A method for preparing ellagic acid by gallnut, the prepared ellagic acid and its application

A technology of ellagic acid and gallnut, applied in the field of ellagic acid, can solve problems such as expensive instruments, high industrial production costs, and complexity, and achieve the effects of simple operation, environmentally friendly preparation process, and good yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 of the present invention is: a method for preparing ellagic acid from Galla gall, comprising the following steps:

[0026] (1) Mix 20 g of commercial gallnut powder with 200 mL of deionized water, pour it into a beaker, and stir at room temperature for 2 h.

[0027] (2) Filtrate with a vacuum pump and discard the residue.

[0028] (3) Pour the extract obtained in step (2) into a conical flask, add 1.5 g of sodium persulfate and 1 g of sodium bicarbonate, adjust the pH to 8.5 with 30% sodium hydroxide, and react for 16 hours.

[0029] (4) Adjust the pH to about 4 with concentrated hydrochloric acid, wash with water, centrifuge at 10,000 rpm for 5 minutes, and take the precipitate.

[0030] (5) Obtain ellagic acid solid after drying.

[0031] (6) The above experimental operation was repeated 3 times, and the yields were calculated respectively.

Embodiment 1

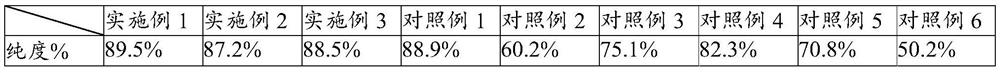

[0038] The raw material of embodiment 1 and comparative example 1, product weight information are as shown in table 1 below:

[0039] Table 1

[0040]

[0041] It can be seen from the above table 1 that the scheme of the embodiment of the present invention cleverly replaces the traditional solid-liquid separation filtration method after the acid precipitation process with centrifugation, which avoids that the product sticks to the filter membrane and is difficult to remove when the precipitation is filtered. , which can increase the yield by more than 10%.

Embodiment 2

[0042] Embodiment 2 of the present invention is: a method for preparing ellagic acid by using Galla chinensis, which differs from Embodiment 1 only in that the amount of sodium persulfate added is 1 g, and the mass of sodium bicarbonate is 0.67 g.

[0043] The yield calculated by weighing is 44.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com