A collimator grid structure laser precision welding device and method

A laser welding and collimator technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., to achieve the effect of ensuring precise control, huge development potential, and eliminating defocus errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

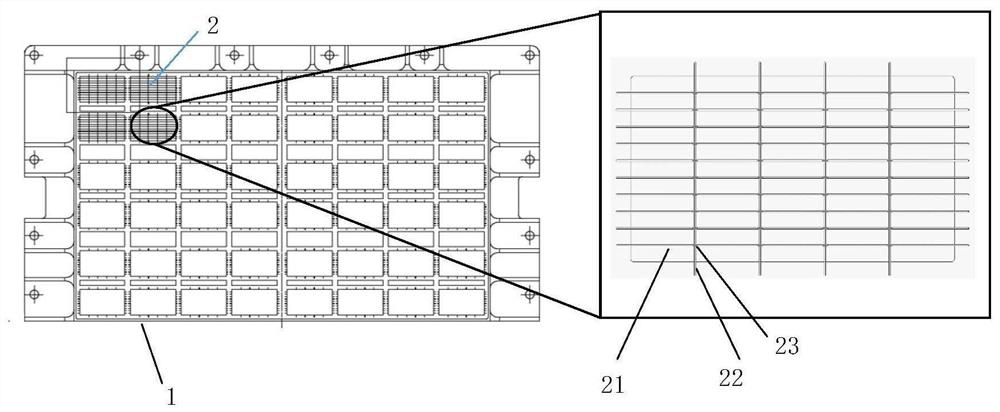

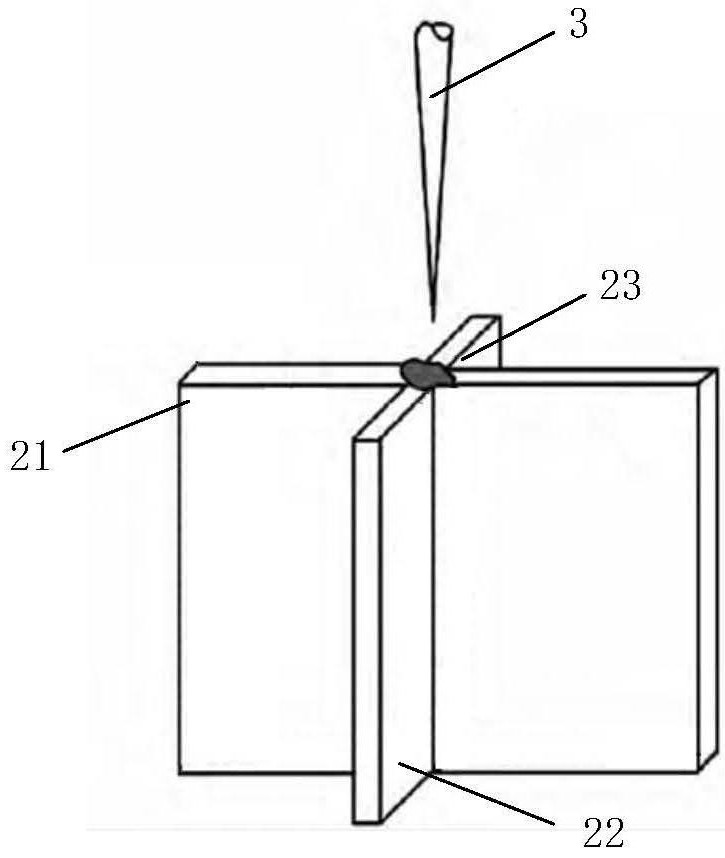

[0033] figure 1 It is a schematic diagram of a collimator grid structure 1 that needs to be welded in the present invention. It is mainly composed of a plurality of grid structure units 2, and each grid structure unit 2 is internally composed of numerous transverse metal foils 21, The vertical metal foil 22 is formed, and the intersection position of the horizontal and vertical metal foils is the welding position 23 . The length and width of a single grid structure are on the order of millimeters, and the material of the metal foil is usually selected from metals such as tungsten and tantalum, and the thickness is on the order of tens of microns. There are nearly 10,000 solder joints in each grid structure, and the parallelism and perpendicularity must be guaranteed within 1 angular minute. In a preferred embodiment, the material of the meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com