Direct-reading density pipe

A direct-reading, density-based technology, applied to measuring devices, instruments, scientific instruments, etc., can solve the problems of small solid measurement, low measurement accuracy, and harsh environmental conditions, so as to guarantee test results and measurement accuracy High, reduce the effect of operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail in conjunction with specific inventions below.

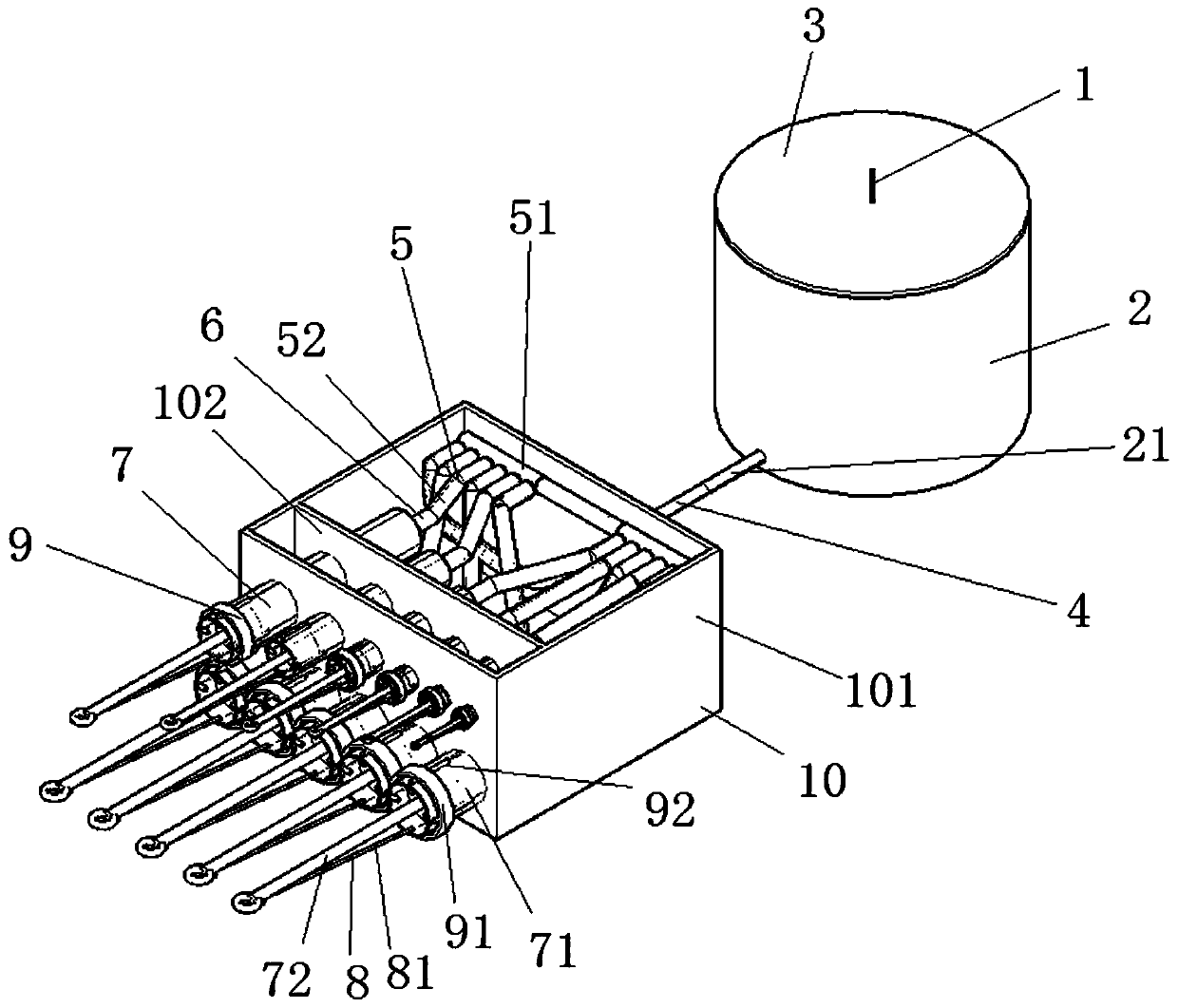

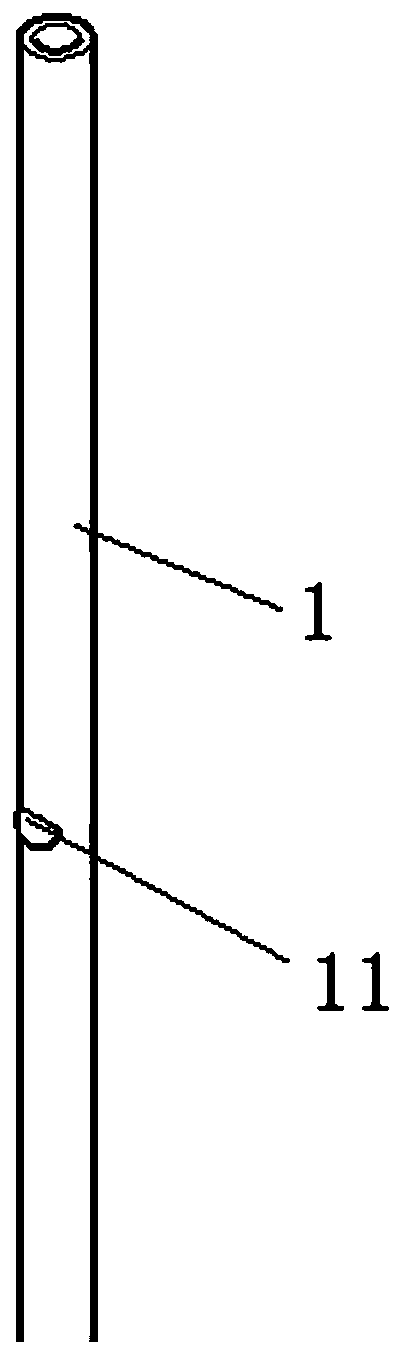

[0035] A direct-reading density tube, combined with Figure 1 to Figure 11 As shown, it includes a sample detection tube 2 , a top cover plate 3 , a volume displacement device 7 and a transparent capillary 1 .

[0036] The sample detection tube 2 has scales, is transparent, and is a transparent cylinder with upper and lower equal diameters for containing media, and samples can be put into the sample detection tube 2 .

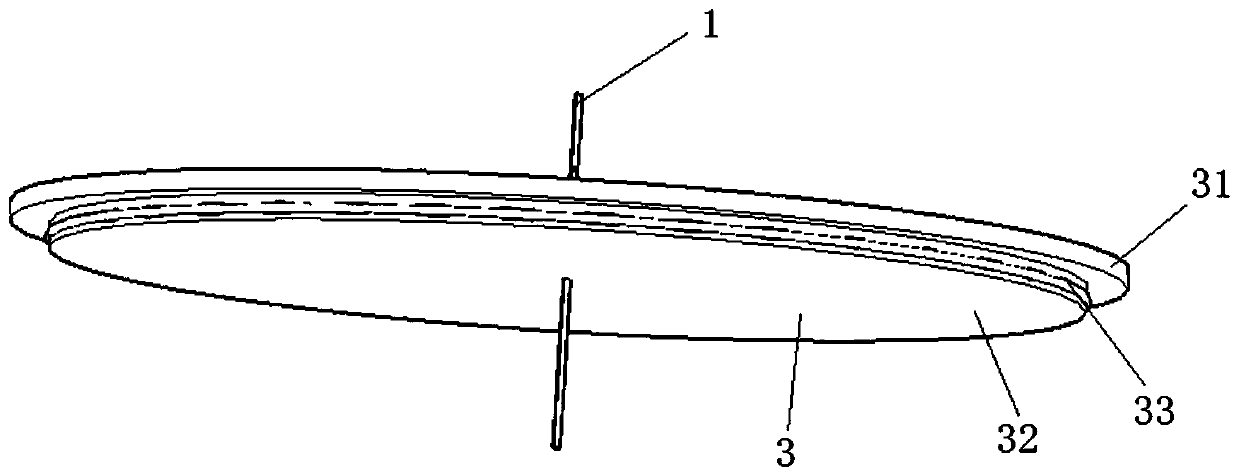

[0037] The top cover plate 3 is hermetically arranged on the top of the sample detection tube 2 and is a detachable structure for ensuring the internal pressure of the sample detection tube 2 . The top cover 3 is a cylindrical two-stage stepped transparent thin plate, and the top cover 3 includes a first transparent thin plate 31 and a second transparent thin plate 32 . The first transparent thin plate 31 is covered on the top of the sample detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com