Hydraulic mixing agitator

An agitator and hydraulic technology, which is used in mixer accessories, mixers with rotating mixing devices, mixers, etc., can solve problems such as deformation of floating disks, easy generation of static electricity, floating disk chucking and sinking disk phenomena.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

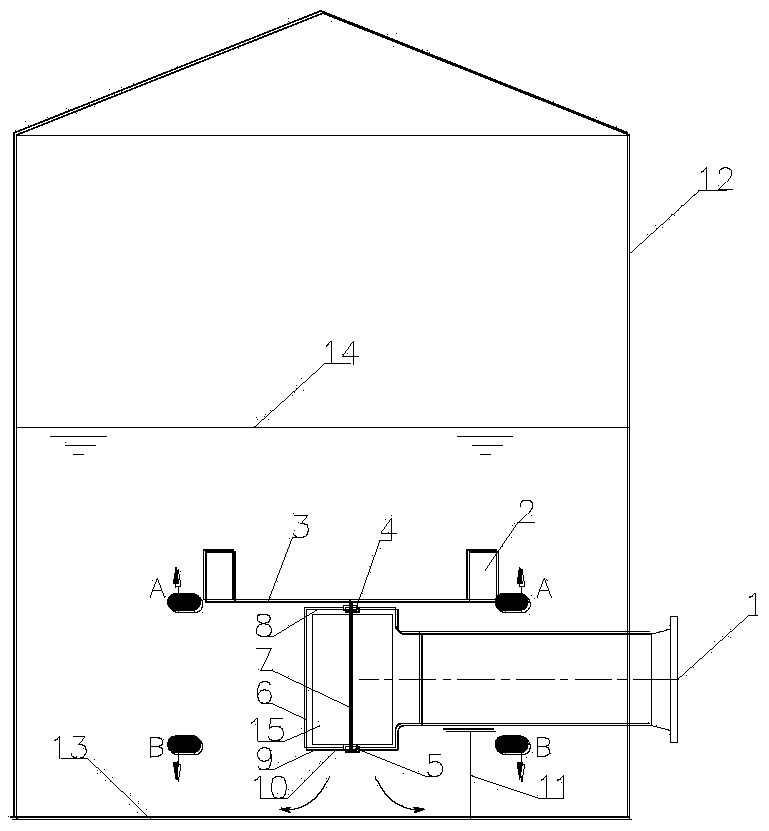

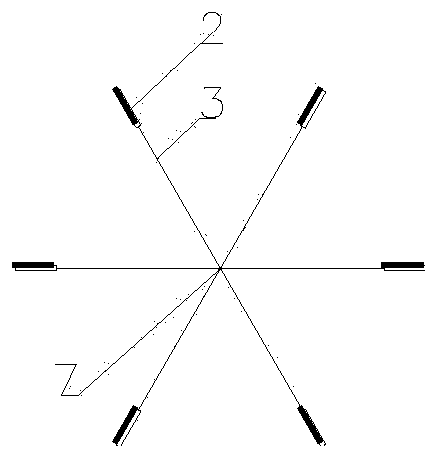

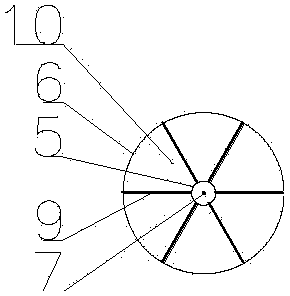

[0026] Such as Figure 1-Figure 4 As shown, a hydraulic blending agitator for a vertical oil storage tank 12 of the present invention includes an oil storage tank 12 and a hydraulic blending agitator, and the hydraulic blending agitator is fixed on the oil storage tank through a pipe bracket 11 In the tank 12, the hydraulic blending agitator includes an equal-diameter tee pipe 6, a rotating shaft 7, an upper bearing 4, a lower bearing 5, a paddle 15 and a stirring blade 2, and the main pipe of the equal-diameter tee pipe 6 is vertical Placement, the upper end is a sealing cover 8, the lower end is an oil outlet 10, a rotating shaft 7 is set at the center line position, the branch pipe of the equal diameter tee pipe 6 is connected to the feed pipe of the oil storage tank 12, and the inlet of the feed pipe is provided with an oil inlet 1. The rotating shaft 7 is placed vertically, and 3 to 5 paddles 15 are evenly distributed along the circumference of the rotating shaft 7. The h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com