Pre-lithiation preparation method of lithium ion battery pasting agent and production and application

A lithium-ion battery and adhesive technology, applied in the field of lithium-ion batteries, can solve problems such as safety hazards, and achieve the effects of increasing cycle life, easy operation, and improving first efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0029] A lithium-ion battery negative electrode binder is used for silicon-based negative electrode materials, including:

[0030] (1) Silica material

[0031] (2) Binder lithium polyacrylate [CH 2 CH] n COOLi 10 wt%

[0032] (3) Conductive agent SP 10 wt%,

[0033] Mix the silicon-oxygen material with a certain proportion of binder to make lithium polyacrylate [CH 2 CH] n COOLi and conductive agent SP were coated to prepare a button half-cell, which was assembled into a battery and left to stand for 24 h.

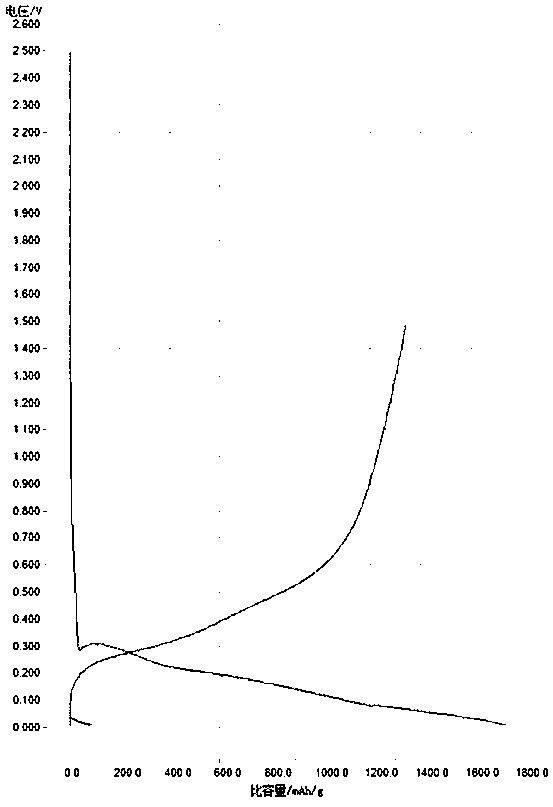

[0034] Under the condition that the ambient temperature is 25°C, the charge and discharge test is carried out using the Newwell battery test system, and the first charge and discharge effect is obtained as follows: figure 2 As shown, the first effect is 71.8%, and it can be seen that the first effect has been significantly improved.

Embodiment 3

[0036] A lithium-ion battery negative electrode binder is used for silicon-based negative electrode materials, including:

[0037] (1) Silica material

[0038] (2) Binder lithium polyacrylate [CH 2 CH] n COOLi 5 wt%

[0039] (3) Conductive agent SP 5 wt%,

[0040] Mix the silicon-oxygen material with a certain proportion of binder lithium polyacrylate [CH 2 CH] n COOLi and conductive agent SP were coated to prepare a button half-cell, which was assembled into a battery and left to stand for 24 h.

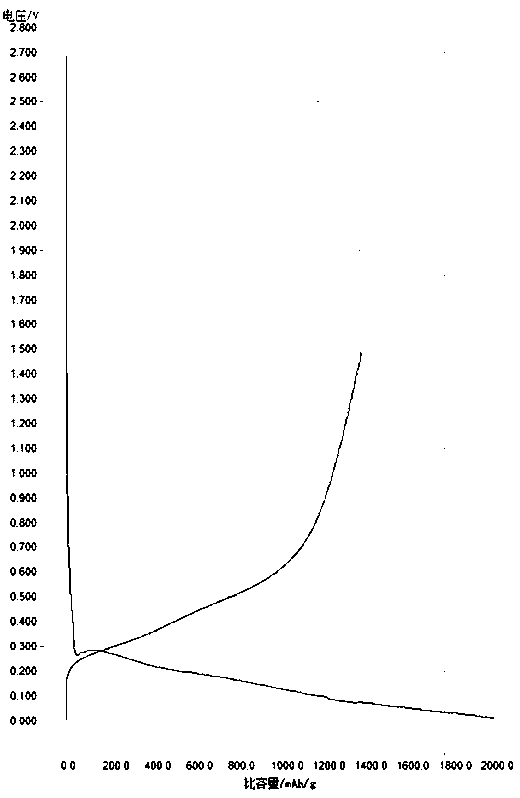

[0041] Under the condition that the ambient temperature is 25°C, the charge and discharge test is carried out using the Newwell battery test system, and the first charge and discharge effect is obtained as follows: image 3 As shown, the first effect is 73.2%, and it can be seen that the first effect has been significantly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com