Electron beam curing shielding device allowing continuous feeding of plates

A technology of electron beam curing and shielding device, which is applied in shielding, packaging, transportation and packaging, etc., can solve the problems of consuming large space and production costs, and achieve the effects of improving production efficiency, speeding up moving speed, and preventing radiation leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

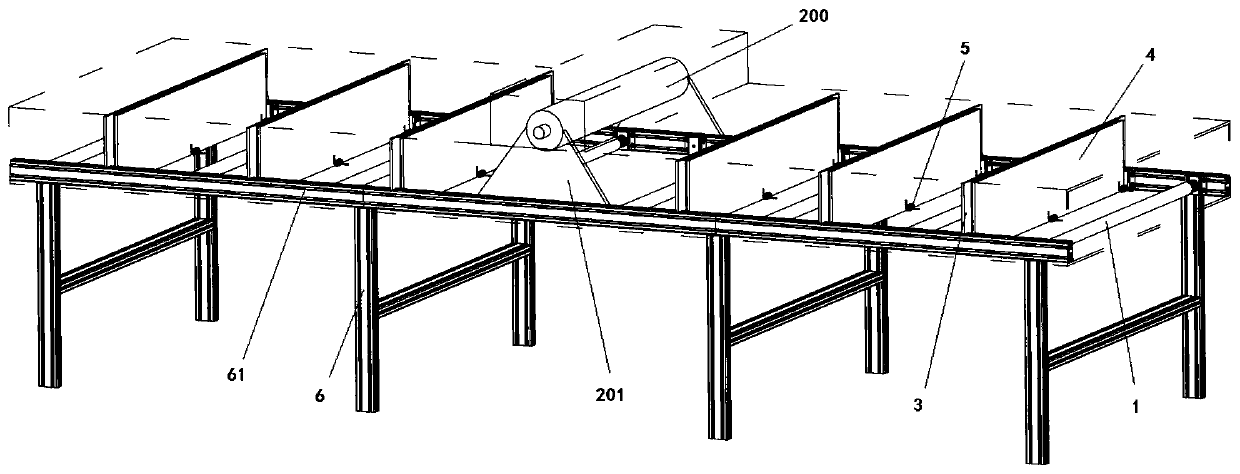

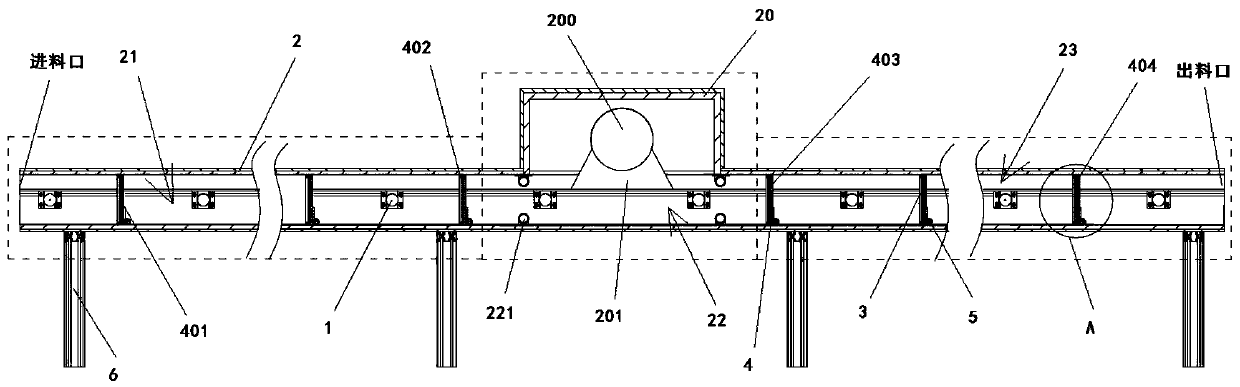

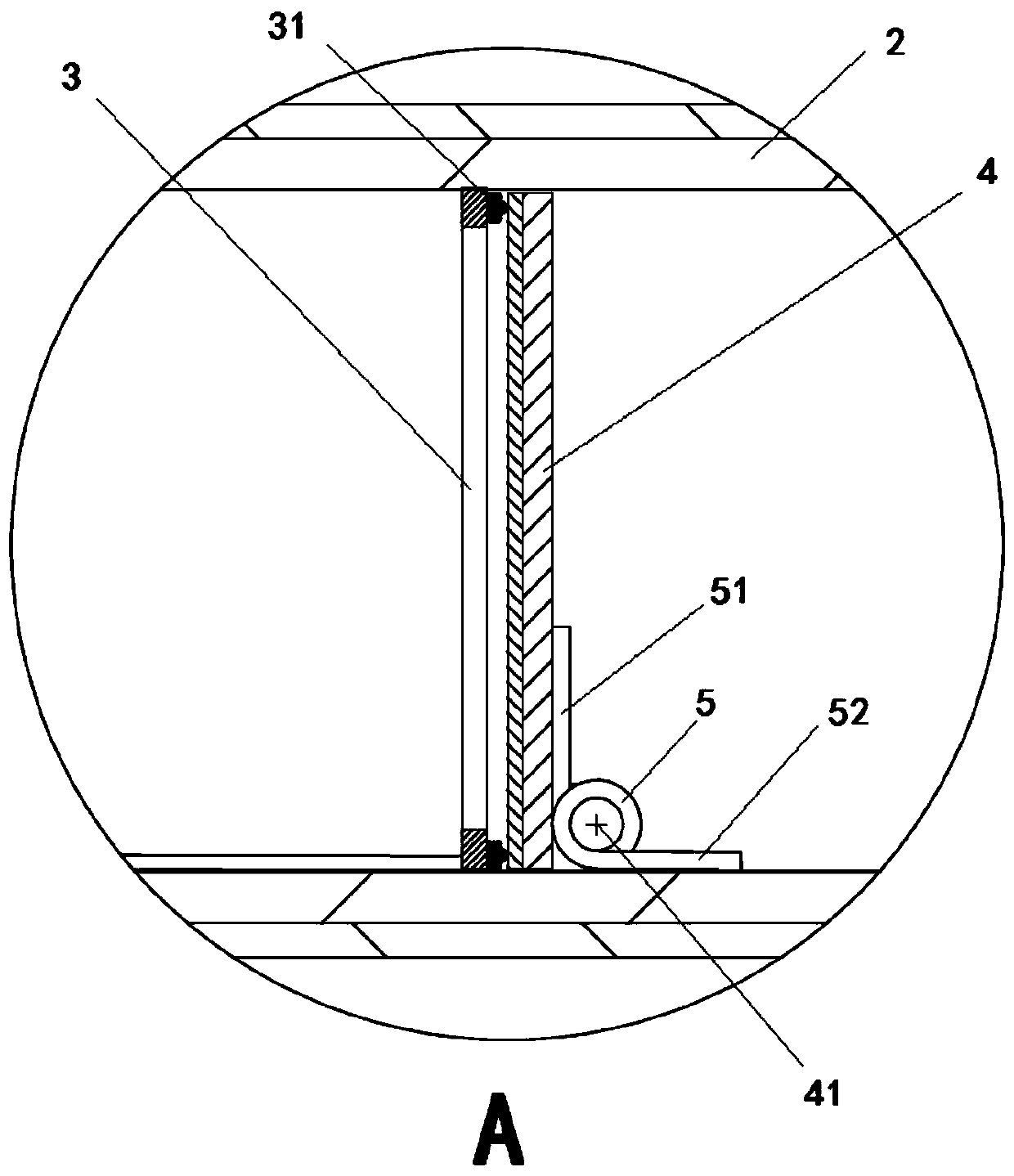

[0033] An embodiment of the present invention provides an electron beam curing shielding device for continuous feeding of plates, such as figure 1 and figure 2 As shown, it includes a conveying assembly 1 for conveying the plate 100 . The conveying assembly 1 includes a plurality of conveying rollers arranged at intervals. The conveying rollers rotate by themselves, thereby driving the plate 100 to move forward. Usually, the board 100 is a board-like structure with a relatively regular structure, its length direction is parallel to the conveying direction, and the distance between two adjacent conveying rollers is much smaller than the length of the board 100 . In order to improve the smoothness of the conveying process, all conveying rollers can be located on the same plane, so as to convey the plate 100 in a straight line. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com