Pressure drop and flow uniformity monitoring system of PEMFC flow field plate

A flow field plate and uniformity technology, applied in the field of proton exchange membrane fuel cells, can solve the problems of damage to fuel cell life, membrane electrode failure, uneven membrane wetting state, etc., to prolong working life, avoid flooding or clogging, Guarantee the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

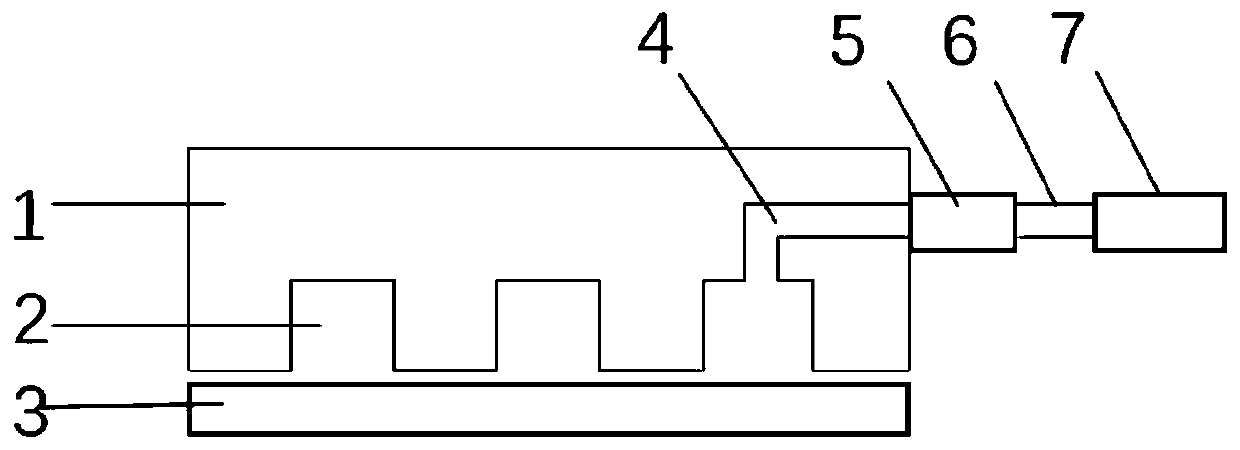

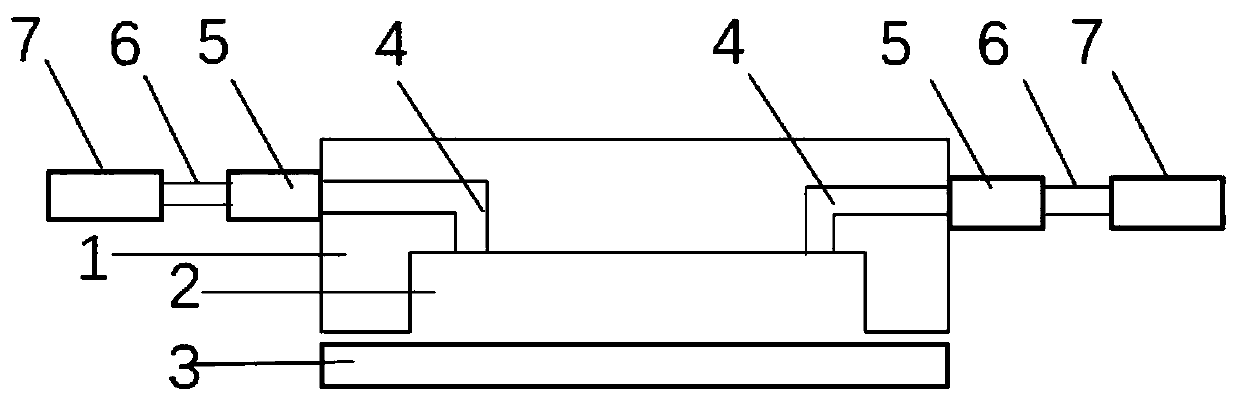

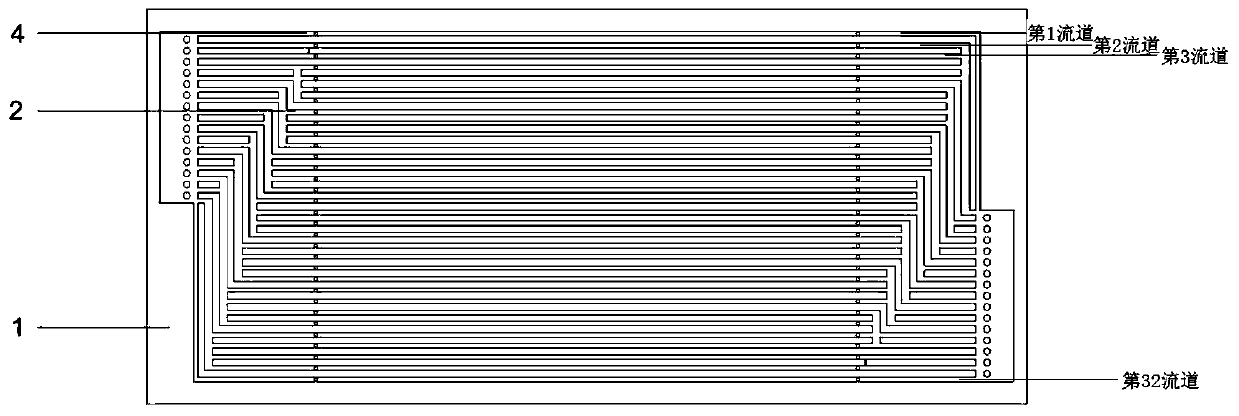

[0035] Such as image 3 A Z-shaped flow field plate 1 shown has a total of 32 gas flow channels 2 in sequence, a certain amount of reaction gas is passed into the flow field plate 1, and two lead-out channels 4 are opened on each flow channel 2 , connected to the pressure sensor 7 through the gas adapter 5, after the data is measured, the flow distribution is analyzed by the computer system. The reaction zone of the flow field plate 1 is a straight channel 2 channel, and the pressure drop data of each flow channel 2 of the flow field plate 1 measured by the formulas (1), (2) and (3) are shown in Table 1:

[0036] Table 1

[0037] Runner 1 2 3 4 5 6 7 8 Pressure drop / (cm water column) 14 10.3 11.6 5.4 7 5.5 5.5 5 Runner 2 9 10 11 12 13 14 15 16 Pressure drop / (cm water column) 5.7 6 5 4.5 3.5 4.4 4.4 4.5 Runner 17 18 19 20 21 22 23 24 Pressure drop / (cm water column) 4.3 4 5 4.1 4.2 3.8 5.5 5.5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com