Double-output transmission box and ampoule bottle horizontal-to-upright turnover device applying double-output transmission box

A transmission box, double output technology, applied in the direction of transmission, transportation and packaging, conveyors, etc., can solve the problems of ampoules, explosive bottles, poor effect, and inability to print on ampoules. Prevent bottle explosion and avoid free fall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

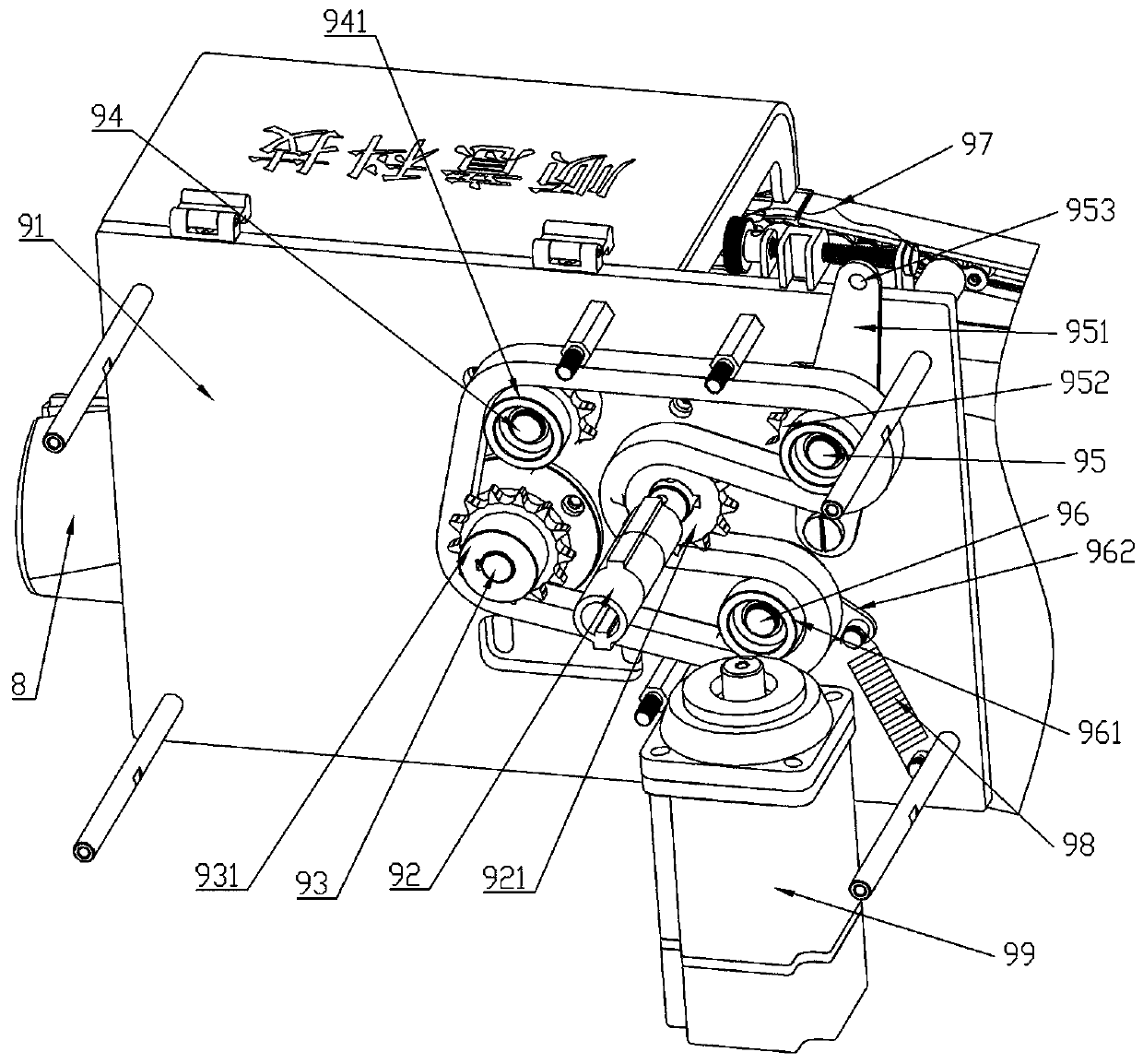

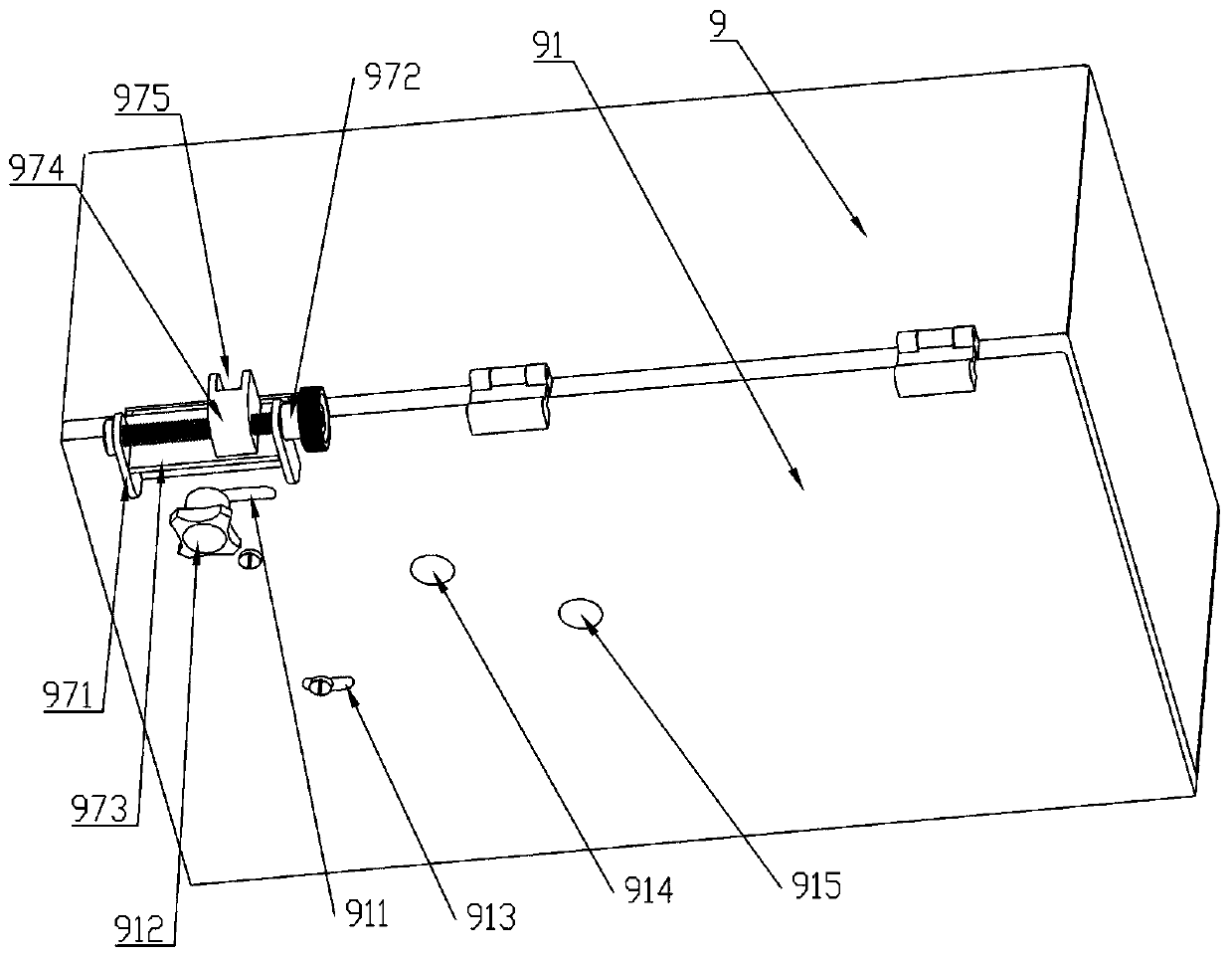

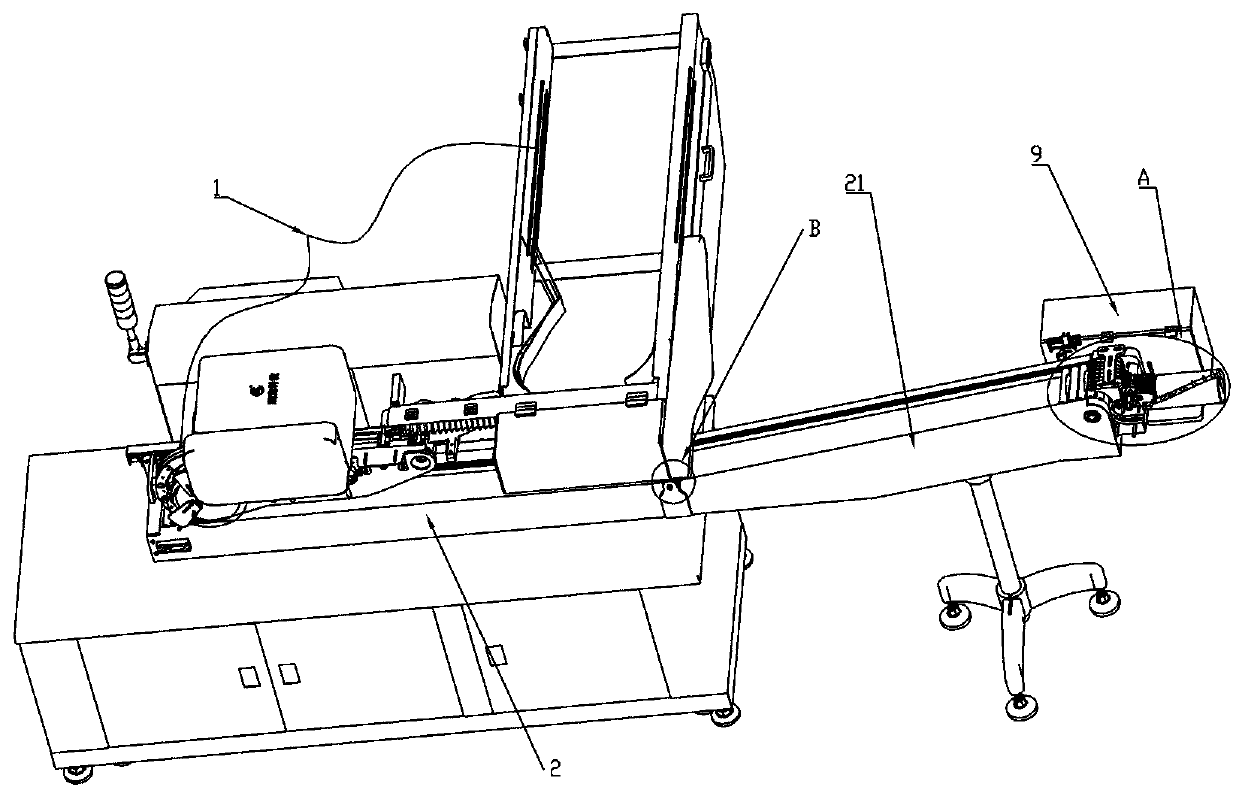

[0026] The specific embodiment of the present invention sees Figure 1-5 :

[0027] A dual output gearbox 9, such as figure 1 with 2 , including a motor 99 and a reducer that are fixedly installed inside and matched together. One side of the transmission box 9 is a transmission mounting plate 91 for installing the first output shaft 92 and the second output shaft 93. The first output shaft 92 is connected to the reducer. , the driving sprocket 921 and the driven sprocket 931 are respectively installed on the first output shaft 92 and the second output shaft 93, and the driving sprocket 921 and the driven sprocket 931 follow the first output shaft 92 and the second output shaft respectively 93 rotations, the transmission mounting plate 91 is provided with the first shaft hole 914 and the second shaft hole 915 respectively for the first output shaft 92 and the second output shaft 93 to pass through, and the transmission mounting plate 91 is also equipped with a reversing shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com