Optical epoxy glue bonding strength test method and device for reflector

A technology for epoxy adhesive bonding and strength testing, which is applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of bonding angle, bonding area and bonding shape differences, and solve the problem of insufficient design and over-design , The effect of saving time cost and financial cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

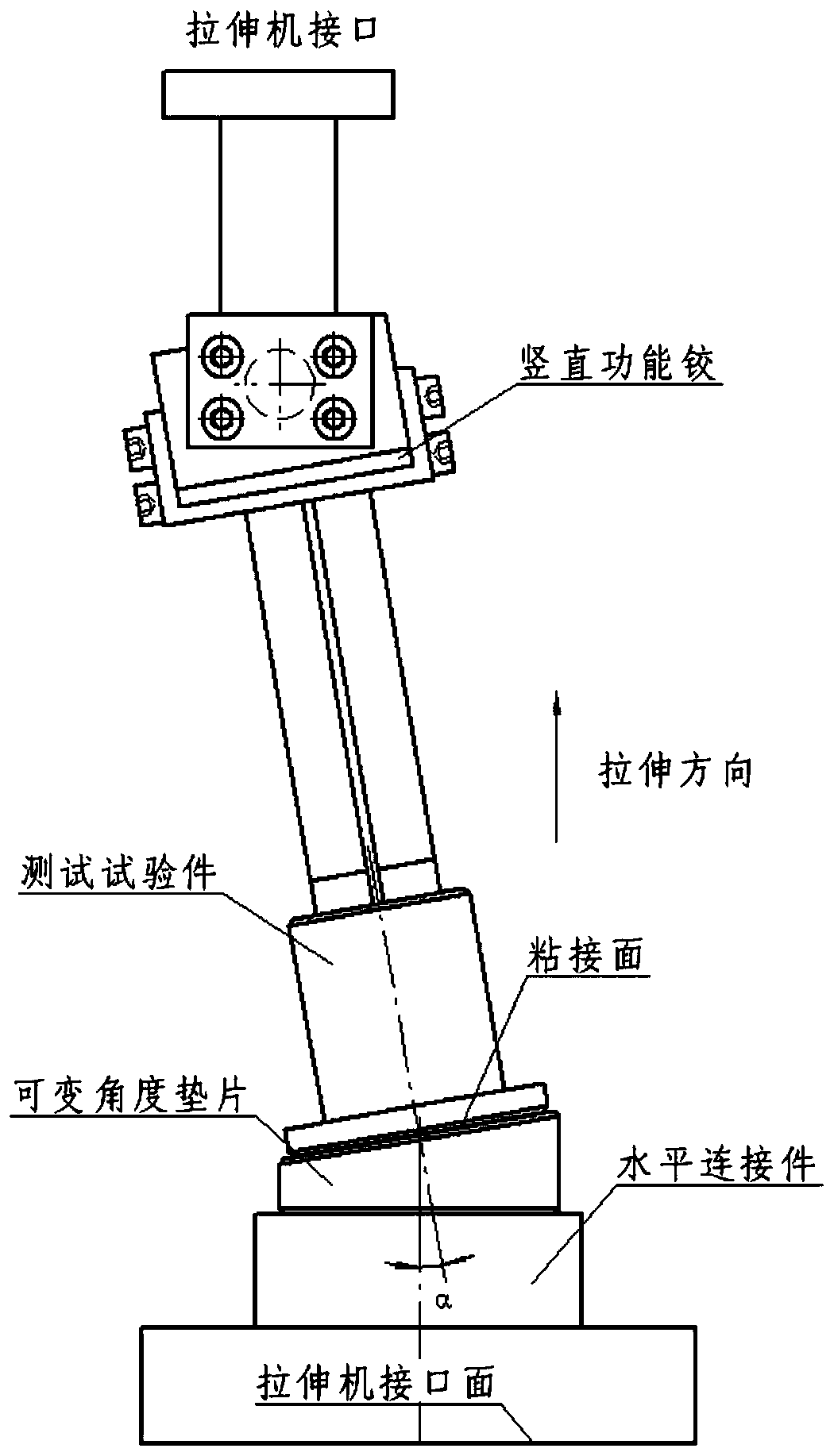

[0044] In this embodiment, the optical epoxy glue used is GHJ-01, the bonding angle of the optical epoxy glue for the mirror bonding support is 5°, and the surface roughness of the bonding surface is 5um to 10um. When adopting the application's optical epoxy adhesive bonding strength testing device to the reflector, the test method of the bonding strength of the above-mentioned optical epoxy adhesive under the use state is as follows:

[0045] S1: Determine that the bonding angle value of the optical epoxy glue is 5°, and control the inclination value of the variable-angle gasket to be consistent with the bonding angle value, which is 5°, and the inclination angle of the variable-angle gasket The error of the value is controlled within 5%;

[0046] S2: Treat the bonding surface of the test piece so that the surface roughness of the bonding surface of the test piece is consistent with the roughness of the bonding surface of the reflector, and prepare the bonding surface of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com