Sensor circuit applied on range hood and range hood

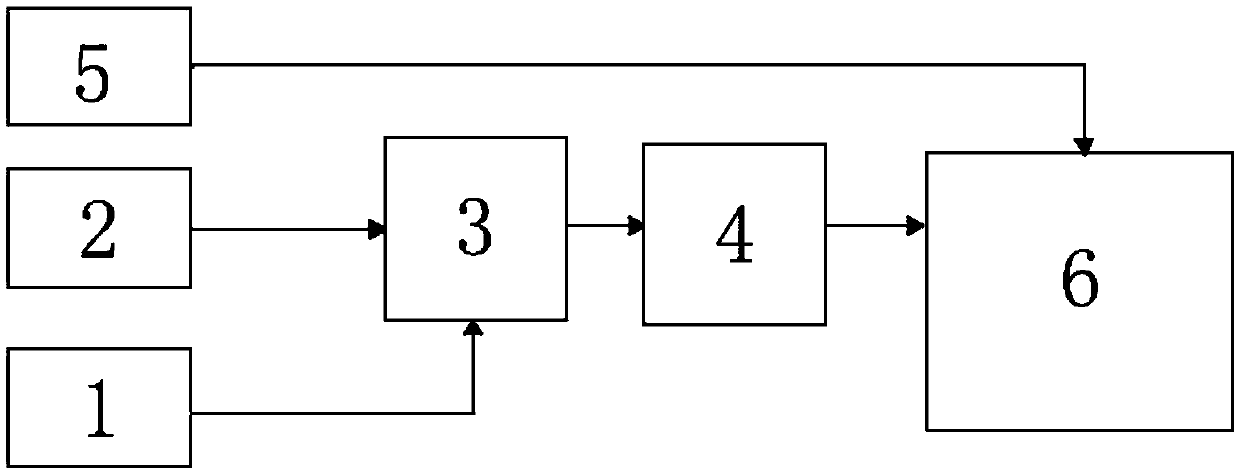

A sensor circuit, hood technology, applied in the direction of DC-coupled DC amplifiers, scientific instruments, differential amplifiers, etc., can solve the problems of affecting the detection effect, failing to reach the detection range, and the method of fixed zero adjustment being meaningless. Deviation, Accurate Response, Accurate Detection of Concentration Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

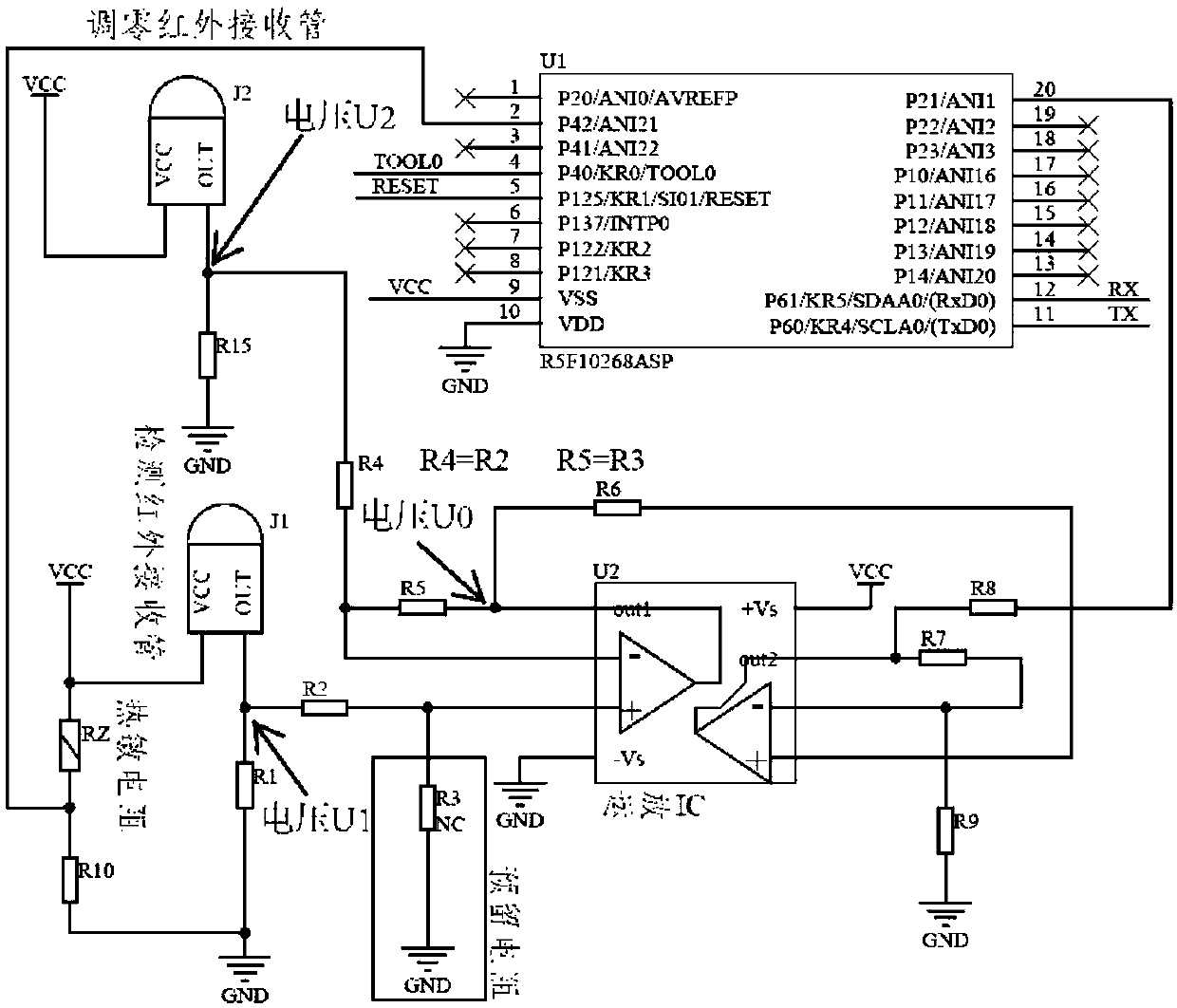

Embodiment 1

[0065] Embodiment 1 provides a sensor circuit applied to a smoke machine, such as image 3 As shown, it includes a zero-adjusting infrared receiving tube J2, a fourth resistor R4, a fifteenth resistor R15, a detecting infrared receiving tube J1, a second resistor R2, a first resistor R1, a secondary differential amplifier circuit, and a sixth resistor R6 , fifth resistor R5, third resistor R3, seventh resistor R7, ninth resistor R9, eighth resistor R8, thermistor RZ, tenth resistor R10, chip U1, programming module, serial communication module CN2, tenth Three resistors R13, fourteenth resistor R14, first capacitor C1, second capacitor C2;

[0066] One end of the zero-adjusting infrared receiving tube J2 is connected to the power supply, one of the other ends is connected to the secondary differential amplifier circuit through the fourth resistor R4, and the other is grounded through the fifteenth resistor R15;

[0067] One end of the detection infrared receiving tube J1 is co...

Embodiment 2

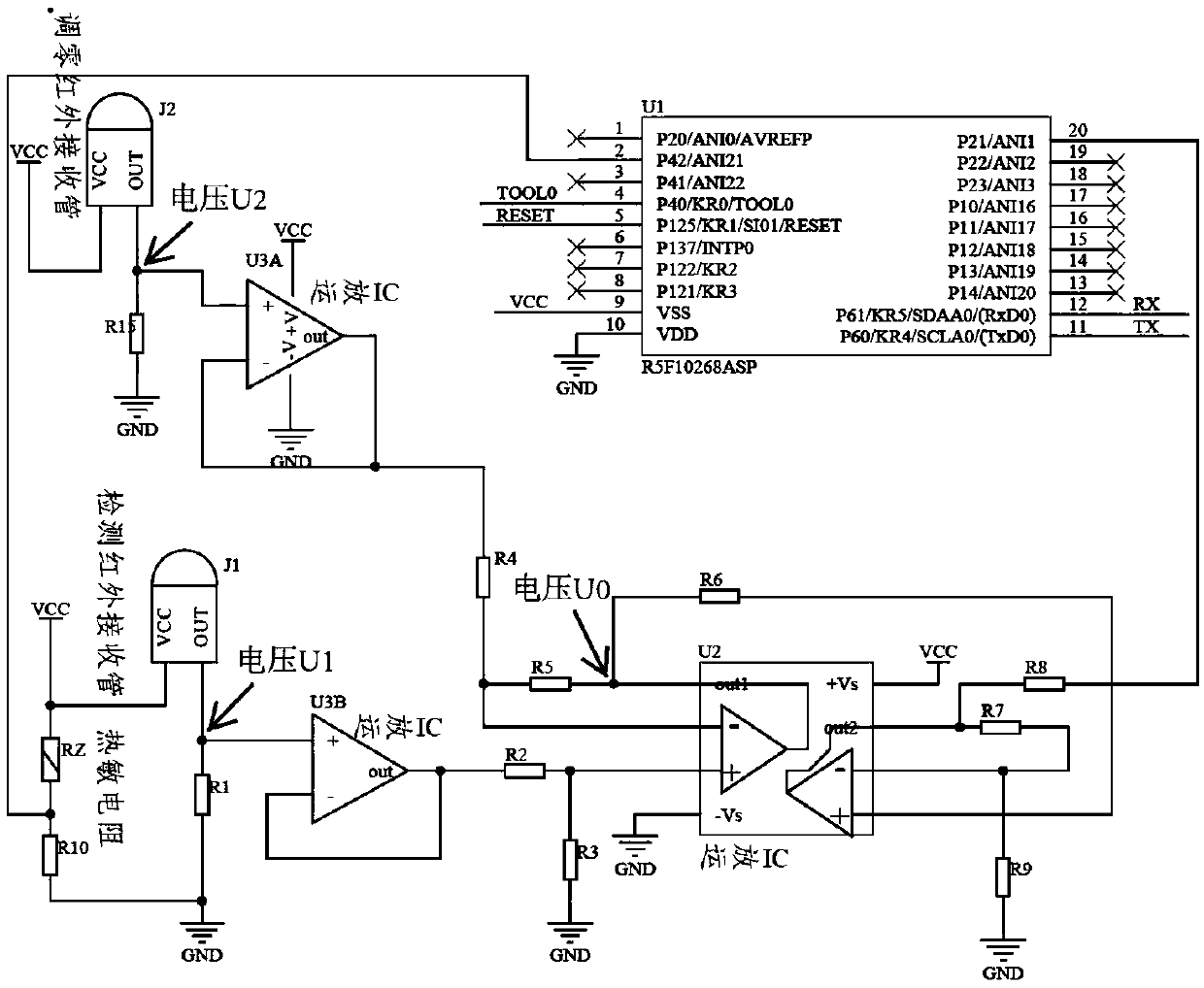

[0080] Embodiment 2 provides a sensor circuit applied to a smoke machine, such as Figure 4 As shown, it includes a zero-adjusting infrared receiving tube J2, a fourth resistor R4, a fifteenth resistor R15, a detecting infrared receiving tube J1, a second resistor R2, a first resistor R1, a secondary differential amplifier circuit, and a sixth resistor R6 , the fifth resistor R5, the third resistor R3, the seventh resistor R7, the ninth resistor R9, the eighth resistor R8, the voltage follower U3A, the voltage follower U3B, the thermistor RZ, the tenth resistor R10, the chip U1, the burner Recording module, serial port communication module CN2, thirteenth resistor R13, fourteenth resistor R14, first capacitor C1, second capacitor C2;

[0081] One end of the zero-adjusting infrared receiving tube J2 is connected to the power supply, one of the other ends is connected to the secondary differential amplifier circuit through the voltage follower U3A and the fourth resistor R4, and...

Embodiment 3

[0095] Embodiment 1 provides a sensor circuit applied to a smoke machine, such as Figure 5 As shown, it includes a zero-adjusting infrared receiving tube J2, a fourth resistor R4, a fifteenth resistor R15, a detection infrared receiving tube J1, a second resistor R2, a first resistor R1, a secondary conventional amplifier circuit, a differential amplifier circuit, Fourth resistor R4, third resistor R3, sixth resistor R6, fifth resistor R5, eighth resistor R8, thermistor RZ, tenth resistor R10, chip U1, programming module, serial port communication module CN2, thirteenth resistor Resistor R13, fourteenth resistor R14, first capacitor C1, second capacitor C2;

[0096] One end of the zero-adjusting infrared receiving tube J2 is connected to the power supply, one of the other ends is connected to the secondary differential amplifier circuit through the fourth resistor R4, and the other is grounded through the fifteenth resistor R15;

[0097] One end of the detection infrared rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com