Parking brake

A parking brake and brake bottom plate technology, applied in the direction of brake types, brake components, brake actuators, etc., can solve the problems of critical driving safety, difficult operation of the driver, long stroke of the parking handle, etc., to ensure driving safety performance, saving internal space, and improving transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

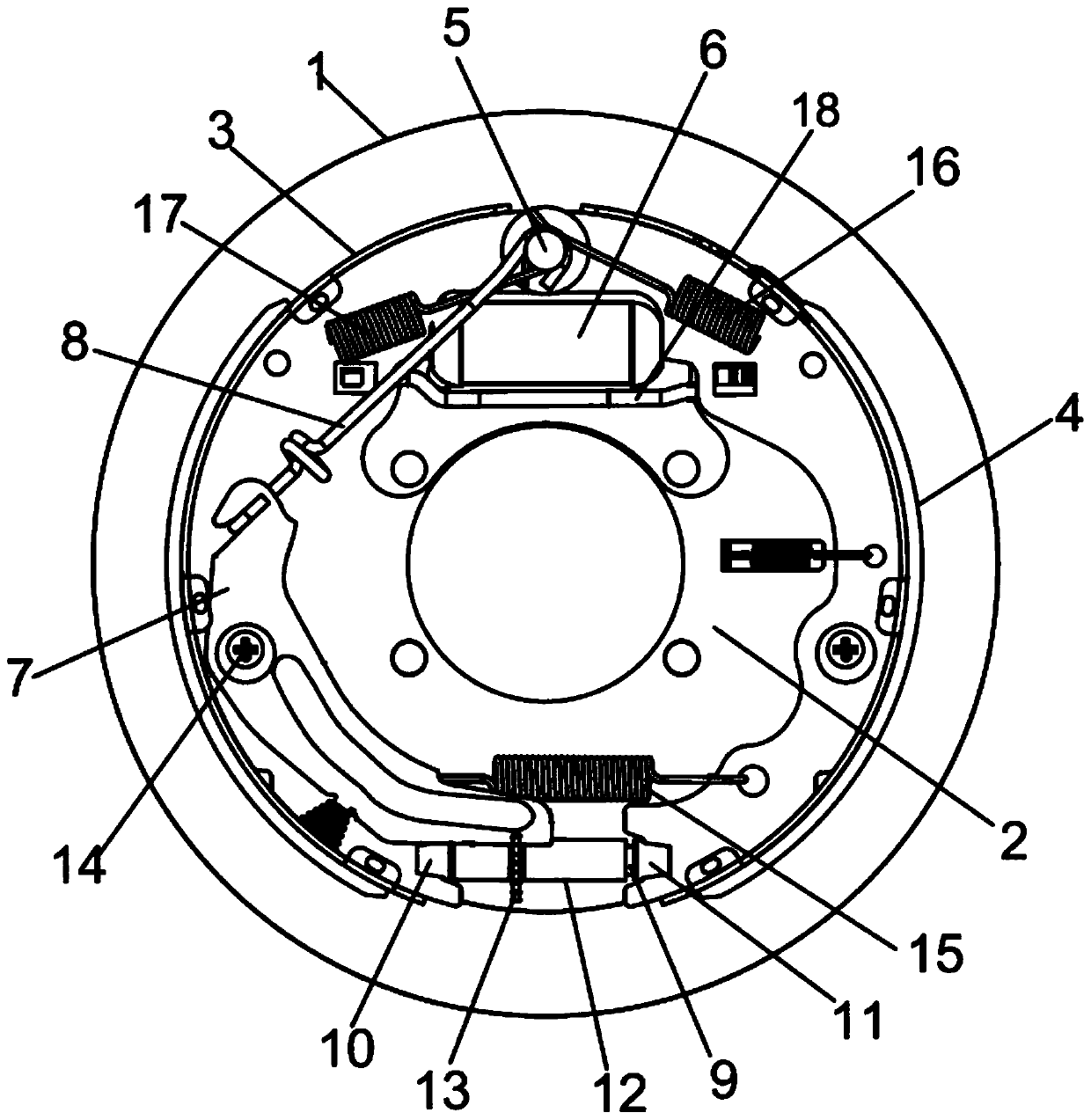

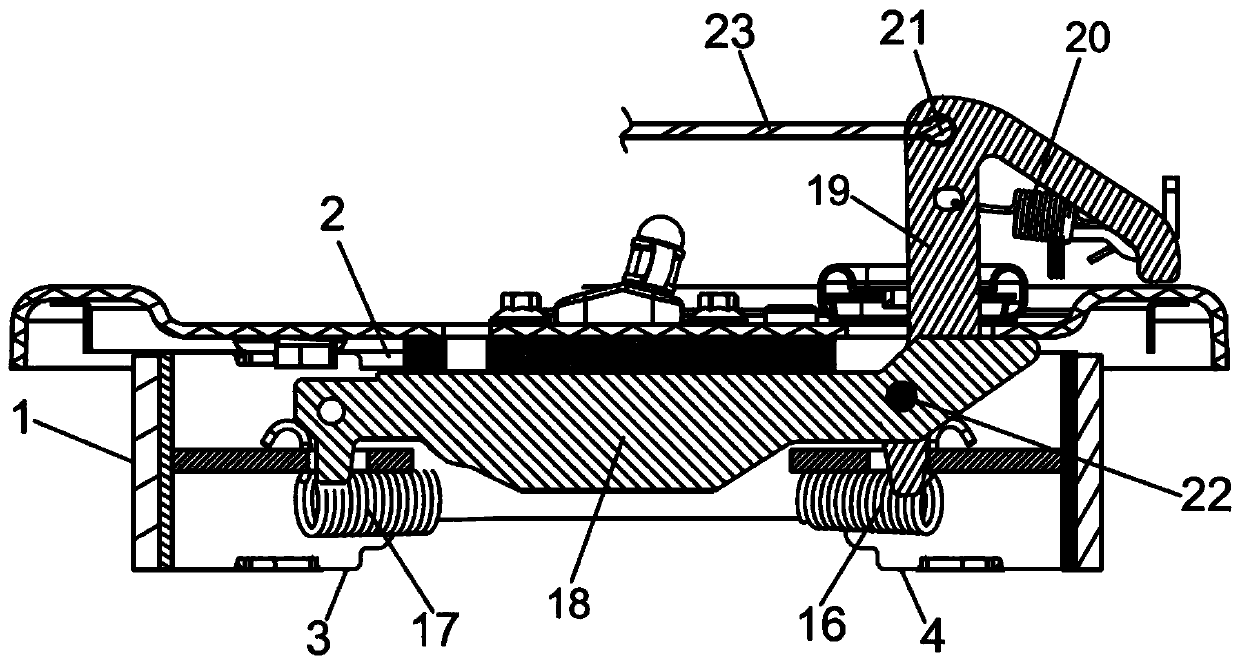

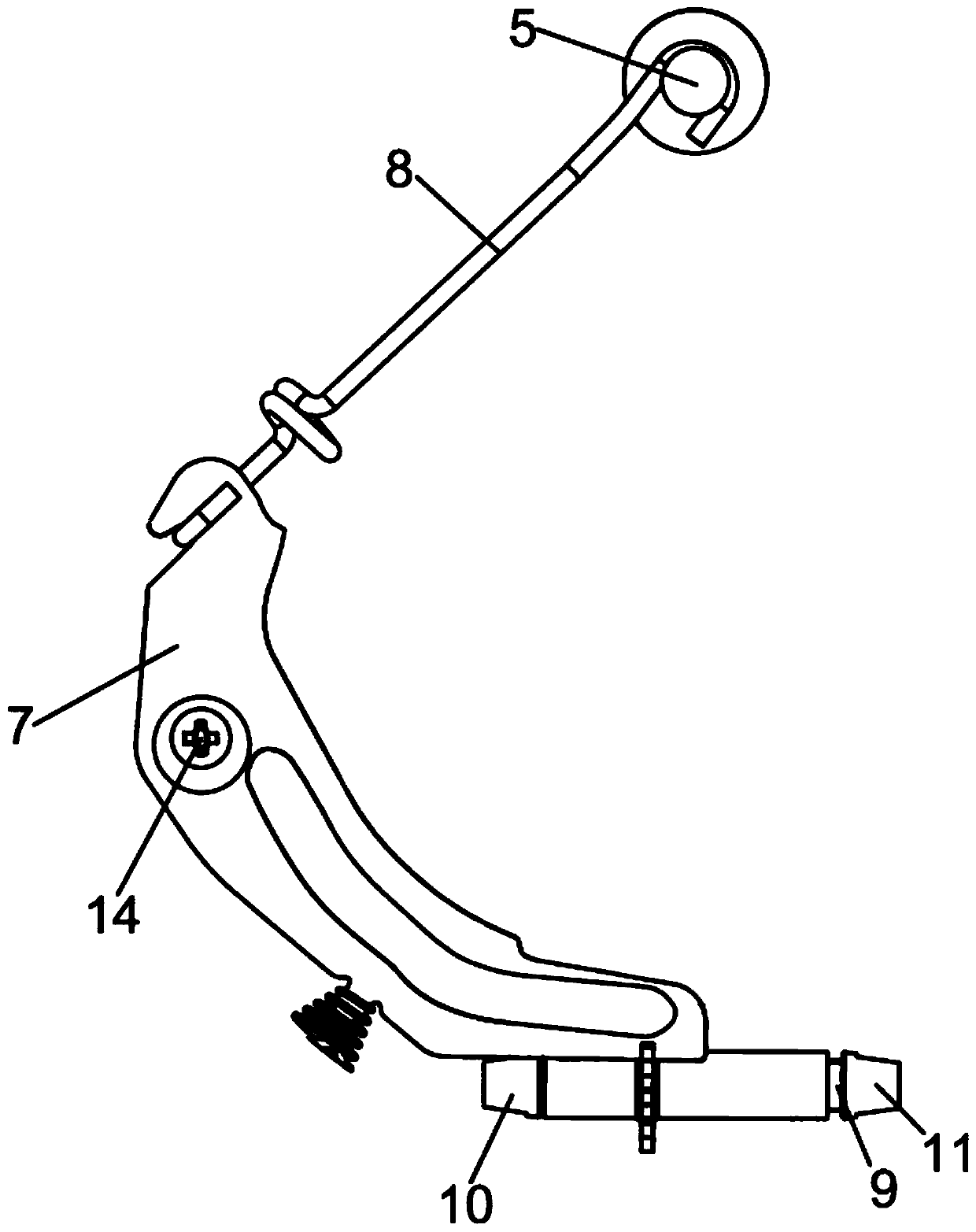

[0019] Depend on Figure 1-5It can be known from the illustrated embodiment that this embodiment includes a parking motion mechanism and a brake device, the brake device includes a brake drum 1 with an inner circular friction surface, the brake leading shoe 3 and the brake slave shoe 4 are arranged symmetrically from left to right On the brake bottom plate 2, so that the arc-shaped friction plates of the brake leading shoe 3 and the brake slave shoe 4 correspond to the inner circular friction surface of the brake drum 1, the brake leading shoe 3 and the brake slave shoe 4 The position between the corresponding upper ends is provided with a support pin 5, and the support pin 5 is fixed on the brake base plate 2. The parking motion mechanism includes a push plate 18, a brake pull arm 19, a pull arm return spring 20 and a brake pull. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com