Vibration separation beneficiation equipment

A technology of mineral processing equipment and vibration separation, applied in the field of mineral processing, can solve the problems of small processing capacity, low recovery rate of useful minerals, large water consumption, etc., and achieve the effects of large processing capacity, improved recovery rate, and high recovery rate of useful minerals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention. All similar structures and similar changes of the present invention should be included in the scope of protection of the present invention. The commas in all represent the relationship between and, and the English letters in the present invention are case-sensitive.

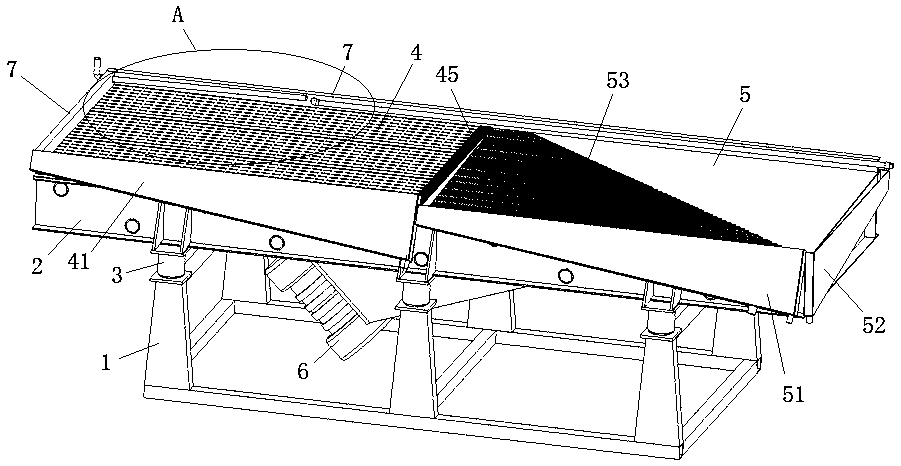

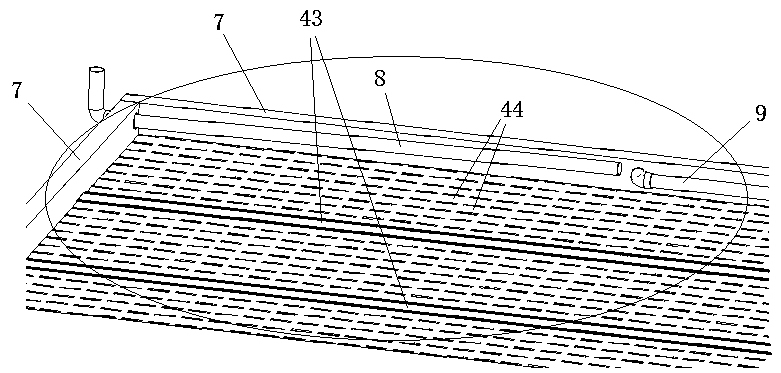

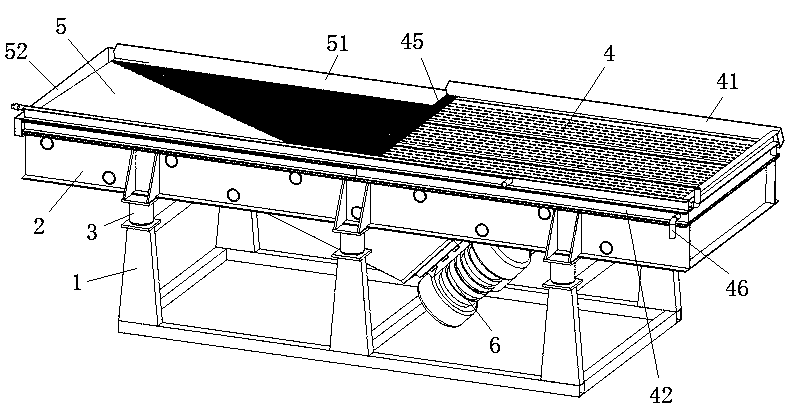

[0022] Such as Figure 1-3 As shown, a vibration separation mineral processing equipment provided by the first embodiment of the present invention includes a machine base 1 and a mineral processing bed, and is characterized in that: the machine base 1 is provided with a vibrating frame 2 and a plurality of exciting springs 3;

[0023] Each excitation spring 3 is divided into two groups, and each group includes at least two excitation springs, one group of excitation springs is arranged on the left part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com