Pull type straw briquetting machine

A straw briquetting machine and traction-type technology, applied in the field of agricultural machinery, can solve problems such as unstable combustion performance, high soil content in products, and increased briquetting costs, and achieve increased density adjustability, flexible and reliable operation, and improved The effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

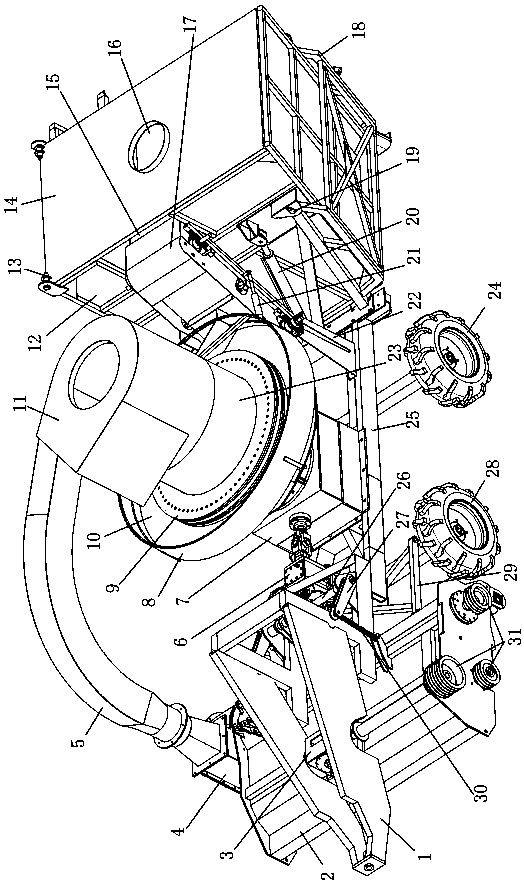

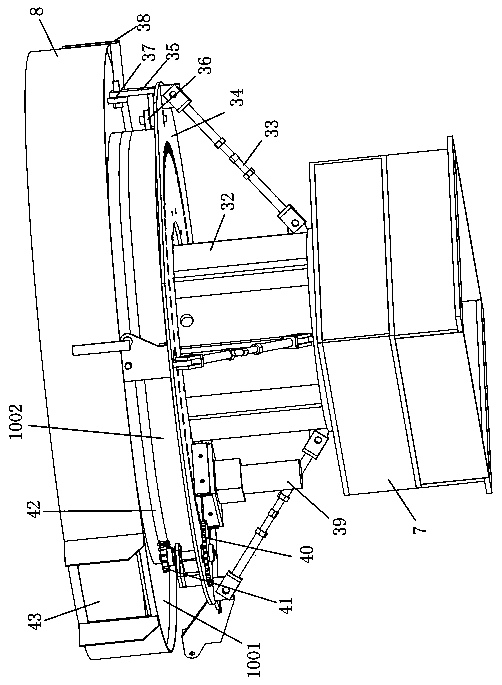

[0034] Such as Figure 1-Figure 8 As shown, the traction-type straw briquetting machine includes a frame 25, a briquetting system located on the frame 25, and a product storage bin 12 connected to the briquetting system. The bottom of the frame 25 is provided with front, Rear wheel group 28,24, the front end of frame 25 is provided with traction suspension frame 1, and the front portion of frame 25 is connected with the stalk picking-up feeding system that communicates with briquetting system, and the discharge end of described briquetting system is connected with product. A material hoist is provided between the feeding ports of the storage bin 12 .

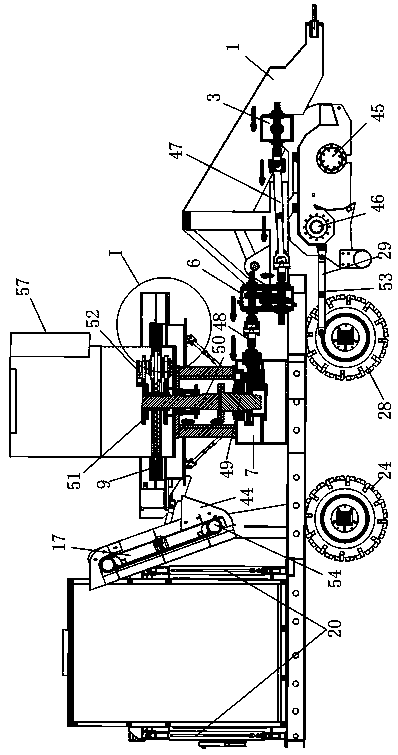

[0035] Among them, see figure 2 , the briquetting system includes a granulation gearbox 7 fixed on the upper surface of the frame 25, a support cylinder 32 fixed on the top of the granulation gearbox 7, a granulation chamber 23 fixed on the top of the support cylinder 32, a The pressure roller mechanism in the chamber 23 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com