A stepping motor detection system for automobiles

A stepping motor and detection system technology, which is applied in the direction of motor generator testing, temperature measurement in the motor, measuring electricity, etc., can solve the lack of leakage and temperature detection of stepping motors, affect the service life of stepping motors, and detect system functions Single and other problems, to achieve the effect of diverse functions, reasonable structure, and expanded detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

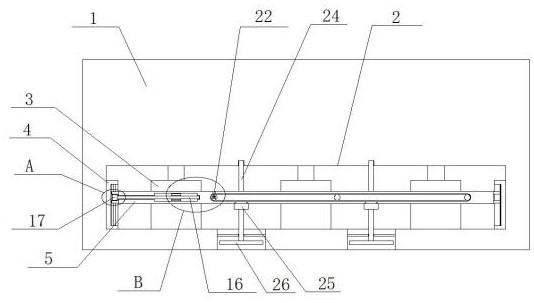

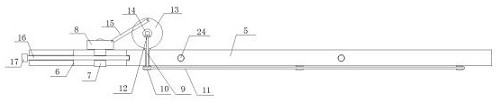

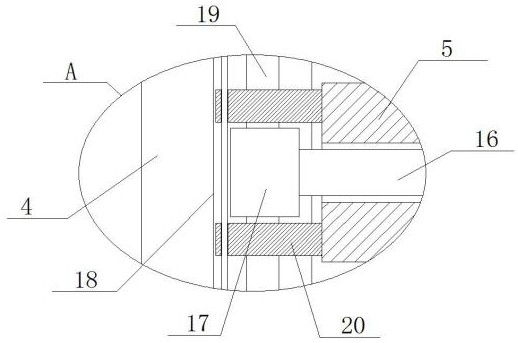

[0030] refer to Figure 1-7 , a stepper motor detection system for automobiles, including a module to be tested, a signal conditioning circuit module and a virtual instrument module, the module to be tested is connected to the signal conditioning circuit module, the signal conditioning circuit module is connected to the virtual instrument module, and the module to be tested Including stepping motor system unit, motor drive circuit unit, leakage detection unit and temperature detection unit, virtual instrument module includes data acquisition card unit and industrial computer unit, data acquisition card unit is connected with industrial computer unit, temperature detection unit includes instrument panel 1 and a plurality of temperature sensors 8, a fixed cavity 2 is provided on the instrument panel 1, and a plurality of stepping motors 3 are fixedly installed in the fixed cavity 2, and fixed plates 4 are fixedly installed on the inner walls of both sides of the fixed cavity 2. ...

Embodiment 2

[0039] refer to Figure 1-7 , further improvements have been made on the basis of Example 1:

[0040] A stepper motor detection system for automobiles, comprising a module to be tested, a signal conditioning circuit module and a virtual instrument module, the module to be tested is connected to the signal conditioning circuit module, the signal conditioning circuit module is connected to the virtual instrument module, and the module to be tested includes Stepping motor system unit, motor drive circuit unit, leakage detection unit and temperature detection unit, the virtual instrument module includes a data acquisition card unit and an industrial computer unit, the data acquisition card unit is connected to the industrial computer unit, and the temperature detection unit includes an instrument panel 1 and a plurality of temperature sensors 8, a fixed chamber 2 is provided on the instrument panel 1, and a plurality of stepping motors 3 are installed in the fixed chamber 2 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com