Automatic speed changer electric hydraulic cooling lubrication system and control system thereof

An automatic transmission, cooling and lubrication technology, applied in the direction of gear lubrication/cooling, transmission parts, belts/chains/gears, etc., can solve the problems of high cost and large space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

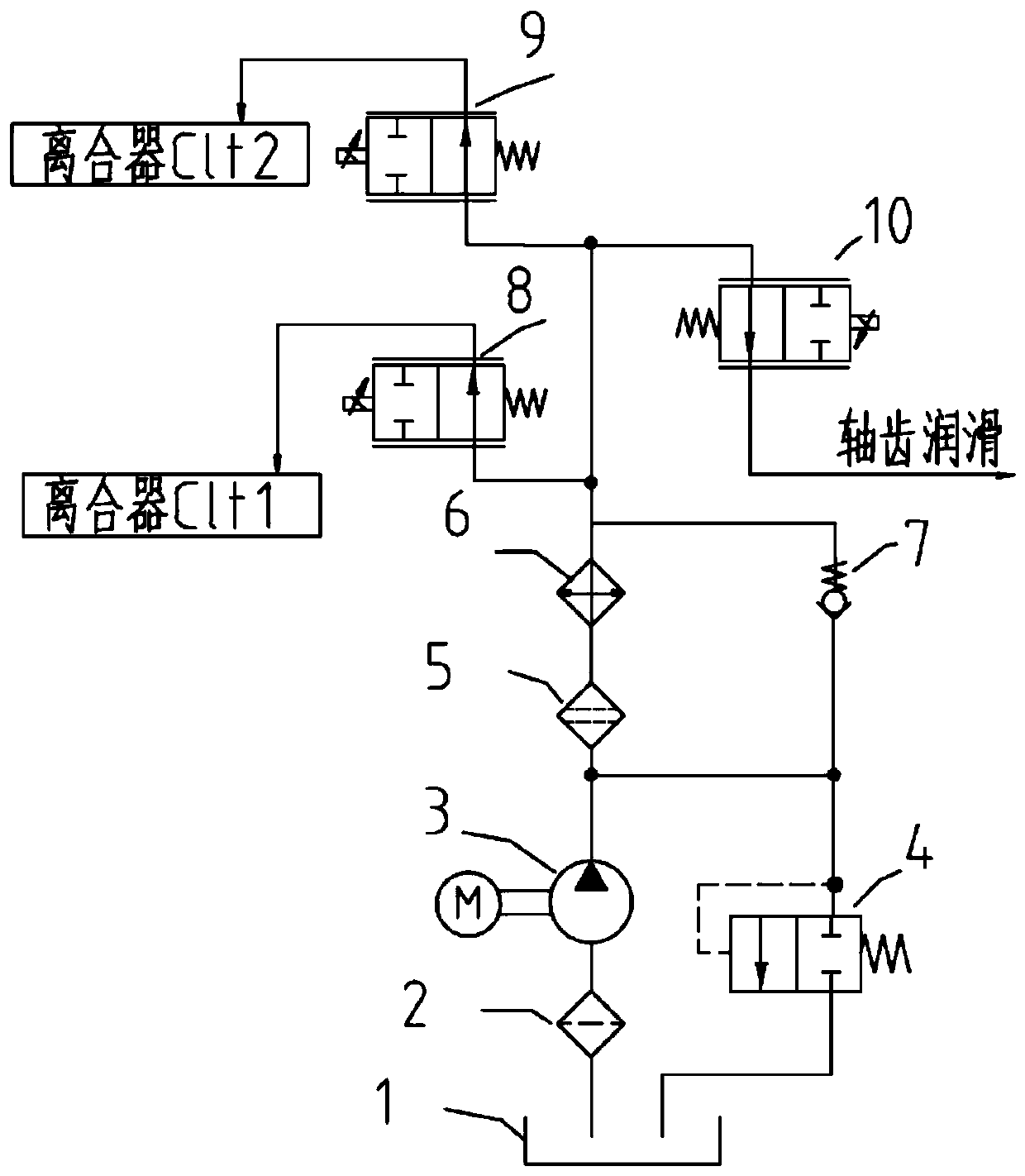

[0057] This embodiment is used in a dual-clutch automatic transmission with two lubricating oil channels independent of each other and a wet clutch, in which the shaft-tooth flow regulating device adopts the lubrication and cooling system of the shaft-tooth proportional flow control valve.

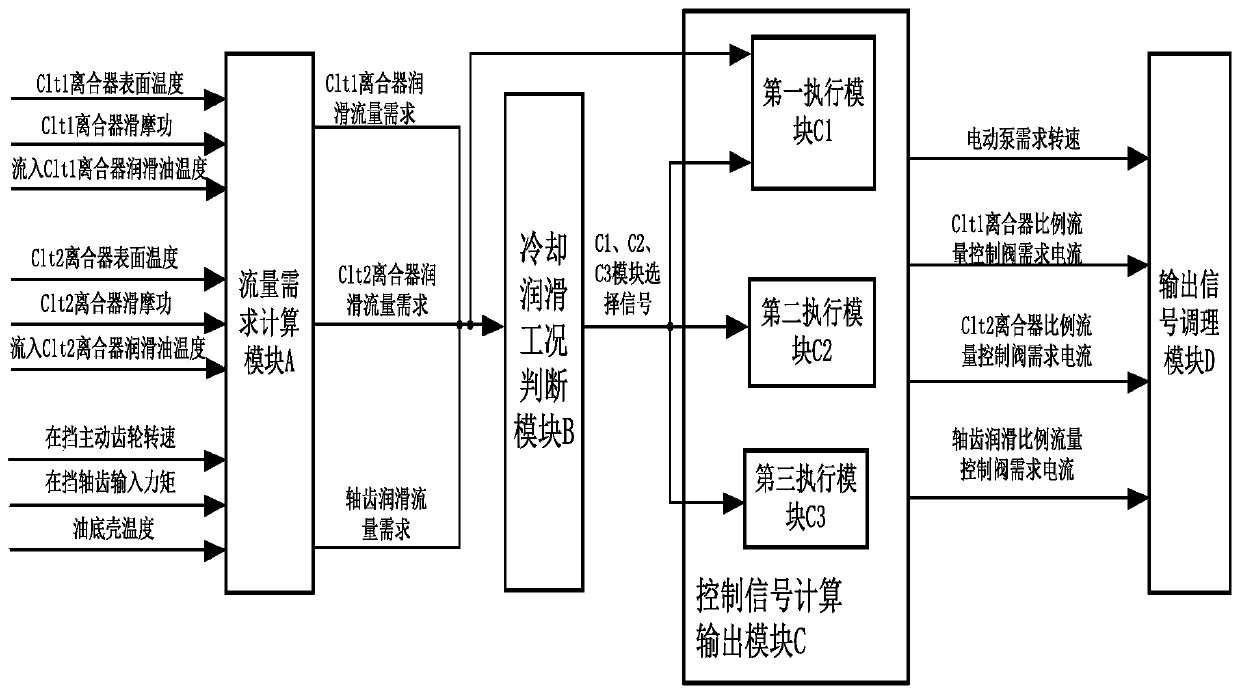

[0058] Such as figure 1 As shown, the electro-hydraulic cooling and lubricating system of the automatic transmission of the present invention includes: oil storage tank 1, oil suction filter 2, electro-hydraulic pump 3, unloading valve 4, electro-hydraulic pump outlet filter 5, cooler 6, one-way Valve 7, a first proportional flow control valve 8, a second proportional flow control valve 9 and a shaft tooth flow regulating device 10; wherein, the oil inlet of the oil suction filter 2 is connected to the oil storage tank 1, and the oil suction filter 2 The oil outlet of the electric hydraulic pump 3 is connected to the oil suction port of the electric hydraulic pump 3, and the oil outlet of ...

Embodiment 2

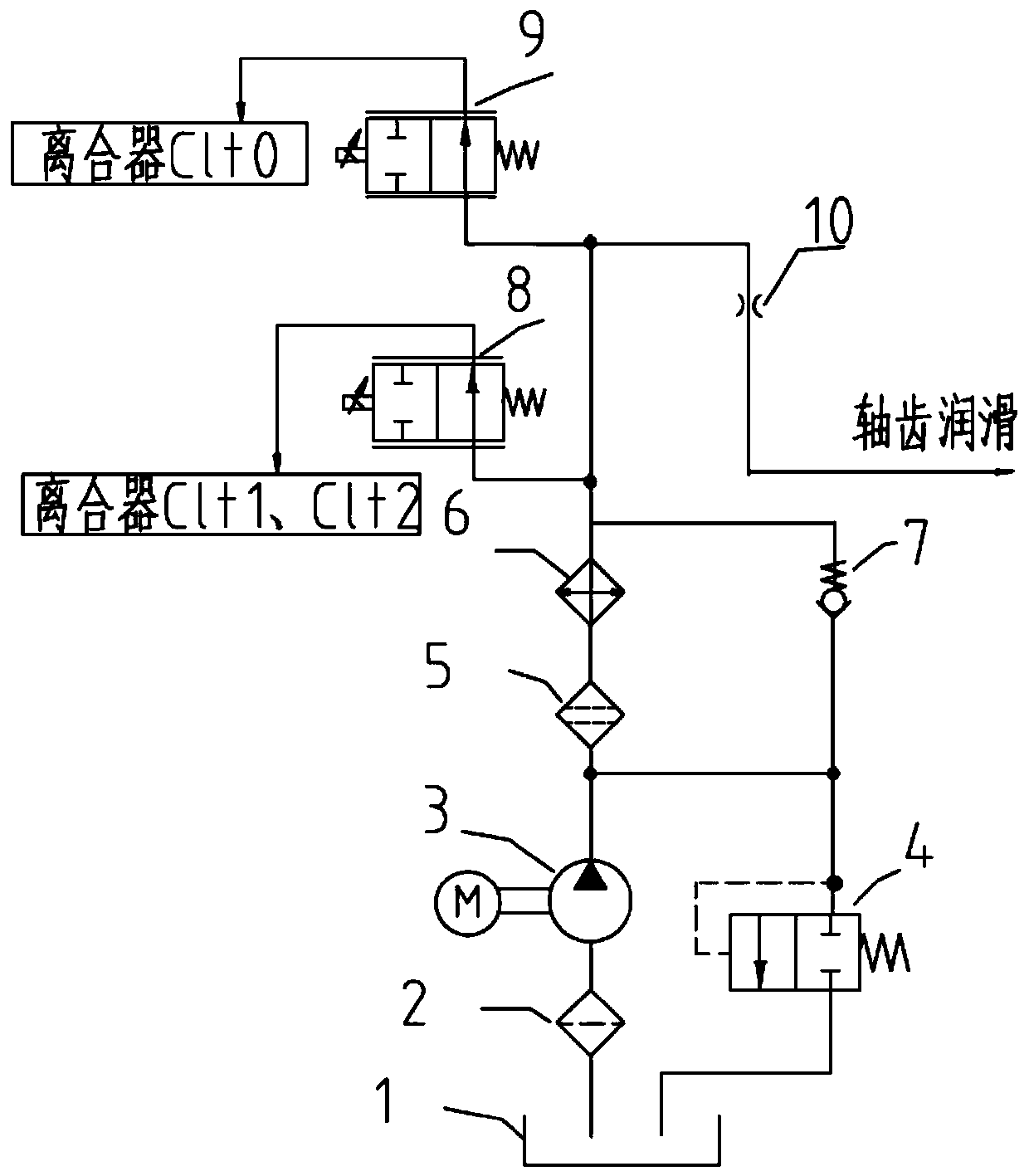

[0089] The difference between this embodiment and Embodiment 1 is that this embodiment is used for the automatic transmission lubrication system of hybrid vehicles, and the system includes three clutches, wherein clutch Clt0 is a separation clutch and has an independent lubricating oil passage; clutches Clt1, Clt2 The lubricating oil passages of the first proportional flow control valve 8 are connected in series with the lubricating oil passages of the clutches Clt1 and Clt2 to control the cooling and lubricating flow of the clutches Clt1 and Clt2; the oil outlet end of the second proportional flow control valve 9 Connect the lubricating oil channel of clutch Clt0 to control the cooling and lubricating flow of clutch Clt0. The shaft tooth flow regulating device 10 adopts a throttling hole; the diameter of the throttling hole is determined according to the lubrication flow requirement and the test calibration; in this embodiment, the diameter of the throttling hole can be set to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com