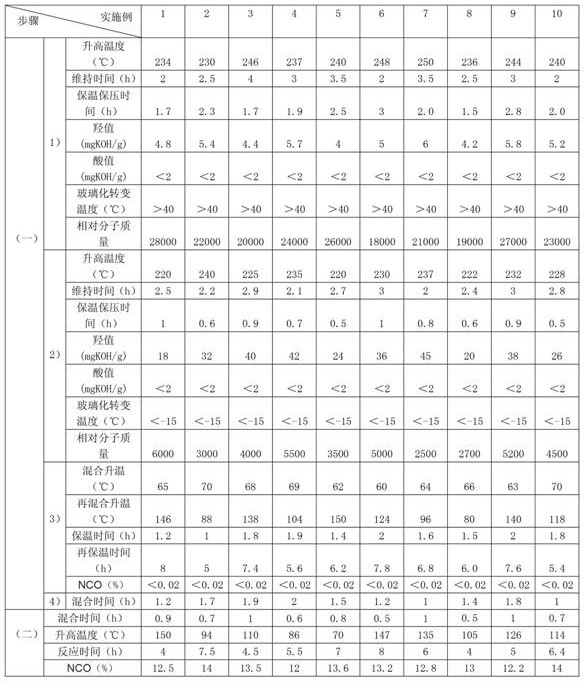

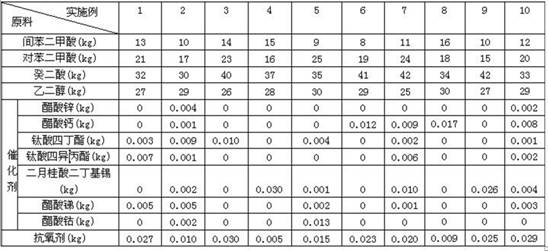

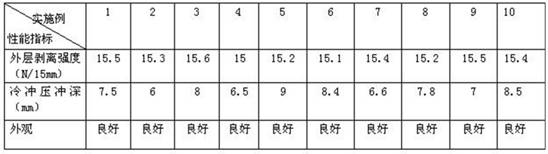

[0029] Embodiment 1-10 Two-component polyurethane adhesive and preparation method thereof

[0030] Examples 1-10 are respectively a two-component polyurethane adhesive and its preparation method, and the raw materials for making them are shown in Table 1-5, wherein, examples 1-10 all use two kinds of polyester polyols to show the difference , especially represented by polyester polyol A and polyester polyol B respectively, "A" and "B" have no practical technical meaning.

Embodiment 1

[0031] The preparation method of the two-component polyurethane adhesive of embodiment 1 carries out according to the following steps:

[0032] (1) Preparation of the main agent

[0033] 1) Preparation of polyester polyol A

[0034] ①Esterification reaction: Put isophthalic acid, terephthalic acid, neopentyl glycol, ethylene glycol, and antioxidants into the reactor, and nitrogen gas is introduced while heating up. After the reaction starts, the nitrogen gas is withdrawn and the temperature is raised. To 234°C, maintain the temperature for 3h;

[0035] ②Polycondensation reaction: add catalyst, maintain the reaction temperature of 234°C, and vacuumize the reaction kettle at a speed of -0.01MPa / 30min. After the vacuum degree in the kettle is increased from -0.01MPa to -0.1MPa, keep the temperature and pressure for 1.7h, that is A polyester polyol A having a hydroxyl value of 4.8 mgKOH / g and an acid value of <2 mgKOH / g with a relative molecular mass of 20,000 was obtained;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com