Buckling constrained beam and column self-reset joint based on steel-shape memory alloy (SMA) plate set element and assembly method

A buckling restraint and self-resetting technology, applied to building components, building types, buildings, etc., can solve the problems of increasing energy consumption capacity and complex design, and achieve the effects of improving energy consumption capacity, simple and convenient installation, and recoverable deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

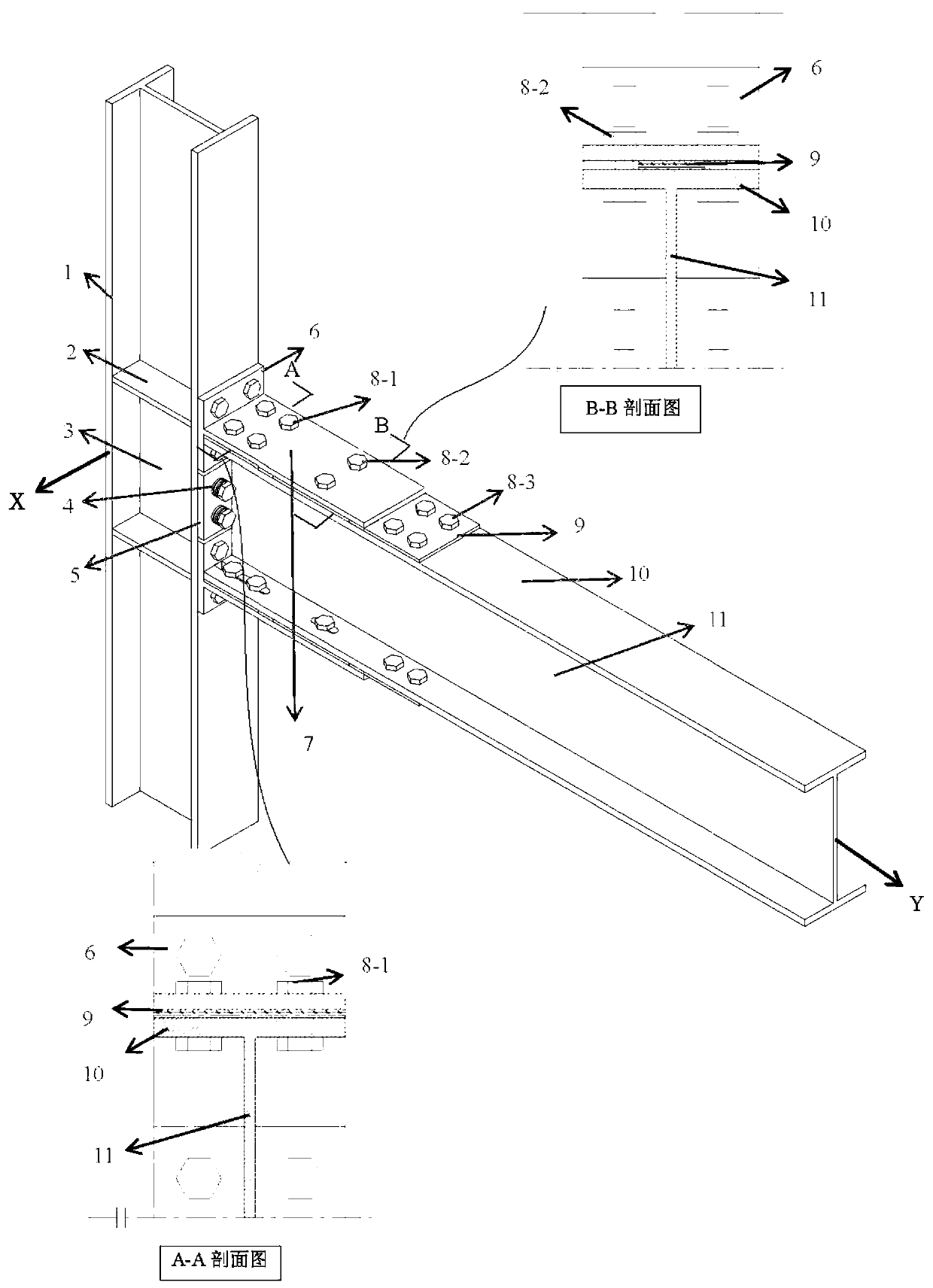

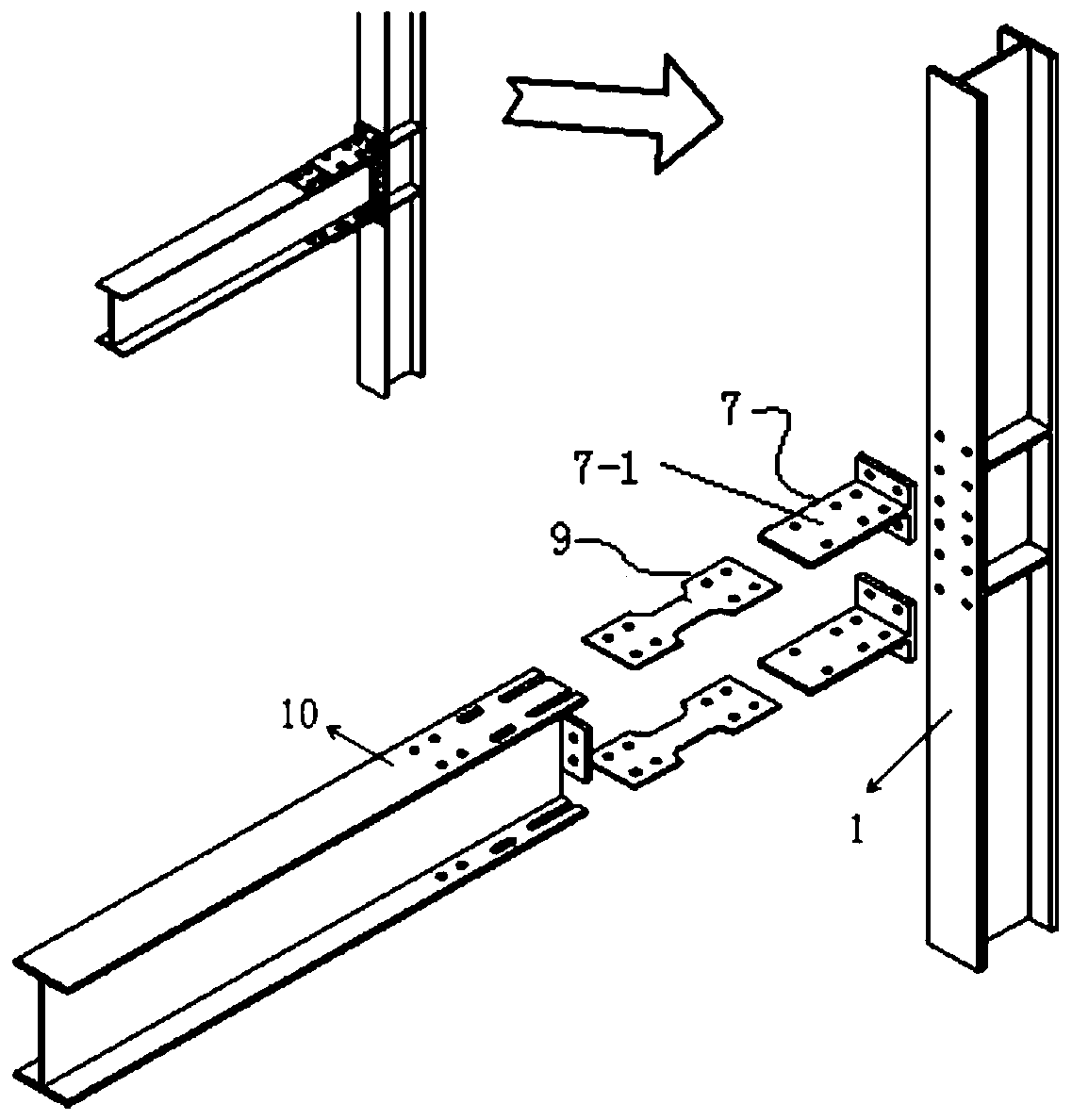

[0040] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the accompanying drawings and specific implementation cases.

[0041] The present invention provides a buckling restrained beam-column self-resetting node based on steel-SMA plate group elements, including: 1. I-shaped steel column 2, I-shaped steel beam 3, T-shaped steel plate 4, SMA bone-shaped connecting plate 5, SMA Disc spring 6, rectangular end plate 7, column stiffener; friction type high-strength bolt.

[0042] This self-resetting node includes the selected beam-column connection node area in the structure, which includes I-shaped steel columns with stiffeners, I-shaped steel beams, T-shaped steel plates, SMA bone-shaped connecting plates, SMA disc springs, rectangular End plates and friction-type high-strength bolts. The three sides of the column stiffener are fillet-welded on the I-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com