Smoke treatment device used for welding

A technology for processing devices and smoke, which is applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of inflexible operation, occupying precious resources, and the ineffective promotion and use of smoke purifiers, etc., to achieve enhanced effects, Increase the safety factor and realize the effect of miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the embodiments will be described in detail below with reference to the accompanying drawings. It should be noted that the following description only relates to the technical solution of the present invention and technologies directly related to the technical solution.

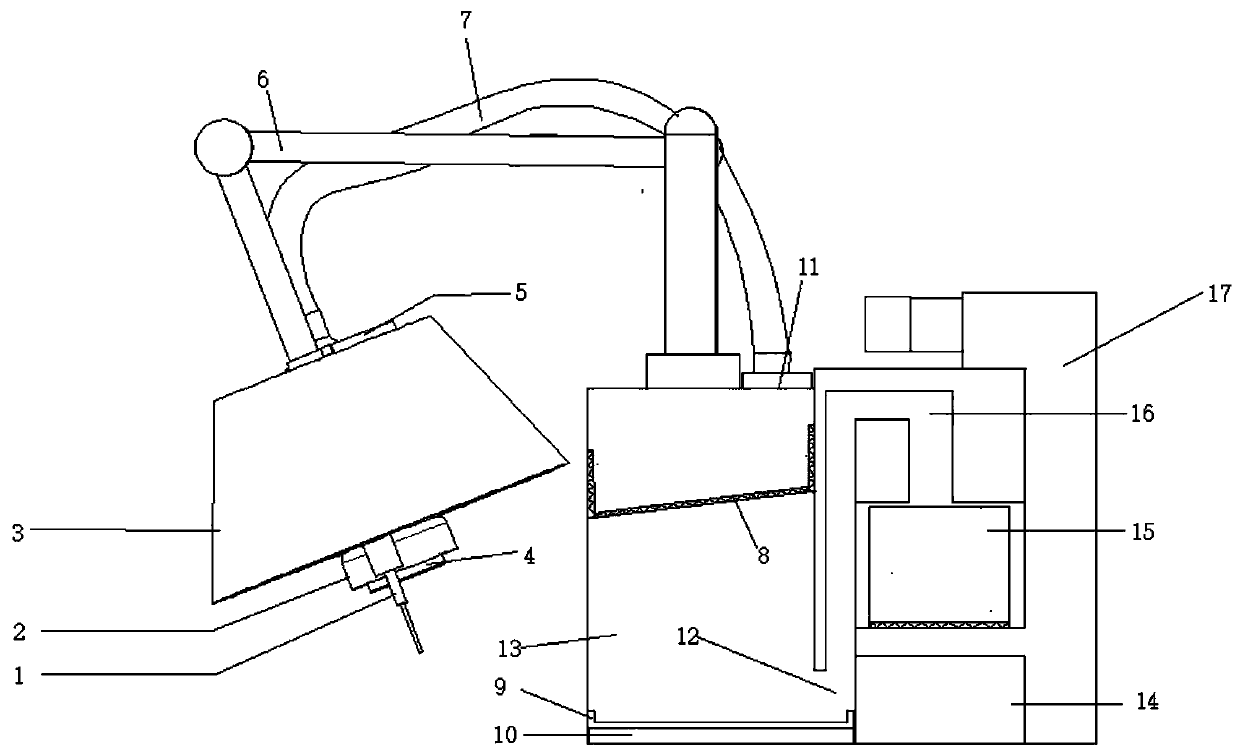

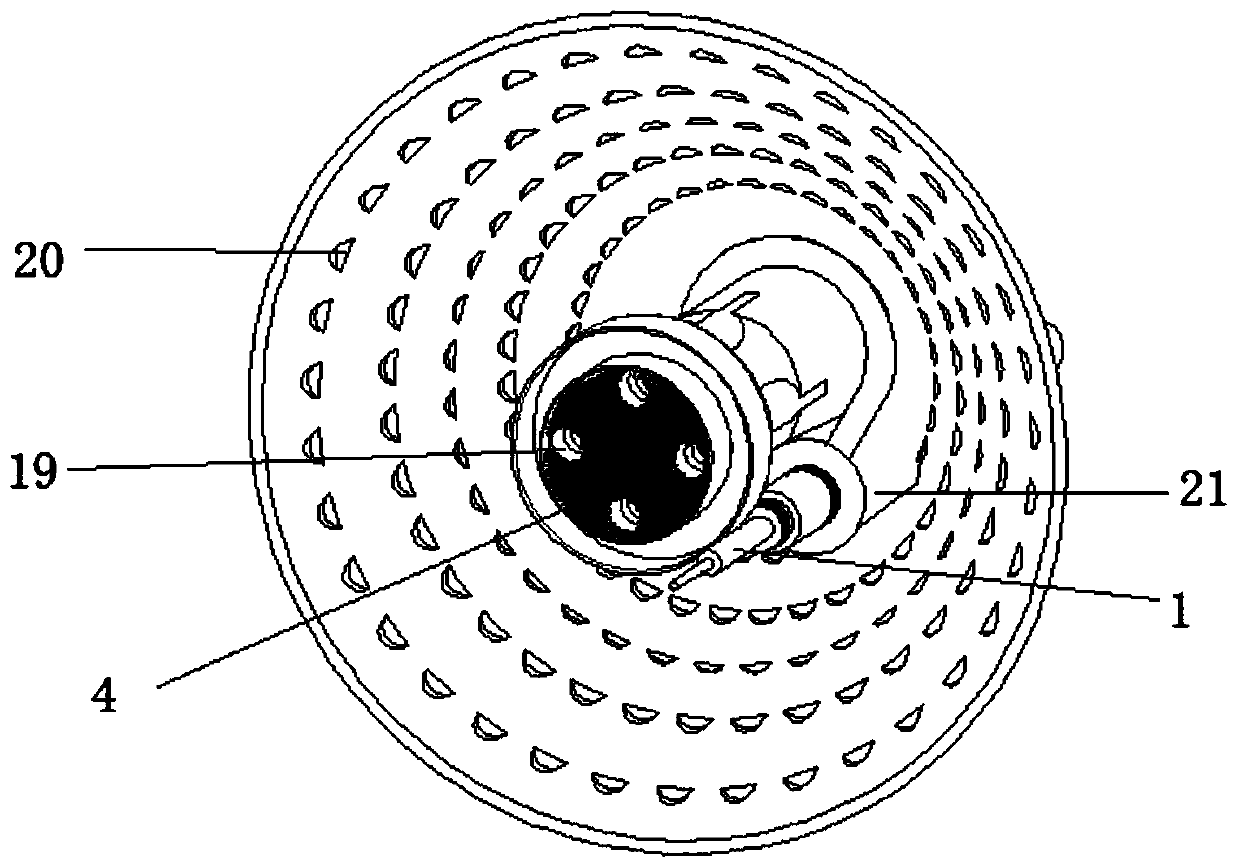

[0030] Such as Figure 1 to Figure 3 As shown, the present invention provides a welding fume treatment device, including: a grinding and dust suction module and a smoke and dust purification module. Pass;

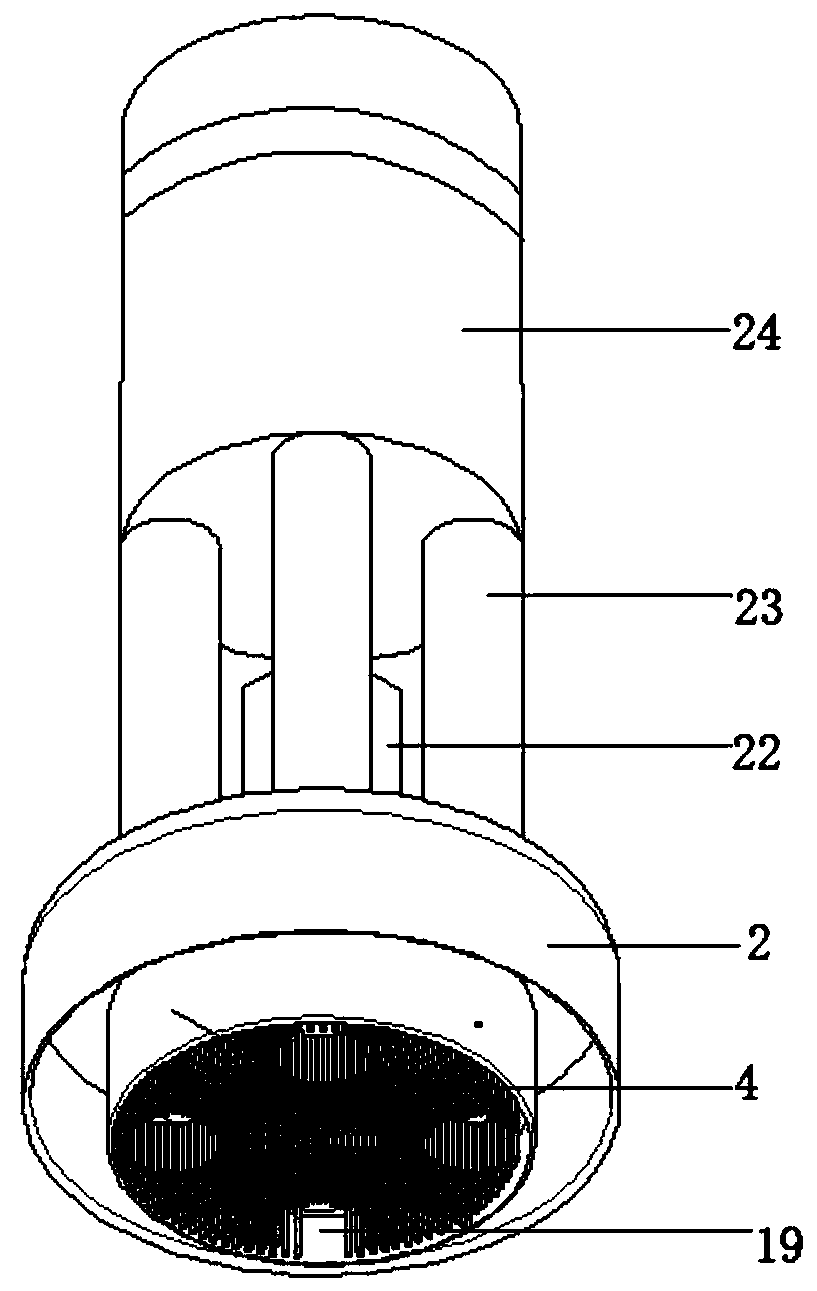

[0031] The grinding and dust collection module includes a double-layer vacuum cover 3, a protective cover 2, an industrial brush 4, a first air guiding part, a second air guiding part 24 and a drive motor 22, a protective cover 2, a first air guiding part, a second The air guiding part 24 and the double-layer vacuum cover 3 are sequentially connected and internally conducted. An ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com