Efficient energy-consumption self-resetting anti-buckling support

An anti-buckling bracing and self-resetting technology, applied in earthquake resistance, building type, building, etc., can solve problems such as poor self-resetting bracing energy dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

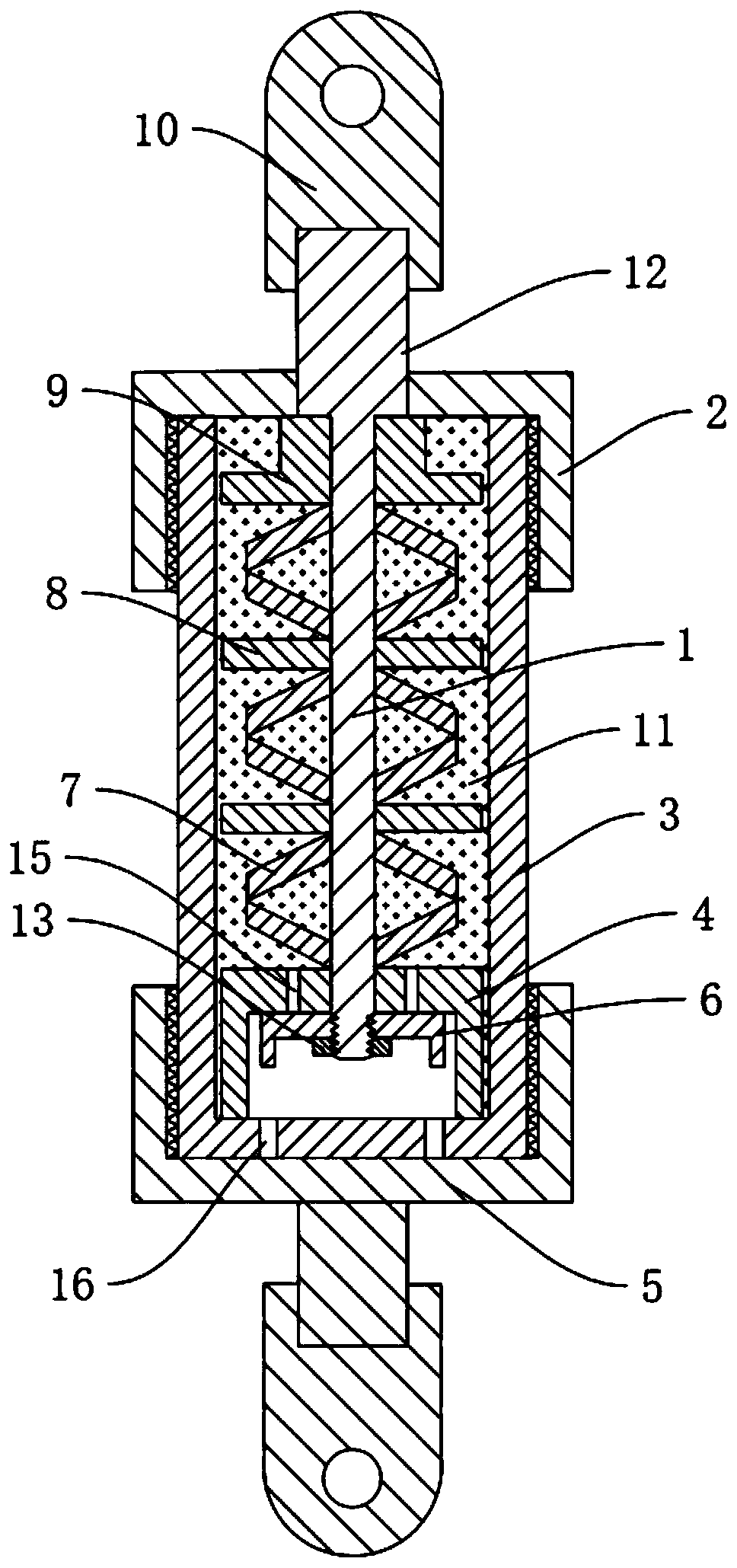

[0028] Embodiment 1: as Figure 1 to Figure 3 As shown, a high-efficiency energy-consuming self-resetting anti-buckling support proposed by the present invention includes a piston rod 1, an upper sealing cylinder 2, a sealing cylinder 3, and a lower sealing connector 5. The sealing cylinder 3 is filled with a damping material 11, The damping material 11 can be various types of damping materials such as viscous damping material and damping oil; the sealed cylinder body 3 can be a sealed integral type, a hole reserved at the bottom or a split type; the upper sealing cylinder 2 and the lower sealing connector 5 are separately arranged on Seal both ends of the cylinder body 3, the piston rod 1 is passed through the upper sealing cylinder 2; the upper connecting piece 10 is fixedly connected to the piston rod 1, and the upper connecting piece 10 and the lower sealing connecting piece 5 are respectively connected to the end of the piston rod 1 The bottom of the sealed cylinder 3 is ...

Embodiment 2

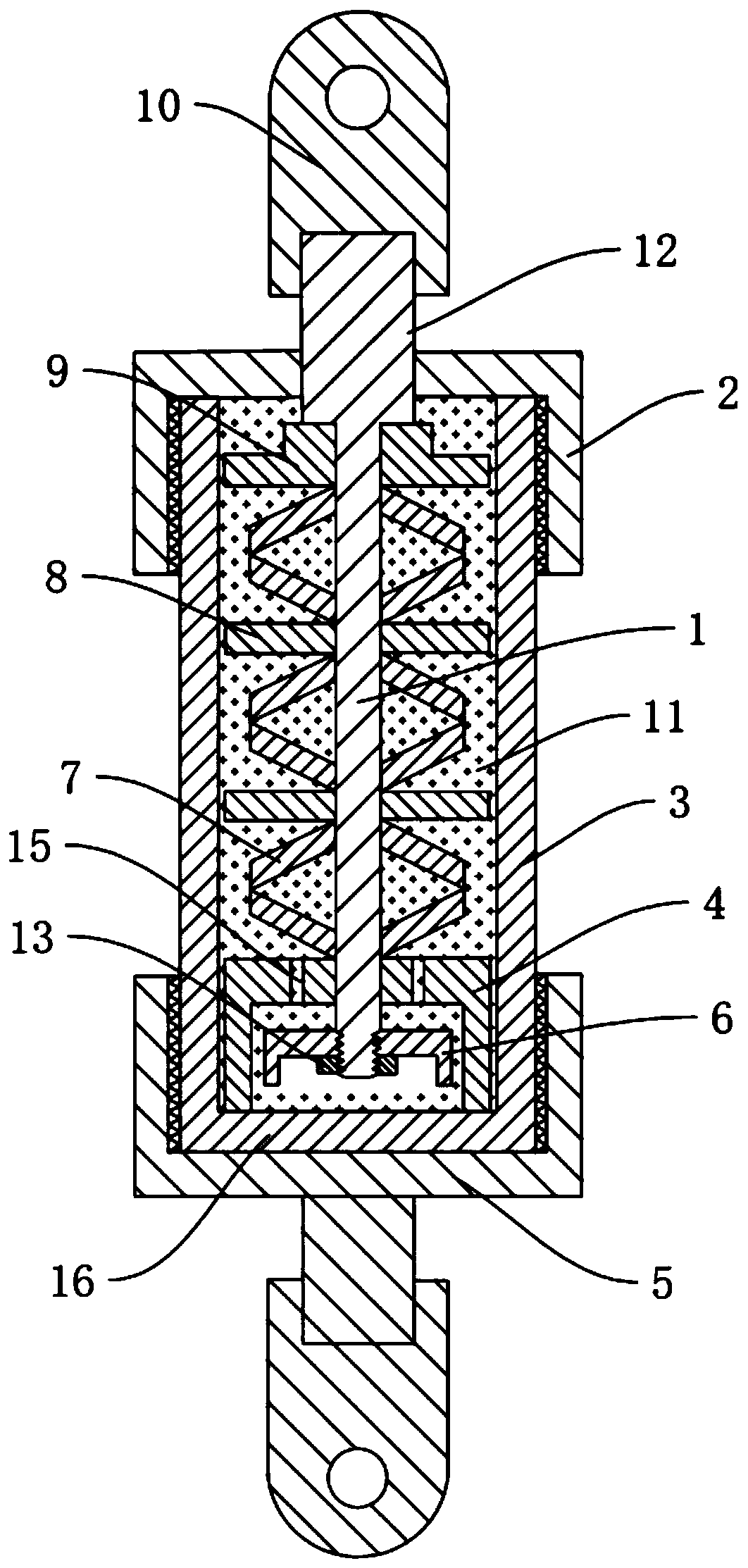

[0033] Embodiment 2, differs from Embodiment 1 in that: as Figure 4 As shown, the sealing energy-dissipating end plate 9 of the upper oil storage tank and the edges of the energy-dissipating partition 8 are all set as wide flange structures. The energy-dissipating end plate 9 sealed by the upper oil storage tank and the edge of the energy-dissipating partition 8 have a wide-wing structure, so that the shear area between the sealed cylinder 3 and the damping material 11 is significantly increased, and the internal parts of the component are relatively small to the damping material 11. The shearing and extrusion effects significantly improved the energy dissipation capacity of the support members.

Embodiment 3

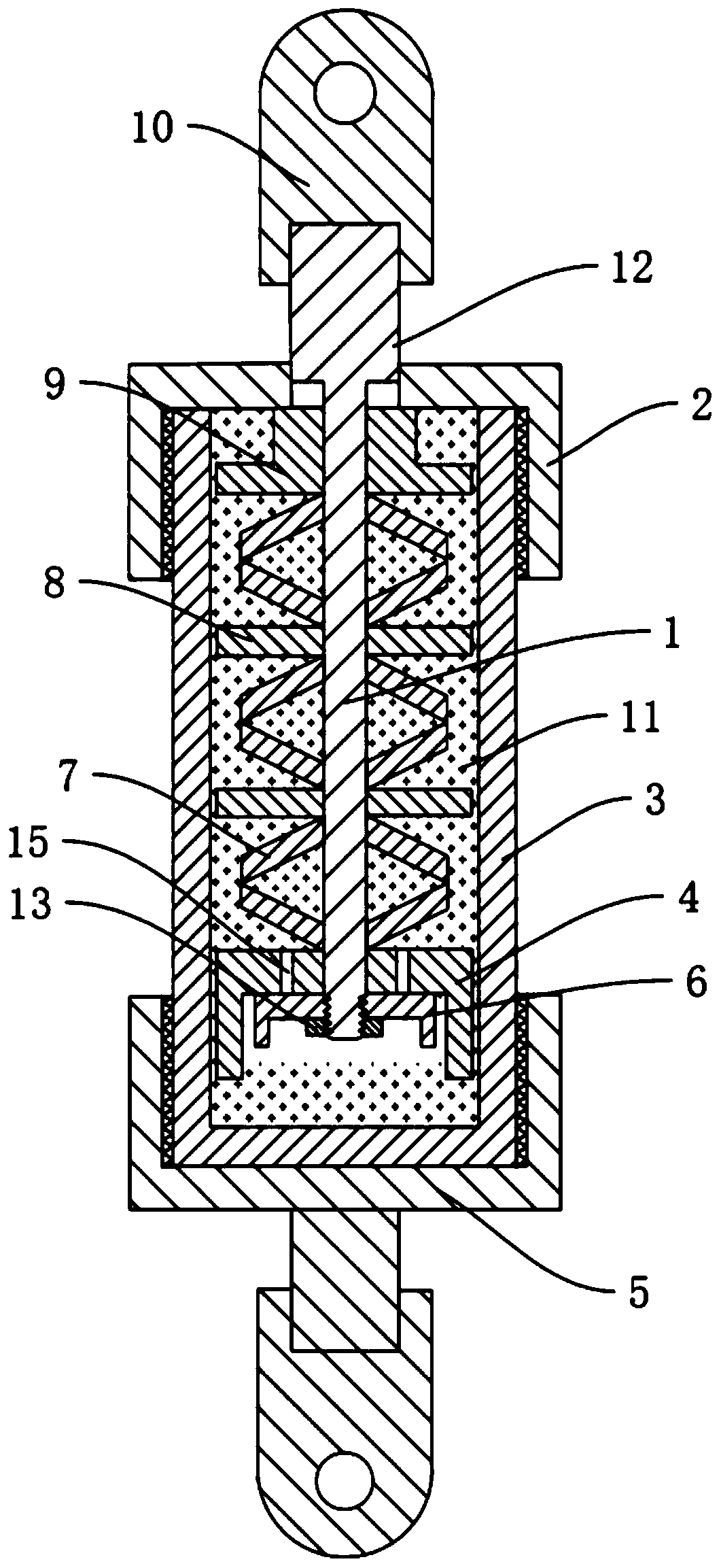

[0034] Embodiment 3, differs from Embodiment 1 in that: as Figure 5 As shown, damping holes 14 for the circulation of damping material 11 are provided on the sealed energy-dissipating end plate 9 of the upper oil storage tank, the energy-dissipating partition 8 and the limiting energy-dissipating end cylinder 4 of the lower oil storage tank, and the sealed energy-consuming end of the upper oil storage tank The plate 9 , the energy-dissipating partition 8 and the limit energy-dissipating end cylinder 4 of the lower oil storage tank are attached to the inner wall of the sealed cylinder 3 or leave a gap with the sealed cylinder 3 . The damping hole 14 facilitates the circulation of the damping material 11 between the sealed energy-dissipating end plate 9 of the upper oil storage tank, the energy-dissipating partition 8 and the limiting energy-dissipating end cylinder 4 of the lower oil storage tank, which plays a damping role and improves the energy consumption of the supporting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com