Transcritical CO2 air source system adopting phase change energy storage

A phase change energy storage and transcritical technology, which is applied in the field of transcritical CO2 air source system, can solve the problems of phase change material matrix leakage, great impact on system performance, and degradation of thermophysical properties, so as to increase evaporation pressure and improve system efficiency. Efficiency, effect of reducing circulation volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention will be further described and illustrated through specific embodiments below, so that those skilled in the art can implement it with reference to the description.

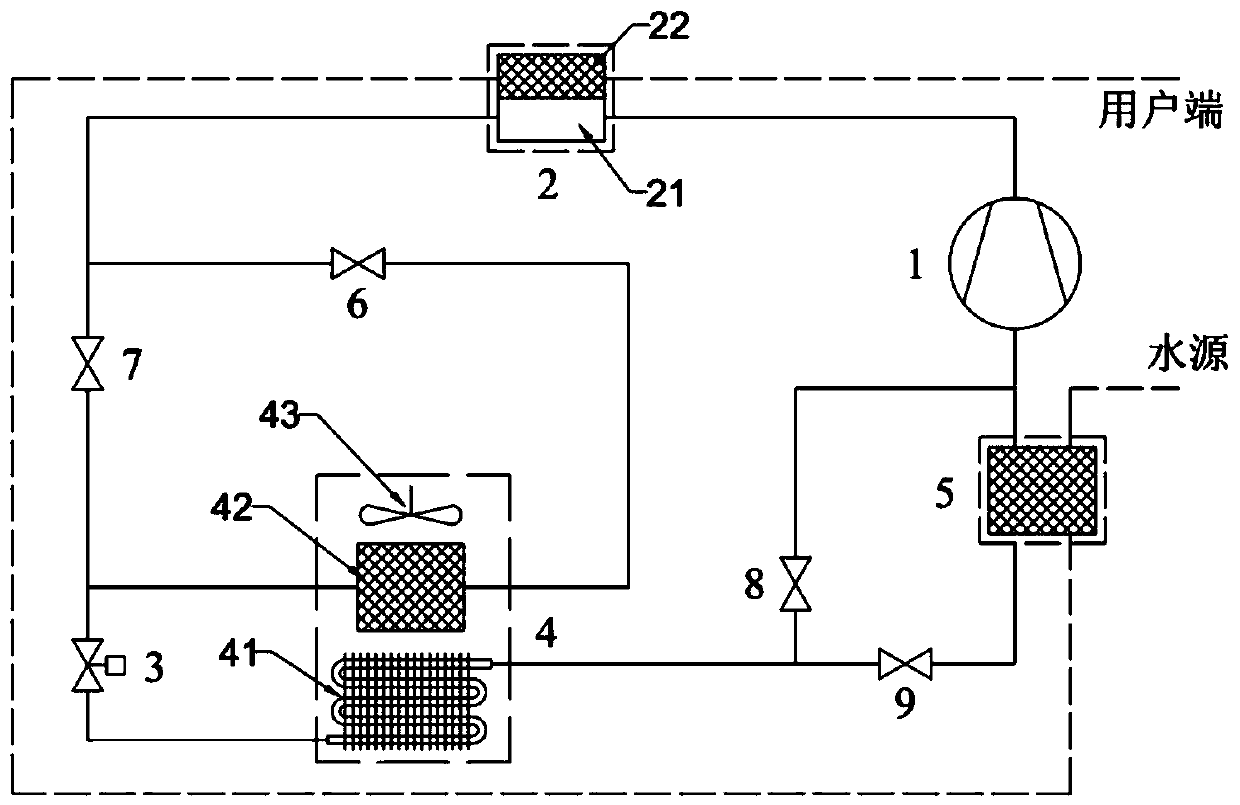

[0032] Such as figure 1 As shown, the transcritical CO using phase change energy storage described in the present invention 2 The air source system includes a compressor 1 , a first thermal storage module 2 , a throttling device 3 , a second thermal storage module 4 and a cold storage module 5 . In this embodiment, the throttling device 3 adopts an electronic expansion valve.

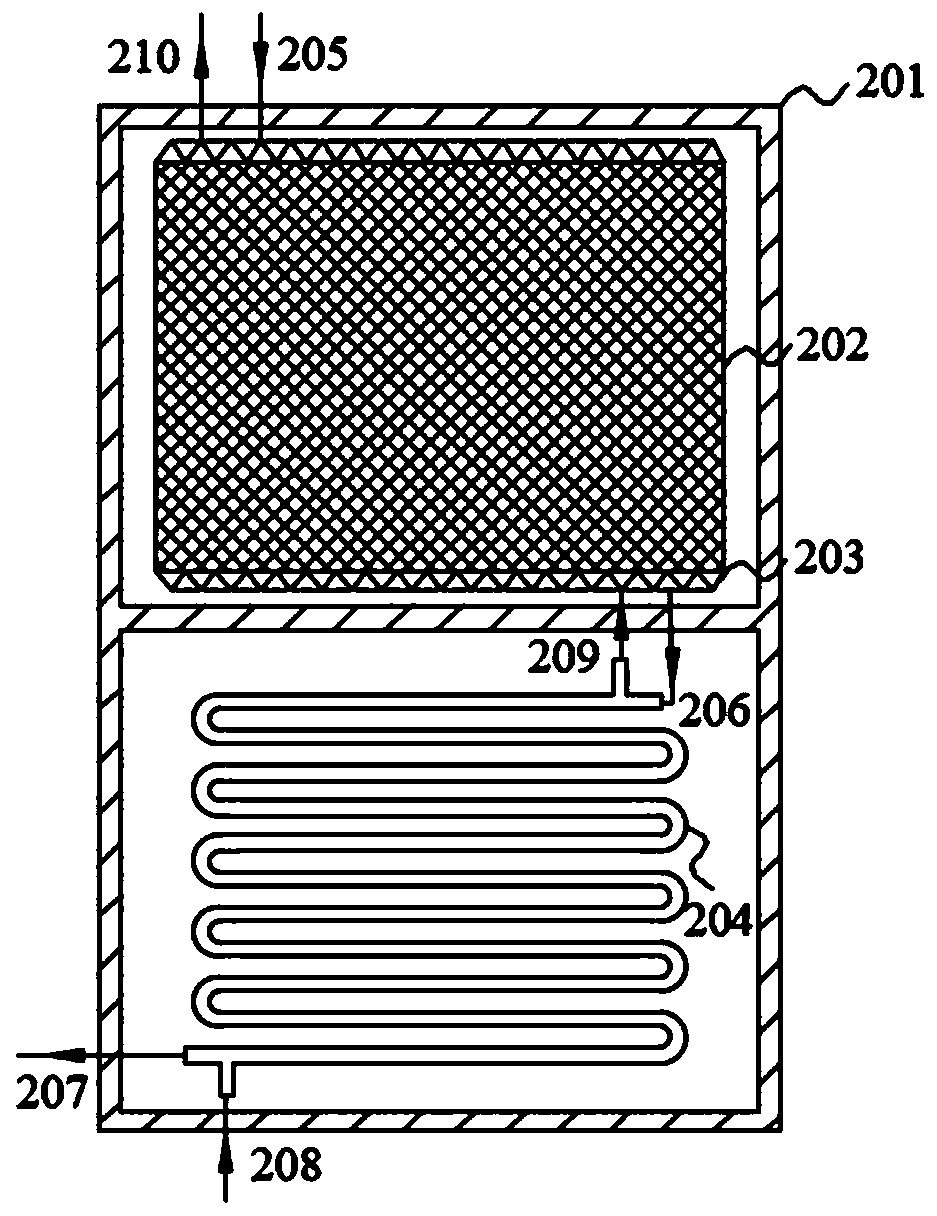

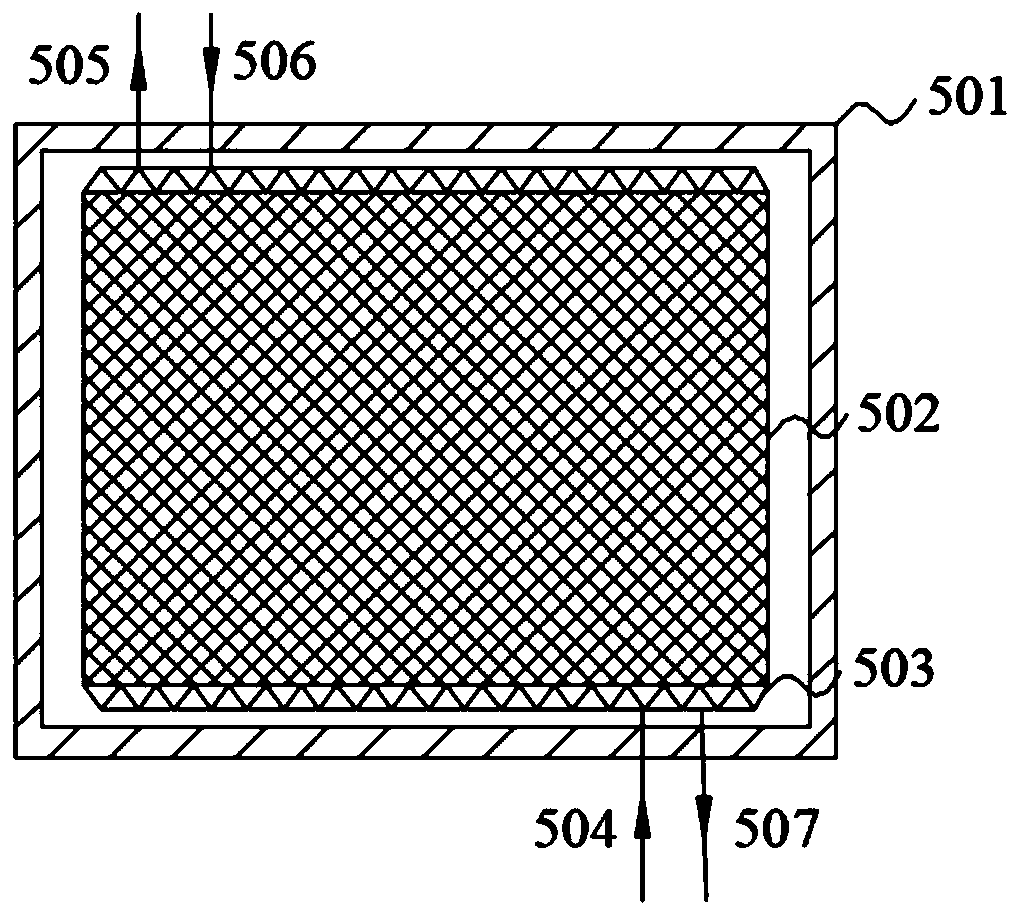

[0033] The first heat storage module 2 includes an air cooler 21 and a first heat storage device 22 arranged in series; the second heat storage module 4 includes an evaporator 41, a fan 43 and a second heat storage device 42, and the second heat storage device 42 is connected in series with the evaporator 41 through the throttling device 3; a first solenoid valve 6 and a second solenoi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com