Measurement method for underframe coverage of urban rail car body

A measurement method and car body technology, applied in railway vehicle testing, program control, instruments, etc., can solve problems such as difficult to measure efficiency, error measurement, etc., and achieve a good overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

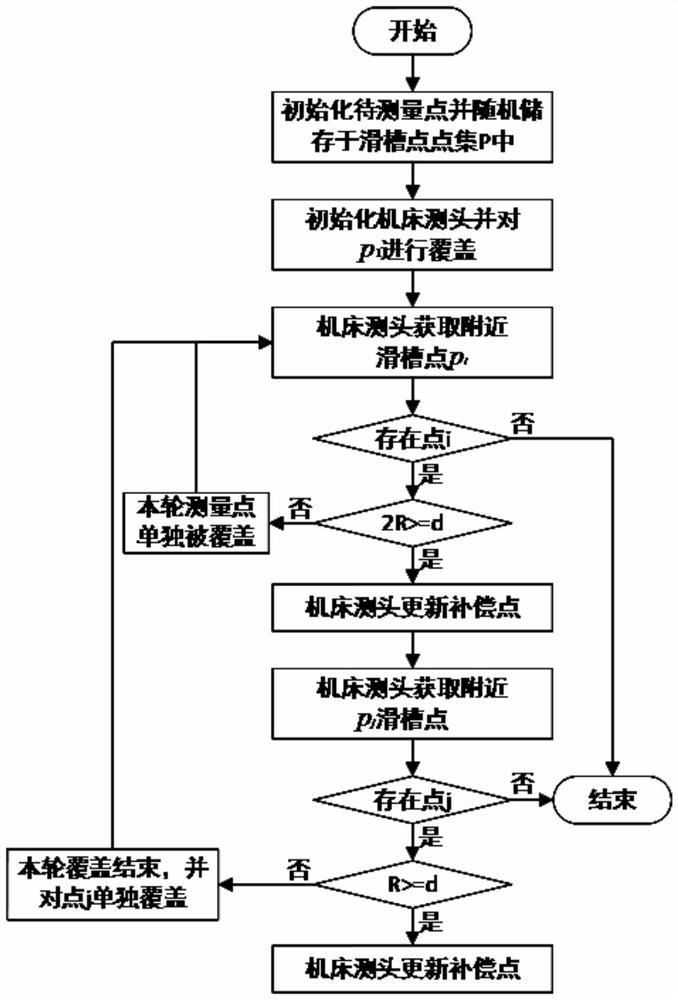

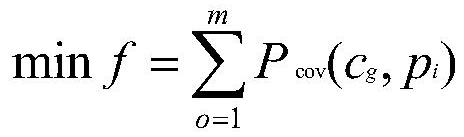

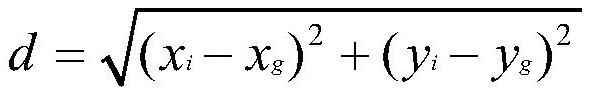

[0018] The principle of the group dynamic programming method is to decompose the multi-stage problem to be solved into several independent single-stage problems, and then subdivide these single-stage problems into several interrelated sub-problems, solve these sub-problems, and finally summarize get a global solution.

[0019] Renishaw applies a high-precision sensor to the machine tool probe. The machine tool probe consists of two parts: the probe and the receiver, which are optically transmitted by infrared rays. When the machine tool touches the workpiece, the receiver receives the touch information of the probe and feeds it back to the machine tool system, and completes the error measurement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com