Cast-in-situ bored pile structure and construction method thereof

A technology of bored cast-in-place piles and cast-in-place holes, which is applied in basic structural engineering, sheet pile walls, buildings, etc., can solve the problems of uneven friction of steel casings, reducing the quality of cast-in-place piles, and poor verticality of steel cages. Achieve the effect of improving stability and final forming quality, improving stable guiding effect, and small axis offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

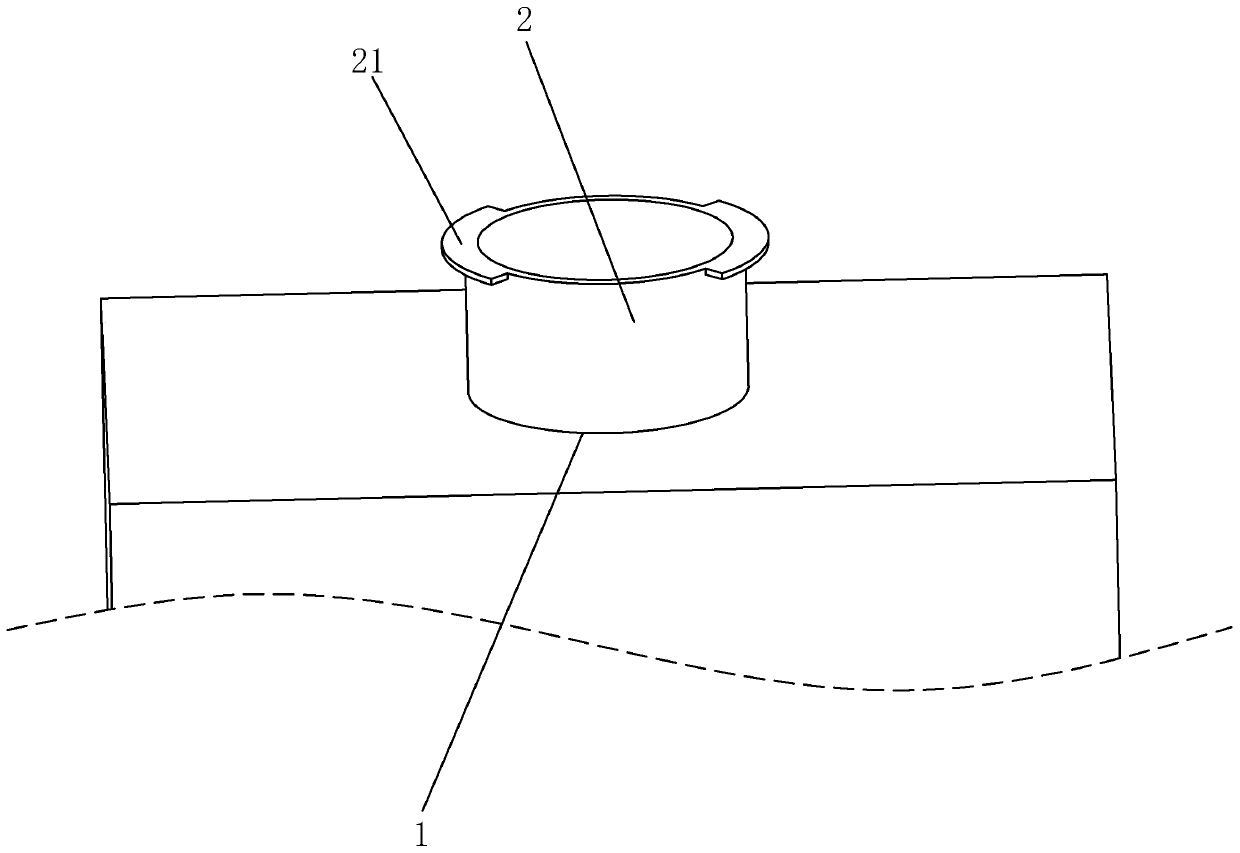

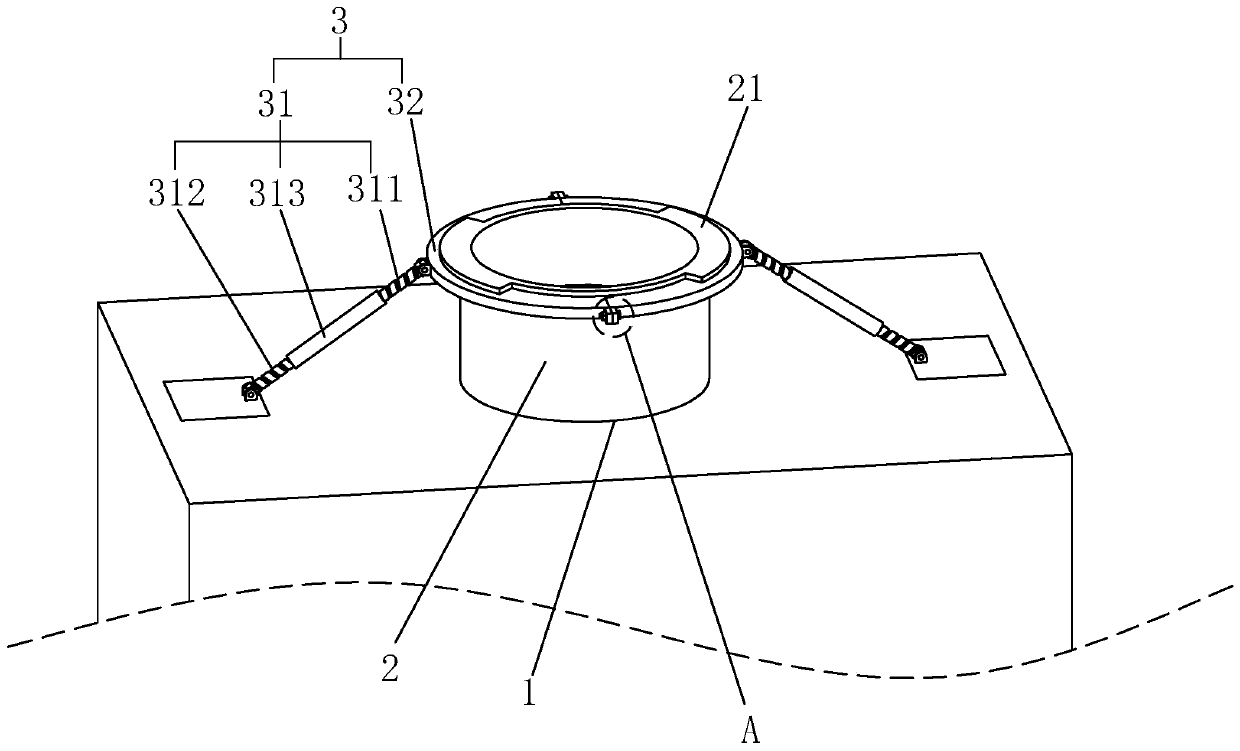

[0044] A bored pile structure, such as Figure 4 As shown, it includes the filling hole 1 opened on the ground. A steel casing 2 is inserted at the top opening of the filling hole 1. The steel casing 2 is attached to the inner wall of the filling hole 1. A reinforcement cage 5 is provided, and the reinforcement cage 5 passes through the steel casing 2 from top to bottom, and the outer surface of the steel casing 2 is clamped with a positioning assembly 3 for preventing the steel casing 2 from settling. During construction, first dig a hole on the ground and bury the steel casing 2, then continue to dig holes along the inside of the steel casing 2, and then put the reinforcement cage 5 into the pouring hole 1 along the steel casing 2 after the hole is dug. In the process of lowering the reinforcement cage 5, the positioning component 3 can fix the steel casing 2, so that the lowering stability of the reinforcement cage 5 is higher, thereby improving the final forming quality of...

Embodiment 2

[0051] A construction method for a bored pile structure, comprising the following construction steps:

[0052] S1. Clean up the ground and tamp the position where the cast-in-situ pile needs to be formed, and prefabricate the reinforcement cage 5 in advance;

[0053] S2. Drill a hole with a depth of 2-4m and bury a steel casing 2. The inner diameter of the steel casing 2 is selected to be 20-40cm larger than the pile diameter;

[0054] S3, two vertical guide columns 4 are set around the drilled holes to ensure that the distances between the two guide columns 4 and the axis of the steel casing 2 are equal;

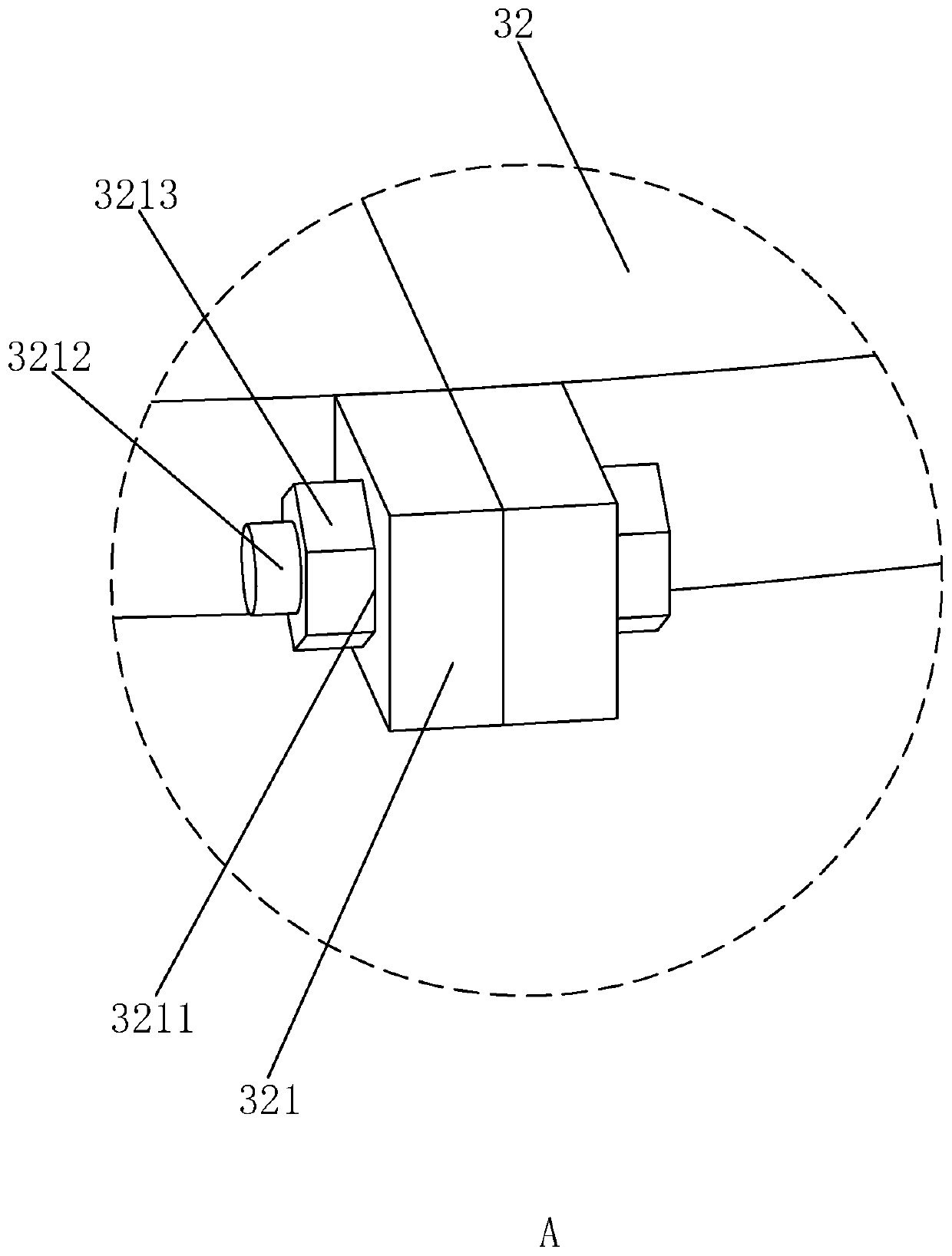

[0055] S4. Install the positioning component 3: connect the second adjusting screw 312 to the ground hinge, then abut the positioning ring 32 on the outer wall of the steel casing 2 and ensure that the top of the positioning ring 32 is in contact with the blocking piece 21, and lock the bolt 3212 After passing through the locking hole 3211, screw on the locking nut 3213; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com