Bidirectional throttle valve

A two-way throttling valve and throttling technology, which is applied in the direction of safety valves, balance valves, valve devices, etc., can solve problems such as the two-way flow of throttle valves is not smooth, and achieve the effects of reducing structure, ensuring stability, and improving reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

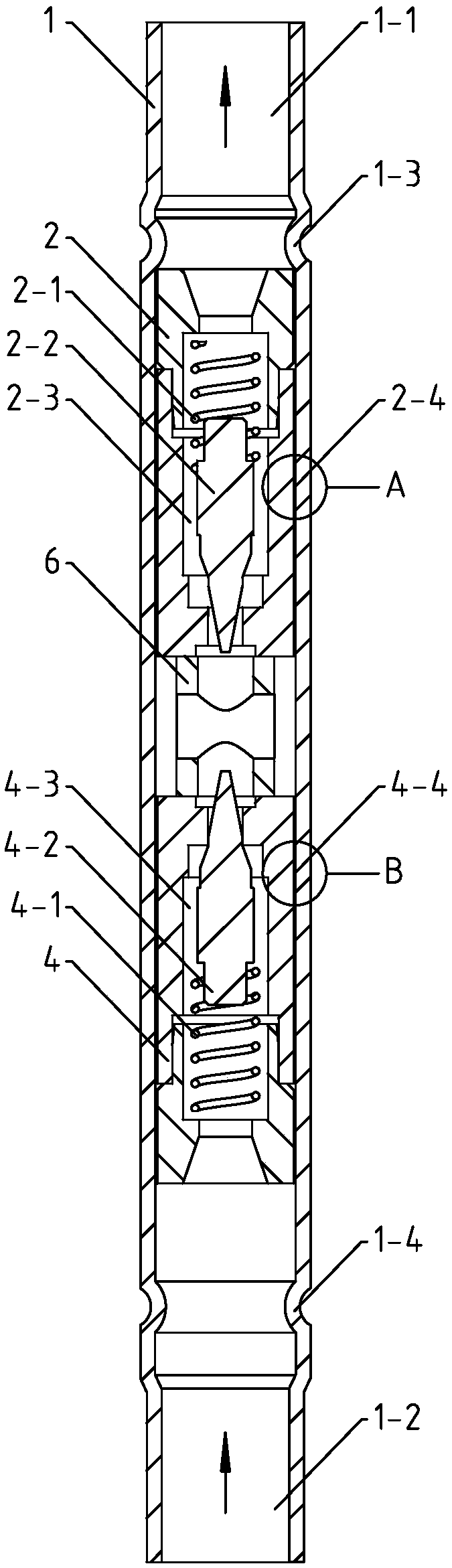

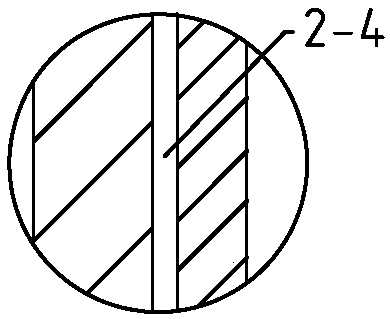

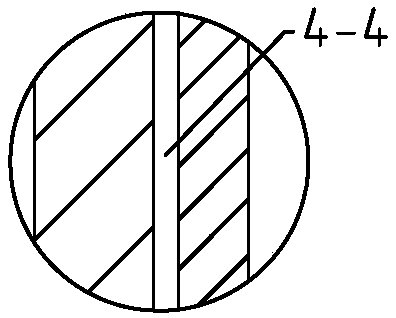

[0039] A two-way throttle valve described in the embodiment of the present invention, such as figure 1 As shown, it includes a valve pipe 1, a first valve body 2 and a second valve body 4 arranged in the valve pipe 1, the first valve body 2 is provided with a first throttling passage 2-3, and the first throttling passage 2- 3 is installed with the first valve needle 2-2 and the first spring 2-1, the first spring 2-1 pushes the first valve needle 2-2 to move in the direction of closing the first throttle passage 2-3, correspondingly, The second valve body 4 is provided with a second throttling passage 4-3, and a second valve needle 4-2 and a second spring 4-1 are installed in the second throttling passage 4-3, and the second spring 4-2 pushes the first The second valve needle 4-2 moves toward the direction of closing the second throttling passage 4-3. Such as figure 2 As shown, a first guide channel 2-4 is formed between the first valve body 2 and the valve tube 1, as imag...

Embodiment 2

[0048] The difference between the embodiment of the present invention and embodiment 1 is that, as Image 6 As shown, the first guide channel 2-4 spirally extends along the axial direction of the first valve body 2 on the outer wall of the first valve body 2. When the first valve body 2 is in the second throttling position, the medium passes through the first guide The channel 2-4, through the helically extended first guide channel 2-4, can make the medium generate an axial force on the first valve body 2 when passing through the first guide channel 2-4, so that the first valve body 2 is more stable in the second throttle position and will not move easily. It can be understood that the second guide passage 4-4 can also extend spirally along the axial direction of the second valve body 4 on the outer wall of the second valve body 4, and when the second valve body 4 is in the first throttling position, the medium passes through the second valve body 4. The second guide passage ...

Embodiment 3

[0054] Such as Figure 7 As shown, the difference between the embodiment of the present invention and embodiment 1 is that the first flow guide channel 2-4 and the second flow guide channel 4-4 are located on the inner wall of the valve tube 1, and the first flow guide channel 2-4 and the second flow guide channel The channel 4 - 4 extends helically along the axial direction of the valve tube 1 . The first guide channel 2-4 and the second guide channel 4-4 are directly formed on the inner wall of the valve tube 1, which is convenient for production and processing, and improves the versatility of the first valve body 2 and the second valve body 4, which is convenient for replacement and maintenance , thereby reducing costs.

[0055] Such as Figure 14 As shown, the bracket 6 can be located on the end of the second valve body 4 facing the first valve body 2 . The bracket 6 is provided with a radial communication groove 9-1 and an axial communication hole 9-3, the radial commu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com