Motor shell mold head for deep water pump

A technology for motor shells and deep water pumps, which is applied to casting molding equipment, molds, cores, etc. It can solve problems such as poor filling, fast solidification, and turbulent flow of molten metal, and is beneficial to shell making operations and structure The effect of reasonable design and reasonable solidification sequence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

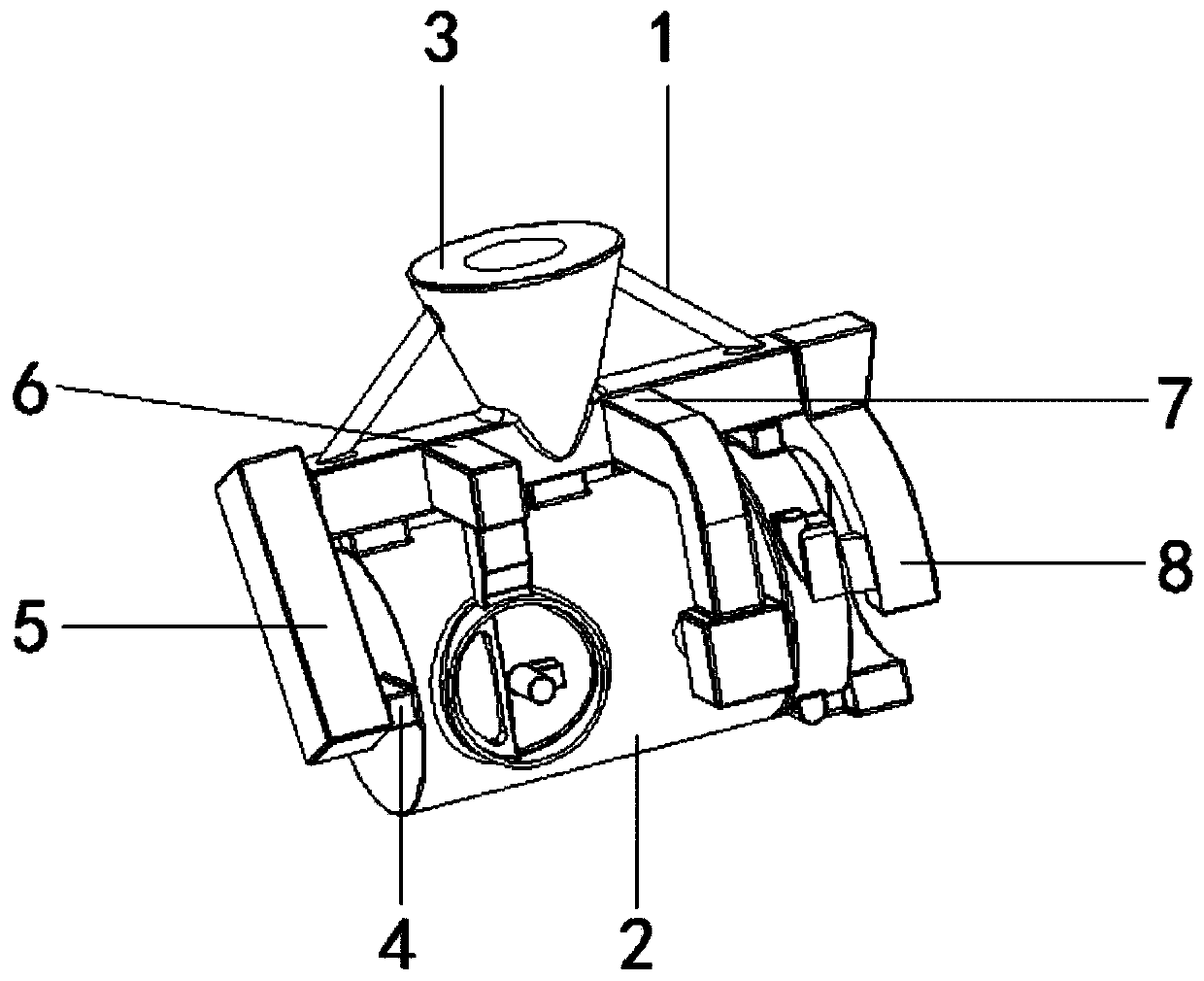

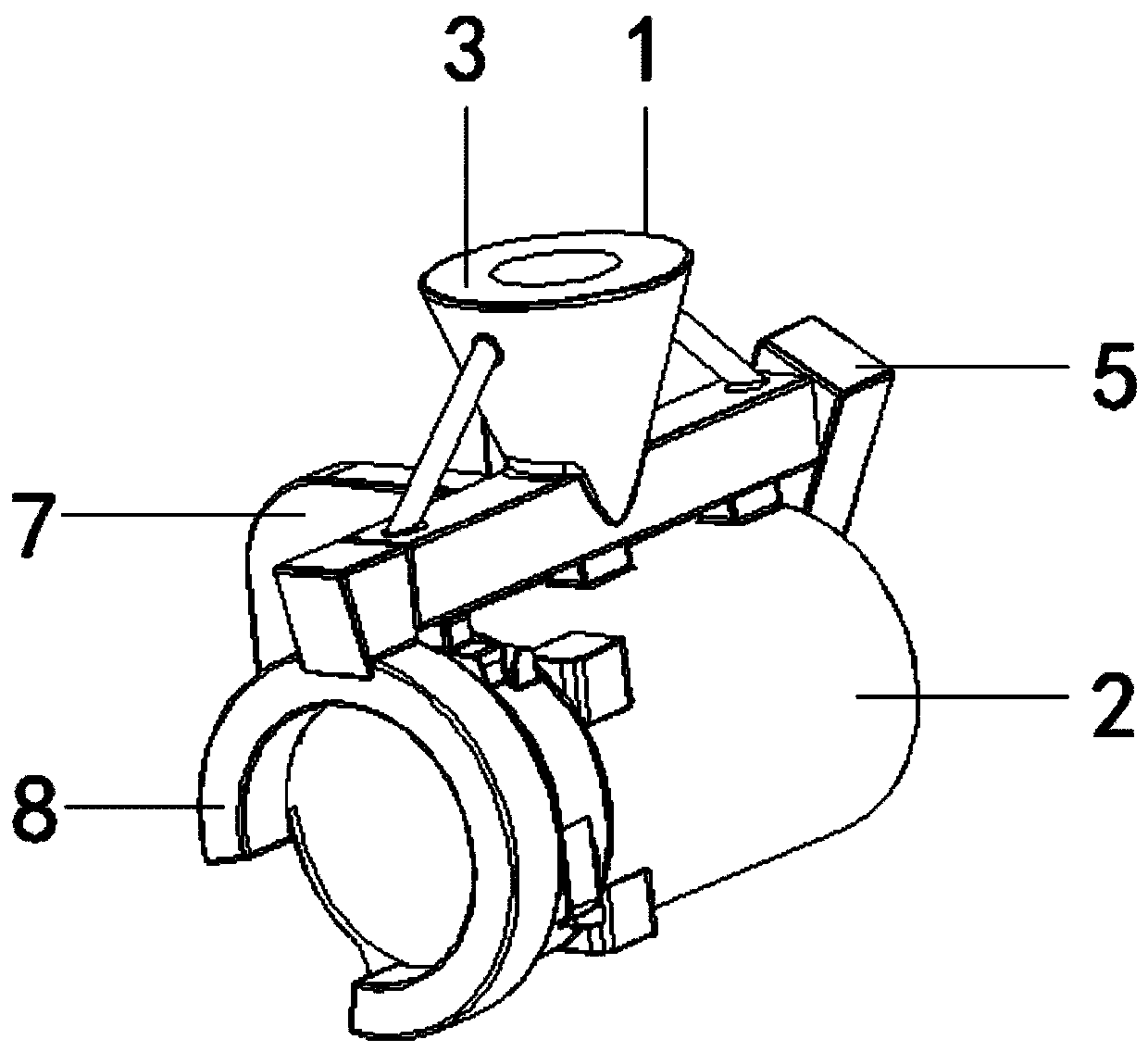

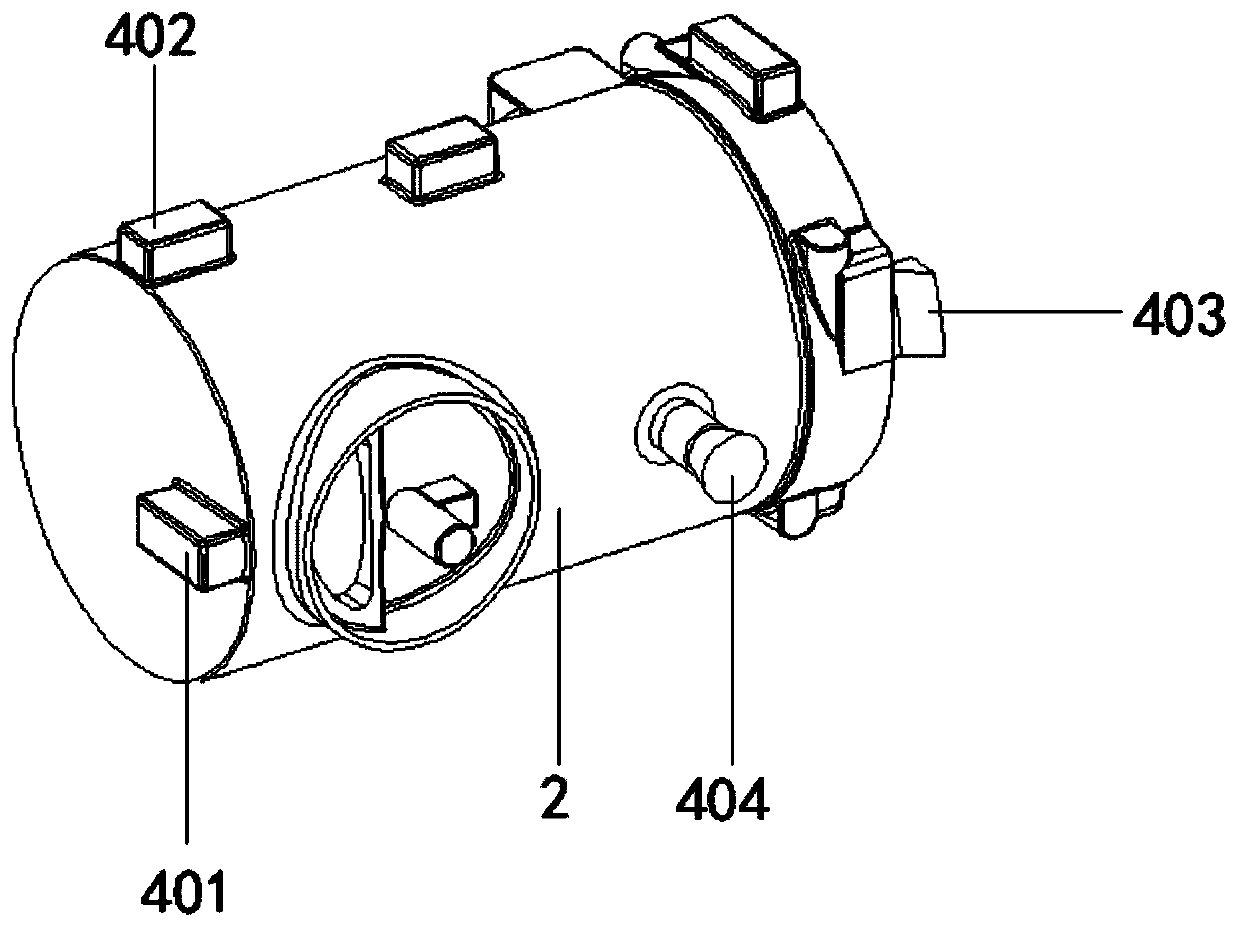

[0043] A motor casing die head for a deep water pump, comprising: a body 1, a motor casing wax piece 2, a die head 3, a gate 4, a back runner 5, a first side runner 6, and a second side runner 7. Front runner 8, rear gate 401, side gate 402, front gate 403, column gate 404; body 1 is provided with die head 3; motor shell wax part 2 is provided with several gates 4 , and the gate 4 and the wax part 2 of the motor shell are integrally formed through the wax mold; the rear end of the die head 3 is provided with a back runner 5, and the die head 3 and the back runner 5 are connected by wax sticking The front end of the die head 3 is provided with a front runner 8, and the die head 3 and the front runner 8 are connected by sticking wax; one side of the die head 3 is provided with a first side runner 6 and a second side runner 7 , and the first side runner 6 and the second side runner 7 are connected to the die head 3 by sticking wax; the gate 4 includes a rear gate 401 , a side gat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com